Good day all, finally getting around to the rebuild. I have a few issues / questions. Maybe

@iain/hsm can chime in.

1st issue;

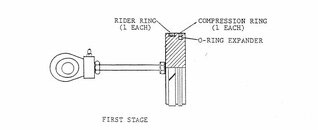

The 1st stage piston states there is supposed to be a rider ring, a compression ring, and an o ring expander. This is how mine came apart. The diagram shows the 3 rings. On my piston there is a groove below the rider ring. I'm not sure if this is supposed to get another o ring expander or if it just stays empty? In the picture that I took I have it setup the way it is in the diagram, but I am questioning what that other groove is for?

2nd issue;

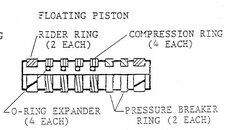

On the 3rd stage piston there are grooves for the "pressure breaker rings". On my piston the gap measures .072 amd .069 (as seen in the picture). The old pressure breaker rings measure .069, the new ones measure .0715-

.075. I can get them to fit in the groove that measures .072 but there's no way they'll fit in the groove that measures .069. I'm thinking maybe these are out of tolerance from the manufacturer? Maybe the piston is out of tolerance?

Not sure if I could lightly sand these down to fit or what the protocol is?

I could not find anywhere in any literature what any of these are supposed to measure.

If it matters old rings thickness measure .069, .069, .069, .0695

New rings thickness measure .0715, .0715, .072 and

one came in at .075!

(note see DM, too)

(note see DM, too)