How sure are you that the SLA failures had all passed hydro?I apologise if this post is TL;DR

Firstly The Hydro/VIP method is proven to work, by that I mean very few cylinders fail in service while having a current Hydro/Vis

Is it perfect and a 100% guarantee that a cylinder has no defects? No.

You also have the problem at the local level where employees at the LDS can have poor of minimal training and knowledge. The classic case of not distinguishing the differences between Steel and Ali cylinders with regard to their standards and criteria. People read or listen to what they believe is valid information and make decisions based upon it. For that come procedures and rules, often based upon the foundation of falsehoods.

Back to Hydro/Vis.

Most cylinders are condemned by Vis, its actually the primary method. Hydro as you know only tests that the parent material expands and contracts within limits and the cylinder holds pressure. A cylinder with out of limits pitting or cracking (to a degree) will still pass hydro

The SLA failures had all passed hydro, however their defects should have been picked up on Vis (because of the slow growth nature of the defect, and the fact that it could get to a significant size before going critical.

I come from a materials test background. Visual inspection is much maligned (given it uses no fancy equipment) but in fact it requires much diligence and a degree of experience to carry out correctly. Fortunately most people err on the side of caution or seek out a second opinion.

However there are numerous example within the inspection community of clearly apparent defects being missed. Improperly/untrained or lackadaisical inspectors excepted, sometime we "see" what we expect to see, rather than what is before our eyes.

A classic case is proof reading where we see what we thought we've typed/written, rather than what we actually have.

Finally teh FSO (fill station operator) needs to satisfy themselves that the cylinder to be filled not only has valid in date inspections but that they (the FSO ) has confidence in the inspectors knowledge, training and experience.

With Hydro this is easy, since [I assume] in the US its via DOT approved/certified shops, whereas with Vis, not so much given anyone can create and print their own sticker. While I understand the desire in the litigious environment of the US, people want teh protection of anonymity, in reality if you want an robust practice, then the VIP stickers need to have an ident allowing that inspection to be traced to an inspector allowing their certification etc to be checked.

Being a qualified inspector means you have to have the courage of your convictions and accept public responsibility for your pass decisions during the validity of the inspection interval.

The opinion of the FSO is a circular and much debated argument so I'll go no further with it.

Old tanks.

Certainly the statistics back up that there are few failures (although there is no data to show what percentage of tanks remain in service)

People often cite the fact that manufacturers carry out high numbers of pressure tests on samples, together with lack of real world failures and definitive evidence that old cylinders are safe. And yes that argument has validity, however while the risk of failure is low, it's not impossible.

Over the years I've seen lots of in service failures not predicted by the physical testing nor the stress models. While component testing protocols are good, they simply cannot replicate all the variables that a real life component experiences. We just have to accept we get failures that are as low as reasonably practicable.

The FSO/LDS is really left with a few choices:

1. Blindly accept that all inspections have been carried out correctly by appropriately trained and experienced persons.

2. Trust those persons known to them of who have satisfied the shop they they are experienced and competent, for all others insist of their own Vis

3. Insist they only fill cylinders they've inspected themselves thus taking full responsibility.

4 Buy an explosion proof tank and roll the dice or put in place some arbitrary rules with satisfy their own risk factor

Where as divers have the following choices

1. Accept and abide by the Shops rules

2. Go elsewhere.

3. Buy their own compressor

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old steels denied fills due to store "policy"

- Thread starter Ana

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Just curious, you seem to be conflating the safety record of tanks that undergo regular hydro and viz ("the statistics back up that there are few failures") with your own experiences as a materials inspector (type of materials undisclosed).

No, you misunderstand. I'm merely pointing out, that the Vis/Hydro inspection process is indeed satisfactory, and as you rightly say, the reported incidents meet the threshold of ALARP (As Low As Reasonably Possible) it cannot be 100% perfect, and certainly there is the possibility (however remote) for the process to fail (again SLA failures while within inspection validity)

As for my experience, I've been involved in Aerospace, Defence and Industrial. so the usual suspects of Metallics and their alloys inc some strange stuff as well as carbon fibre.

Again, people believe Hydro is a better inspect than Vis - it serves a different purpose, and as previously stated, in actual fact Vis is a better inspection if properly and diligently carried out.

When it comes to old tanks, while the Statistics are still valid, the risk does become greater. Yes a new cylinder is tested to 50,000? cycles which can validate the design of a component in ideal conditions, and sure cylinders are over engineered to help compensate for unforeseen events in the life of a cylinder. Yes the loads (not stress) is highly predictable and very simple. No argument.

