SlugLife

Contributor

If it's already torqued, I'd probably leave it. I don't think any worse damage will occur that hasn't happened already.Maybe too hard? That came up at my LDS, as well. It's not something I knew to be aware of until now. Always learning. I'd been using Deep 6 Scribbles without any issues for 3 years before upgrading to Signatures in June of this year.

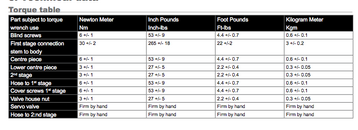

Question on torque: the tech at my LDS ran off and torqued it to 15 ft/lbs (over 2x spec) before I could find the 80 in/lb number in the manual on my phone. He said that it was the standard for HOG regs and that the Deep 6 looked like a HOG. He and the other tech agreed that 80 in/lbs was not enough. My question: should I back it off to spec? Or has the damage been done (hopefully not)?

That is what caused my incident. I followed that advice from others to only make hoses hand-tight, which resulted in a hose coming loose and a pricey 2nd stage lost somewhere on the bottom of the lake. Proper hose-tightness (for anyone reading) is first hand-tight, and then a little more with a tool. I don't know the torque-spec, but it's not that much. Just enough that the hose doesn't come loose.I am amazed that there are people finger tightening their LP hoses! I’ve been diving over 60 years now, and have never had a LP (or HP for that matter) hose come loose. Why? Will, I use a wrench to tighten them down. I see no reason whatsoever to have the LP hoses only finger tight. Is that done so that they can be removed underwater? ‘Doesn’t seem reasonable to me at all.

Now, about the DIN connector; I don’t dive DIN regulators. But it seems that the wheel needs only to be hand tight when putting it onto a tank, as the seal is still an O-ring seal, right? But the wheel attachment to the regulator first stage needs to be tightened to specs. Am I missing something here?

SeaRat

Not in this thread, but I've encountered "hand tight hose" advice before.I don't think anywhere in this thread anyone was saying hoses only finger tight.. maybe I missed it? I was talking about the din wheel being finger tight.

Fwiw, I use wrenches too. Not crazy, just 1/8 snug or so. Enough it can't come loose. Same for plugs.