The second stage does not know what the air source is, it only knows what the pressure is. If it free flows with that first stage and not with another first stage the IP's are different on the first stages. My guess is that the extra shim raises the pressure well above the 140-145 setpoint.Thanks for the suggestion. I tried it with a couple of other Sherwood second stages that work fine with the IP set to around 140-145 (on other 1st stages) and they do the same thing. I'm not seeing any double-indentations on the valve seat but I'm not ruling it out. I think it was Northeast Scuba that said they are coming out with kits for the older Sherwoods but so far I have not found one. It's the darndest thing but I can't seem to find the model number of the 1st stage. The entire regulator is the 3300.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spring and shims for Sherwood 5100 Brut

- Thread starter Entropyman

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Baseline: I am an LDS and a Sherwood trained service tech. I will do my best to steer you from any misunderstandings or making any poor choices, but I am not in a position to offer anything that is "enabling" you to service your gear yourself.Thanks for the suggestion. I tried it with a couple of other Sherwood second stages that work fine with the IP set to around 140-145 (on other 1st stages) and they do the same thing. I'm not seeing any double-indentations on the valve seat but I'm not ruling it out. I think it was Northeast Scuba that said they are coming out with kits for the older Sherwoods but so far I have not found one. It's the darndest thing but I can't seem to find the model number of the 1st stage. The entire regulator is the 3300.

First, how do you know it is a 3300? Is that printed anywhere, or are you just matching images? If the 1st stage and the 2nd stage have the same serial number, then they are an original pair. If they are different, then you can't determine the exact 1st stage based solely on the 2nd stage - something has moved around. And the SRB3300 is a Magnum II, which is what should be printed on the purge cover.

Assuming you have identified the item correctly, now I can't follow your troubleshooting to date. You say the 2nd stage honks and freeflows with this first stage. Did the other 2nd stages also exhibit problems when attached to this 1st stage? If so, I wonder if your IP gauge is accurate, or if your 1st stage IP is unstable and creeping up. If it is only the original 2nd stage that exhibits problems, then the issue is in the 2nd stage. The service manual lists 8 different possible troubleshooting steps for free flow, 6 of which are 2nd stage related. Then there is also a troubleshooting note each for a noisy 1st and a noisy 2nd, without accompanying freeflow.

I hope that points you in the right direction.

TrimixToo

Contributor

- Messages

- 1,523

- Reaction score

- 1,783

- Location

- New York State...but not for long!

- # of dives

- 200 - 499

Those correct shims are pretty darn thin. It would have to be a very specialized SS washer to not easily exceed the thickness of 3 shims.

My lone Sherwood requires no shims other than the one it came with. The one or two I have that do (Alpha clone first stages from OMS) have pretty thin SS washers in them. If I think about it in a couple of months at rebuild time, I'll measure, but they are certainly less and .050" thick and are probably closer to .030-.040". Finally, these are deco regs. Unless I lose both of them on the same dive, it's only inconvenient. I always dive with an executable lost gas plan...

Without a calibrated spring tester, it's hard to tell what's going on, but at least one of the OMS firsts (from the old "workhorse" series) has had a low IP since new, essentially. I want my seconds to be interchangeable, so just adjusting the second to work with the lower IP, which would make it breathe just fine, didn't help achieve that goal.

I have yet to see a spring tester on the bench at an dive shop, BTW, but they are routinely used in engine rebuilding. Automotive valve springs are routinely shimmed to compensate for both tension and installed valve height as long as they have enough free length so they won't stack solid, and they are stressed a *lot* more than first stage springs in regs.

Not all Sherwood 1st stage shims are created equal. Some early versions have the adjusting washer on the other side of the body, NOT in contact with the spring. I don't know if that was a stainless steel part or not, but I suspect it was, as the added force was transferred to the spring via 3 adjusting pins using just 3 small points of contact. So please don't anyone offer or accept advice based on the assumption everyone else's Sherwood 1st is the same as yours, using the same materials with the same dimensions. There are a lot of generations of production and design out there. Some 1st/2nd combinations are also designed to operate at a lower IP.

@TrimixToo I'm not sure what your point is on 1st stage springs. Feels like you are saying you don't believe they ever wear out?

However it happens, 1st stage springs do wear out over time and replacement is always (almost always?) listed as a troubleshooting option. Replacing a HP spring has been the necessary solution for me, after first trying all cheaper troubleshooting options, at least twice this year on old units from two different brands. I have never seen anyone using or even offering for sale a spring tester for regulator service. For that matter, even if we did, we don't have specs for the right or the wrong of any spring. The simple and effective method is to just try a new spring and see if it solves the problem. I suspect that costs just a bit less than a spring tester. Sometimes you can even see a difference in height between the worn spring and the new spring if you look closely enough. The worn one with low IP will be a little shorter.

