first thanks a bunch for this in depth explanation -- Amateur you say  , I would take your word over most "experts"

, I would take your word over most "experts"

Anyway this is a "let's see how far we can take it" project -- nothing to lose except some fun time gutting regs and trying to Frankestein them back

I have a couple of D service kits / poppets -- I can start by getting one out of storage once the AIR arrrives, and start debugging it in hopes of understanding it

Anyway this is a "let's see how far we can take it" project -- nothing to lose except some fun time gutting regs and trying to Frankestein them back

for sure I will start with that AIR1, less chrome to hurt and parts to looseA good approach might be starting with a service of the Air1 before moving the the pilot conversion. The experience of getting familiar with the Air1 parts and tuning will help on the pilot project.

I have a couple of D service kits / poppets -- I can start by getting one out of storage once the AIR arrrives, and start debugging it in hopes of understanding it

are they around the same length? can that be ground off maybe? or is that not worth it?The D levers will not work, they lack the flat section needed to fit the Air1 diaphragm rod.

funny I was able to find a few Pilots, but only one single AIR 1 -- I will keep a look outthe simplest approach for a conversion may end up being using a cheap Air1 to as parts donor

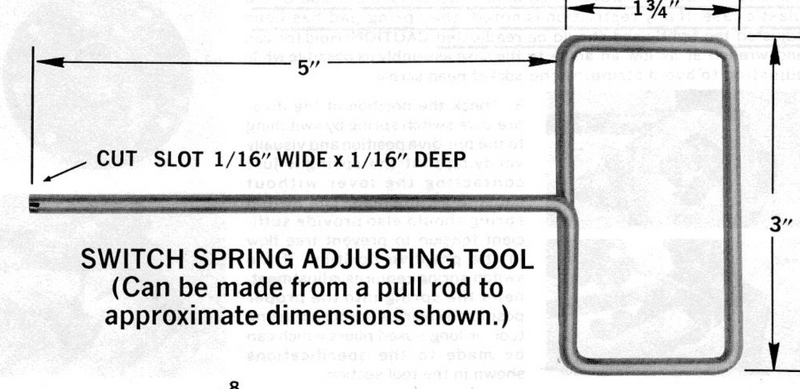

I got one already, but going through the service manual you shared, I was more worried about this tool -- how necessary is it?an adjustable pin spanner with 4mm pins.