What

@Bigbella said...

With due respect to the many contributors to this thread, it would seem that only the OP and one or two others have looked at the schematic before weighing in. We have an apples and oranges problem here.

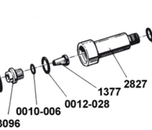

Some of you discussing large torque values are referencing a different part of the regulator than what appears to have loosened in this Signature. Yes, the DIN bolt, or the DIN Housing (as it is called in the Signature) is torqued to 20-30 ft-lb. Yes, this part can loosen if the tank is picked up by the first stage when pressurized.

But it's not the part the OP referred to in post #1: "the bit that takes an allen key and holds the DIN o-ring."

That part, called in the Signature the DIN Retainer, has a completely different function, which is to merely keep the DIN wheel from falling off and to hold the main sealing o-

ring for the tank valve. Its torque is indeed only 80 in-lb, because it is under minimal load. Specifically, it is less than the DIN Housing to keep from inadvertently loosening the critical connection to the reg body when corrosion under the wheel is cleaned, for example.

If I were to guess along with the rest of you regarding a cause, I would suggest that the likely cause is thread lubrication. On page 11, the manual

specifically warns against lubrication except where specified.

Here's what happens: lubrication seems logical, because you know that salt water is going to percolate along the threads and corrode, and you want disassembly to be possible at the next service. Unfortunately, torquing to spec with added lube that was not engineered into the design increases thread load by as much as 150%. And when the lube is inevitably squeezed out from between two adjacent threads over a two-year service interval, that increased axial load may make it impossible to separate the components without damage.

Conversely, given the lack of use of torque wrenches by many shops, AND lubing threads indiscriminantly and excessively, many newly-lubed fittings are very easy to loosen.

It is a sad state of affairs when it was too much trouble for the OP's shop to download the manual (after all, it looked like a Hog!) and follow the directions, instead of going to 15 ft-lb, which is too little for a DIN bolt, and too much for the DIN Retainer.