@TrimixToo I'm not sure what your point is on 1st stage springs. Feels like you are saying you don't believe they ever wear out?

However it happens, 1st stage springs do wear out over time and replacement is always (almost always?) listed as a troubleshooting option. Replacing a HP spring has been the necessary solution for me, after first trying all cheaper troubleshooting options, at least twice this year on old units from two different brands. I have never seen anyone using or even offering for sale a spring tester for regulator service. For that matter, even if we did, we don't have specs for the right or the wrong of any spring. The simple and effective method is to just try a new spring and see if it solves the problem. I suspect that costs just a bit less than a spring tester. Sometimes you can even see a difference in height between the worn spring and the new spring if you look closely enough. The worn one with low IP will be a little shorter.

Ghetto Diver

Contributor

I have tried adding washers (temporarily) to determine just how much thickness I need. Whenever I add enough to exceed about 125 psi the second stage goes bonkers and makes honking noises and free-flows. Does this mean I have a bad O-ring or valve seat somewhere? It seems to work fine at 125 psi, but, of course, that is way below the specs so I'm not going to dive with it.

What's the thickness of the washers? One at a time?

I have done this with a ss washer that I stoned down to get the desired effect. I suspect the washers you used are off the shelf (not shims) and are rather thick.

I have enough complete Sherwoods and parts that I changed springs to get the higher ip I wanted without shims.

I used plastic shims that I picked up at the hardware store that worked well too.

What's with the herp derp in this thread anyway...some posters would have a fit with some of my franken-brut creations.

TrimixToo

Contributor

- Messages

- 1,523

- Reaction score

- 1,783

- Location

- New York State...but not for long!

- # of dives

- 200 - 499

Not all Sherwood 1st stage shims are created equal. Some early versions have the adjusting washer on the other side of the body, NOT in contact with the spring. I don't know if that was a stainless steel part or not, but I suspect it was, as the added force was transferred to the spring via 3 adjusting pins using just 3 small points of contact. So please don't anyone offer or accept advice based on the assumption everyone else's Sherwood 1st is the same as yours, using the same materials with the same dimensions. There are a lot of generations of production and design out there. Some 1st/2nd combinations are also designed to operate at a lower IP.

@TrimixToo I'm not sure what your point is on 1st stage springs. Feels like you are saying you don't believe they ever wear out?

However it happens, 1st stage springs do wear out over time and replacement is always (almost always?) listed as a troubleshooting option. Replacing a HP spring has been the necessary solution for me, after first trying all cheaper troubleshooting options, at least twice this year on old units from two different brands. I have never seen anyone using or even offering for sale a spring tester for regulator service. For that matter, even if we did, we don't have specs for the right or the wrong of any spring. The simple and effective method is to just try a new spring and see if it solves the problem. I suspect that costs just a bit less than a spring tester. Sometimes you can even see a difference in height between the worn spring and the new spring if you look closely enough. The worn one with low IP will be a little shorter.

Sorry I wasn't clear. Springs do fail. Some lose spring rate and/or free length ("sag"), and some break. A good spring should, however, last a really long time as long as the thing it's installed in keeps reasonably within its elastic limits. Automotive valve springs operate in a much harsher environment and are more highly stressed and most easily last more than 250K miles. But to *know* a spring is in spec and that there is not some other problem, you need a spring tester. I have also never seen a spring tester used on regulator springs, nor specs for the springs themselves. This technology apparently has bypassed the scuba market (grin), likely because good spring testers are not cheap ($500 or so and up).

The free length might or might not change when the spring goes out of spec, but IIRC, free length, installed length, and spring rate are the three things of interest. You can measure the free length and if you keep a notebook you can find springs that are shorter than usual. *If* we used spring testers (I sure haven't got one), you could see whether the rate was still OK and choose to shim, or whether the rate was not OK irrespective of the length so you would know it had to be replaced.

All this is theoretical for scuba since nobody publishes the specs.

My opinion (I am not an engineer or certified tech) is that since the range of motion for most first stages springs is narrow, even an out of spec length spring that does not have internal problems can be shimmed to set the IP without any immediate problems, to a point. So long as the IP remains stable, and one does not shim outside the realm of reason, I *think* this is likely OK.

I'll add that I don't see anything wrong the current industry practice. The range of possibilities for something that won't hold the right IP is pretty narrow.

