Water Boy76

Contributor

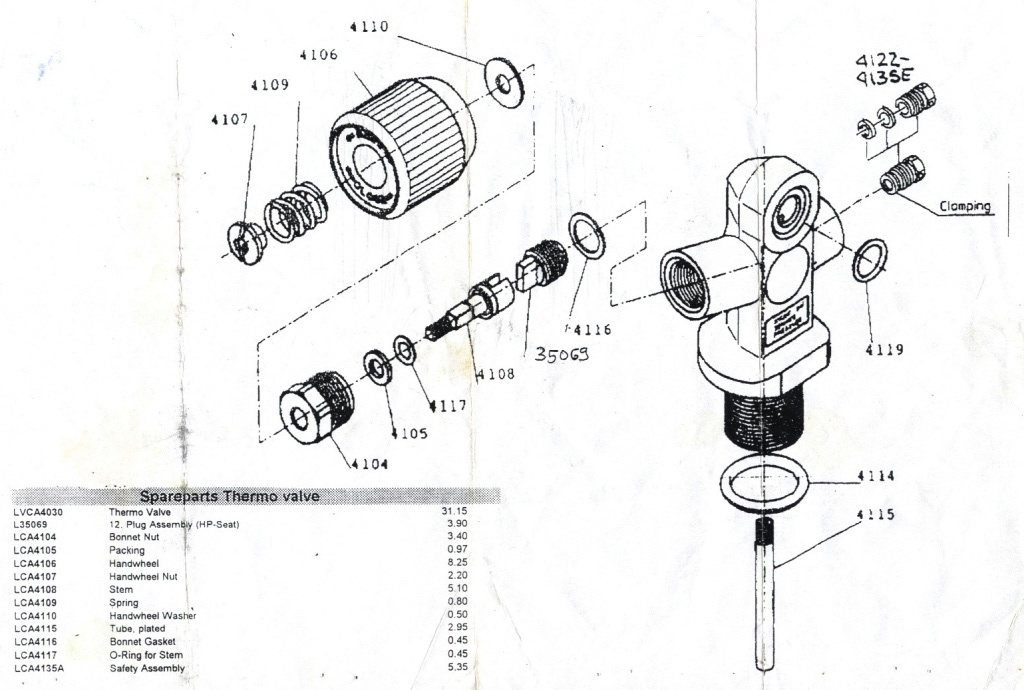

I have a slow leak in one of my valves. It's loosing around 1,000 PSI a week. I've sprayed the neck with soapy water and don't see any bubbles. I'm assuming it's a leaking O ring somewhere else.

Q: How difficult is it to take valve apart, clean and put back together. There can't be too much to it - right? Of course I can take to the shop but a part of me want to do it myself to learn how it's done.

Are there any tricks I should know about? Assume I know nothing, because I do know nothing. Also, is there a place I can order the O-rings or kits?

FWIW it's a Faber Pro Valve that come's standard with the steel tanks. The nut holding the on/off knob looks a bit strange?

Thx.

Q: How difficult is it to take valve apart, clean and put back together. There can't be too much to it - right? Of course I can take to the shop but a part of me want to do it myself to learn how it's done.

Are there any tricks I should know about? Assume I know nothing, because I do know nothing. Also, is there a place I can order the O-rings or kits?

FWIW it's a Faber Pro Valve that come's standard with the steel tanks. The nut holding the on/off knob looks a bit strange?

Thx.