So, I switched balance chambers to see what the difference in minimum cracking effort was (knob fully out position). The difference in base height as measured by @Open Ocean Diver was 0.024"/0.6mm. That's less than a half turn on the knob. I started with the old style, shorter base chamber and a cracking effort of 1.05". Sure enough, when I put the taller base balance chamber in my G250, the min cracking effort went from 1.05" to 1.12" measured with the precision cracking effort pump. It all makes sense, if not really significant. On the other hand, I'd rather be able to get 1" min on my G250 than 1.1", so there's that.

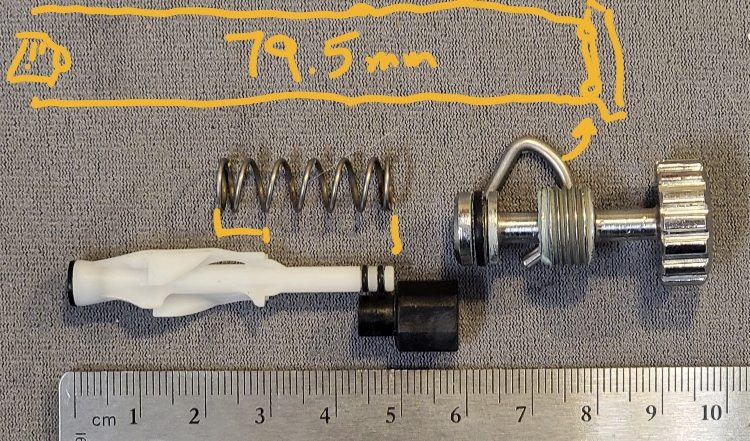

As for which balance chamber clears the wiper o-ring, here's a picture:

As you can see, in my reg, there's 79.5mm clearance from the knife edge of the orifice to the locking pin hole in the barrel.

When the pieces are set out at that distance with the old balance chamber, the wiper o-ring is just inside the crown, and thus performing its function. More surprising is the amount of compression on that poppet spring. It's fully 1/3 compressed in its least compressed position.

My conclusion? For the G250 at least, it doesn't matter which balance chamber you use, unless you want below spec cracking effort (which I do ).

).

One of these days I'll take a look at the G260...

As for which balance chamber clears the wiper o-ring, here's a picture:

As you can see, in my reg, there's 79.5mm clearance from the knife edge of the orifice to the locking pin hole in the barrel.

When the pieces are set out at that distance with the old balance chamber, the wiper o-ring is just inside the crown, and thus performing its function. More surprising is the amount of compression on that poppet spring. It's fully 1/3 compressed in its least compressed position.

My conclusion? For the G250 at least, it doesn't matter which balance chamber you use, unless you want below spec cracking effort (which I do

One of these days I'll take a look at the G260...