SIZING

Marine propeller sizes are always specified by diameter and pitch (diameter x pitch) with the diameter dimension specified first. For example: a 15 x 12 propeller has a 15" diameter and a 12" pitch. Normally, these are the only dimensions given in a prop size, which is unfortunate because there are other characteristics of the prop you need to consider when selecting the size. You should always start your search with the diameter and pitch of the prop first then work from there.

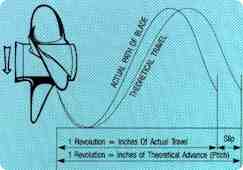

PITCH

Pitch is measured in inches and it is a theoretical measure of how far the propeller should move through the water in one revolution if there was no slippage at all. For example, an 18" pitch prop would move 18" forward in one revolution (provided there was no slippage).

The primary effect of pitch on your performance is the same as the gear-shift in your car. Higher pitch numbers are like the higher gears (4th and 5th) in your car, more speed but less acceleration. Lower pitches are like lower gears (2nd and 3rd): more acceleration but less top speed.

DIAMETER

Diameter is just what you think it is: the diameter of the spinning prop. You can quickly check the diameter by measuring from the center of your prop nut to the tip of one of your prop blades. Double the number you get to get your diameter. Diameter can influence the speed you get, but it has its greatest affect on your acceleration and thrust. Bigger diameter is like adding bigger tires to your car: more traction or more appropriately, less slip. Larger diameters put more load on your motor because they move more water though so don't over do it. A blade moving through water does experience drag . The less blade there is (less diameter), the less the drag will be. Provided your motor and prop produce enough thrust, when you decrease your prop diameter your speed will increase a bit because there is less drag.

NUMBER OF BLADES

AB 200 AB 300 AB 400 How many blades should your prop have? Three blade propellers are the most common, but 4 and even 5 blade props are available. The immediate benefit to increasing your propeller's blade count is increased thrust and a smoother ride (Much like adding more cylinders to your engine). Theoretically, the more blades the lower the efficiency of the propeller. However, increased blade count generally means that each blade no longer has to deal with as much horsepower and consequently the blades can be made a bit thinner which improves their individual efficiency. For example, on a three blade prop running on a 300HP motor, each blade has to handle a 100 hp each. On a 4 blade prop on the same motor, each blade only has to handle 75 HP! This allows the designer to build a prop with a thinner blade without sacrificing stiffness or strength. Unfortunately, the overall efficiency of a multi-bladed propeller is reduced when the blades are forced to run through confused waters - increasing drag. Equally, drag rises to the square (approximately) of speed. Also, a narrow blade, just like a thinner blade passes through the water with less drag. Ideally, therefore, we want a thin section, narrow twin blade, revolving as slowly as possible. Which is just not practical for most boating applications.

CUPPING

Cupping is added to most propeller blades to improve the propeller's bite on the water and decrease slippage. It is most commonly seen on the trailing edge of the blade. Usually the effect of cupping makes the prop perform like a higher pitch propeller, but it does enhance your thrust as well. In addition, cup reduces a prop's tendancy to ventilate or slip. Custom prop builders often use aggressive degrees of cupping to fix slippage problems on large diameter, low pitch props on certain boating applications.

Most props you will encounter are cupped. Most likely, you will only see an uncupped propeller in performance applications. On smaller outboards, which produce most of their power in the upper third of their RPM range, an uncupped prop with a semi-cleaver design often produces better performance. To get maximum performance, it is necessary to get the motor spinning up in this range as quickly as possible. An uncupped prop loads the motor a bit less, allowing the rpm to build more quickly. This enables you to operate your motor in the meat of its powerband where you'll get maximum power. You will notice faster hole-shot, quicker acceleration, and often times, higher top speeds with these semi-cleaver, uncupped style blades. If you are currently running a cupped style propeller and want to improve your overall performance consider trying a semi-cleaver design. Generally, when switching to an uncupped semi-cleaver style prop, you can up the pitch 2 inches and still have better hole-shot, quicker acceleration and often better top speed! Cup can also provide additional bow lift when utilized on the rake line of the prop. Applying cup to the trailing edge of the prop along the pitch line will increase the effective pitch of the propeller. A standard cup will typically result in a decrease of 200 to 400 rpm's. This usually means a decrease in pitch of 1 to 2 inches is required to run a cupped propeller in place of an uncupped wheel.

BLADE RAKE

Blade Rake represents the angle of attachment of the blade to the hub of the propeller. This is not to be confused with the pitch, which is a measure of the twist or screw progression. The amount of rake built into a propeller blade is not something many people consider when buying a new prop, but it can be just what the Dr. ordered in some cases. Rake angle isn't an immediately apparent thing to the untrained eye, but if the propeller blade is cut down the center, it is readily apparent. The biggest benefit of a high rake design is a greater resistance to ventilation. This allows you to trim the outdrive up toward the surface more without the prop ventilating as readily during tight manuevering. You should seriously consider using a high rake propeller if ventilation is a problem for you.

If you have a large boat like a house or deck boat a high rake prop may not be the best choice because it does not produce as much reverse thrust. This may reduce your ability to manuever your vessel at low speeds making your boat more difficult to dock.

Higher rake normally improves performance in ventilating or cavitating situations (high engine elevations and high trim angles). Additionally, higher rake can provide higher bow lift, which will frequently improve speed. Low rake blades are typically used on motors with propellers running fully submerged, typically carrying moderate to heavy loads. The rake angle can either be straight or the average angle of a parabolic curve.

EFFICIENCY

Not many manufacturers quote the efficiency of their propellers and even fewer customers ask. The efficiency of a propeller is defined as the power coming out of a prop divided by the power going in:

Power out

-------------- X 100 For a solar powered boat, efficiency is probably the most important statistic.

Power in

BLADE THICKNESS (thinner blades cut better)

Why is Stainless Steel the first choice for high performance props? A: It is much stronger and far stiffer than aluminum, but that's not the whole answer. The higher strength of stainless means that the blades can be made thinner and that is where the performance benefit comes from: thin blades slice through the water more efficiently than thicker blades. As a result stainless props produce a couple more mph over even the best aluminum designs.

This Design concept is part of the reason our 4-Blade propellers and our uncupped "XB" style 3-Blade propellers outperform our Standard 3-Blade Designs. By incorporating a thinner blade cross-section, those props cut through the water with less resistance. There is a compromise to be made though and that compromise is in durability. The thinner blades are faster, but they are not as durable as our thicker blade designs. If you run up and down a shallow river and hit things frequently, you may be happier sacrificing some performance to run the tougher blades. If you typically run in the ocean with little chance of a strike, you may prefer the added speed of our thinner blades.