First, I'm good for a dozen nuts to start.

But... don't shoot the messenger.

I think we need to decide whether you want this nut to be just a G250 nut, or have wider application.

As you know the G250V, G260, and R- and S-series have that little land for a sealing o-ring between the barrel nut and the B-nut for the hose. The G250 does not.

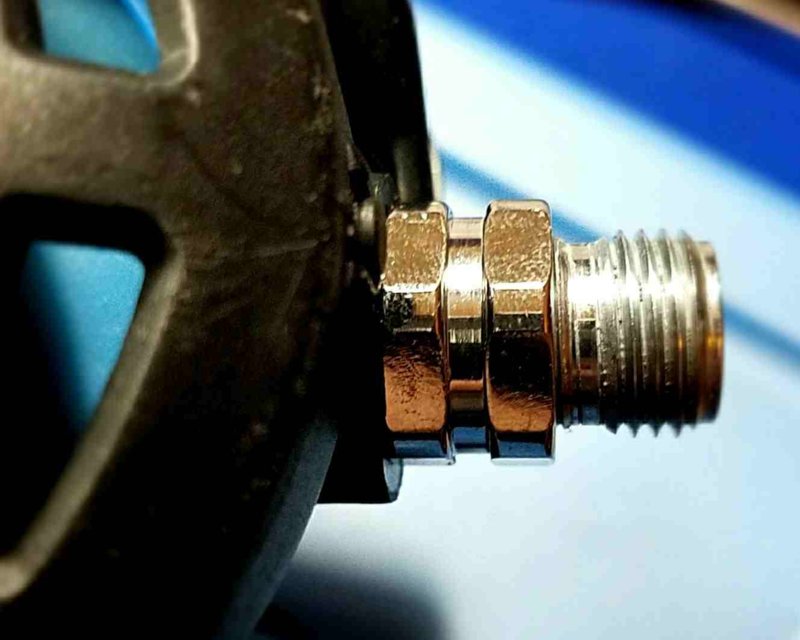

As you can see below, the Atomic .437" nut fits fine on an S-series spindle, and the tall nut fits fine on a G260 barrel:

But the distance from the reg body to the land is different between the two regs.

G250V & G260 have longer run, while R- and S-series have shorter run.

That means, if we use an Atomic nut, or an even shorter 0.425" nut, threads will protrude from the nut before the land.

G260:

G250V:

But... don't shoot the messenger.

I think we need to decide whether you want this nut to be just a G250 nut, or have wider application.

As you know the G250V, G260, and R- and S-series have that little land for a sealing o-ring between the barrel nut and the B-nut for the hose. The G250 does not.

As you can see below, the Atomic .437" nut fits fine on an S-series spindle, and the tall nut fits fine on a G260 barrel:

But the distance from the reg body to the land is different between the two regs.

G250V & G260 have longer run, while R- and S-series have shorter run.

That means, if we use an Atomic nut, or an even shorter 0.425" nut, threads will protrude from the nut before the land.

G260:

G250V:

Last edited: