Found it after some search keywords refinements, thanks for that heads up and a  for remembering @rhwestfall

for remembering @rhwestfall

For completeness sake:

For completeness sake:

I had gotten a G250 off the used market, that had "official" serviced labels on it (the place used a custom hose protector with the shop name, and date of service). I quickly serviced it, and just couldn't get it to work.... As I looked at my parts supply for options, it dawned on me that the only times I had seen 109/156, g250 & G250v orifices, they were stainless steel or plastic, and this one wasn't.... It was then that I compared it to a known one, and SURPRISE!!!!!, it is shorter.

As I said, I don't have my schematics handy, but the only other "brass" orifice I have seen [edit - I thought I have seen] was in a G200/G200b.

Anyhow, here are the two:

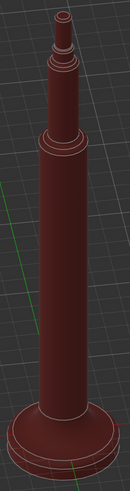

Proper height:

View attachment 378703

Problem height:

View attachment 378704

YMMV.

I think the orifices on my 109s and G250s are all chromed brass, not stainless steel. I guess some of them could be stainless, but I know I've had a few with the chrome pitted.

I think your assumption that the G250V orifice is bottoming out at the same depth may be your problem. All of the issues you are having could be explained by the orifice bottoming out deeper. If they are bottoming out the same I believe the difference in the length of the orifice should be the same as the difference in the depth them bottomed out. If you have a set of digital calipers available it might ease your mind to do the measurements.

I could not get the "short" original orifice to work with the s-wing poppet... you might have a "bad" poppet..

Another "issue" I had was the balance chamber, which at times, despite proper lube, was sticking on the poppet stem. I may have gone back to the original, or another one. Is it free moving on the stem? The test is to put the poppet, seat down on a smooth surface, put the balance chamber on it, and lightly push it down. When you release it, it should come back up on it's own......

It's hard diagnosing over the internet..