Sherwood does specify maximum number of shims to use before changing a spring. Varies by age of design. Most I have seen is 3, and they are THIN!

OP

Entropyman

Registered

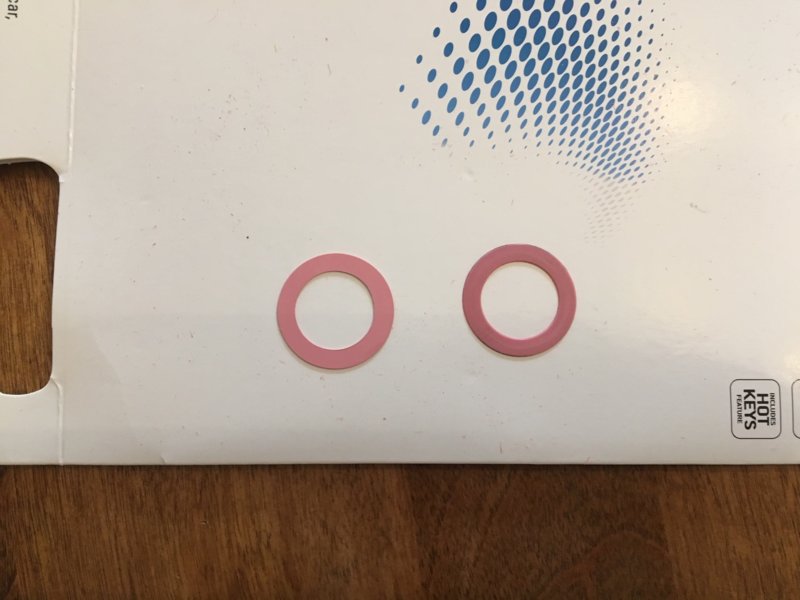

The plastic shims I ordered from McMaster-Carr came in last week. Thickness and ID were good for my application but OD was about .06" to big. I mounted all 10 of the shims into a modified hole saw arbor, put them in a drill press, and sanded them down to the 0.940" that I needed. After some cleanup, they fit into the first stage very well. The shim on the right is the one that came out of the 1st stage, the one on the left is the one I modified. I have not checked the IP yet.

spoolin01

Contributor

Those shims will fit on the body side of the spring without modification.The plastic shims I ordered from McMaster-Carr came in last week. Thickness and ID were good for my application but OD was about .06" to big. I mounted all 10 of the shims into a modified hole saw arbor, put them in a drill press, and sanded them down to the 0.940" that I needed. After some cleanup, they fit into the first stage very well. The shim on the right is the one that came out of the 1st stage, the one on the left is the one I modified. I have not checked the IP yet. View attachment 492202

View attachment 492203

Prior to the 5000 series there was no model indication on the 1st stage itself, and the 1st/2nd set was given a model designation based primarily on which 2nd stage was used, from what I can tell from the service documentation. However the 1st stages did have a unique model designation indicated in the documentation (and in the body sub-unit P/N itself), which so far as I can tell can be determined from appearance (ribs and cap). Starting with the 5000 series, the "set" model is etched on the 1st stage body I believe. Interestingly, there is some sharing of body P/Ns from the 5000 to the 7000 series - I gather mostly the number etching was changed.First, how do you know it is a 3300? Is that printed anywhere, or are you just matching images? If the 1st stage and the 2nd stage have the same serial number, then they are an original pair. If they are different, then you can't determine the exact 1st stage based solely on the 2nd stage - something has moved around.

Those pin models are *really* old. Aside from the 3601 (used in the SRB3600 Maximus, SRB3700 Oasis 2, and SRB3900 Blizzard - which used a two-piece adjustably threaded body for IP adjustment), all the "ribbed" models (and a few prior to that) appear to have used shims. The 5000/7000 series appear to be the same models internally. Earlier ones used smaller shims. Haven't seen a 9000 series in person.Not all Sherwood 1st stage shims are created equal. Some early versions have the adjusting washer on the other side of the body, NOT in contact with the spring. I don't know if that was a stainless steel part or not, but I suspect it was, as the added force was transferred to the spring via 3 adjusting pins using just 3 small points of contact.

the problem with the3900 2 piece is it it is easily moved by the person attaching the reg , it holds put by a set screw that bits into the body , its round and tends to slip after awhile ...so I invented a titanium set screw that's pointed and really sticks in to keep it in place

Similar threads

- Replies

- 3

- Views

- 314

- Replies

- 12

- Views

- 913

- Replies

- 14

- Views

- 2,139