However with age so increases the risk. I suggest there is only a relatively small sample of old Steel scuba cylinders around currently because wet fills etc were more common back in the day as time passes there will be more steel cylinders out there and the statistics will change accordingly

Regarding service life, ask a cylinder manufacturer to put a definitive life in writing on them (they won't because they can't).

As stated previously it's the shops responsibility to determine if the cylinder is safe to fill. All they have to go on is whether the cylinder is in date, and whether they trust the inspection and their risk level.

In a perfect world you'd eddy current test each cylinder annually on an automated rig (like an aircraft wheel tester) which gives a pass fail, and failures are subjected to inspection by a trained inspector. But the market wouldn't sustain that and of course the current statistics point to not needing it

I can't be sure that all had passed hydro, its long ago and internet docs are scarce. I'd love to see copies of the original failure analysis as they make really interesting readingHow sure are you that the SLA failures had all passed hydro?

Some had.

SLA is really slow growing, and cracks have growth striations (much like tree rings) so you can measure growth speed over time

It is a certainty that the defects should have been picked up on Vis - probably multiple vis inspections, and very likely the pre/post hydro vis

What is SLA in your posts? I am familiar with sustained load cracking on the "old" aluminum alloy, but have not heard your term.I can't be sure that all had passed hydro, its long ago and internet docs are scarce. I'd love to see copies of the original failure analysis as they make really interesting reading

Some had.

SLA is really slow growing, and cracks have growth striations (much like tree rings) so you can measure growth speed over time

It is a certainty that the defects should have been picked up on Vis - probably multiple vis inspections, and very likely the pre/post hydro vis

HalcyonDaze

Contributor

As stated previously it's the shops responsibility to determine if the cylinder is safe to fill. All they have to go on is whether the cylinder is in date, and whether they trust the inspection and their risk level.

In a perfect world you'd eddy current test each cylinder annually on an automated rig (like an aircraft wheel tester) which gives a pass fail, and failures are subjected to inspection by a trained inspector. But the market wouldn't sustain that and of course the current statistics point to not needing it

And I think that's the rub in this. At what level is it reasonable to feel safe filling a cylinder? You're never going to get to 100%, even with one you've hydro'd and VIP'd personally, and drawing an arbitrary age line simply on gut feeling is not going to achieve that either.

Unlikely that it will be undoing for Force-E. They have had this policy for about 20 years now and they are still doing fine.

Going back to the OP and my first post here, I actually went and checked on my LP tanks last night - the ones currently sitting against my living room wall with 1000 psi more gas in them than the stamp - and they both have 1995 born-on stamps. Which means according to some posters in here, I should scrap them ... which is funny, because while Force-E Riviera ran me through that whole production of taking the valves off and checking the o-rings/lube twice in 2017, they filled my tanks right up afterwards despite presumably being two years past their arbitrary cutoff date.

Scuba Lawyer

Contributor

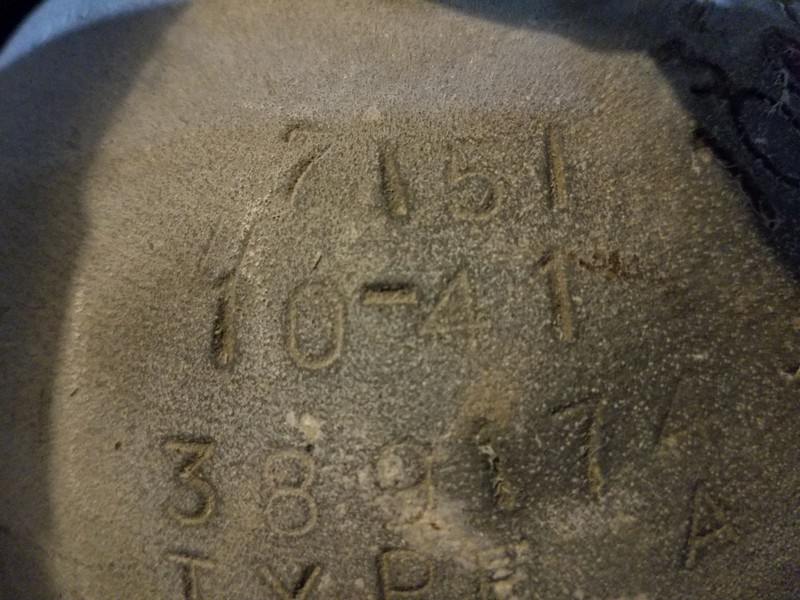

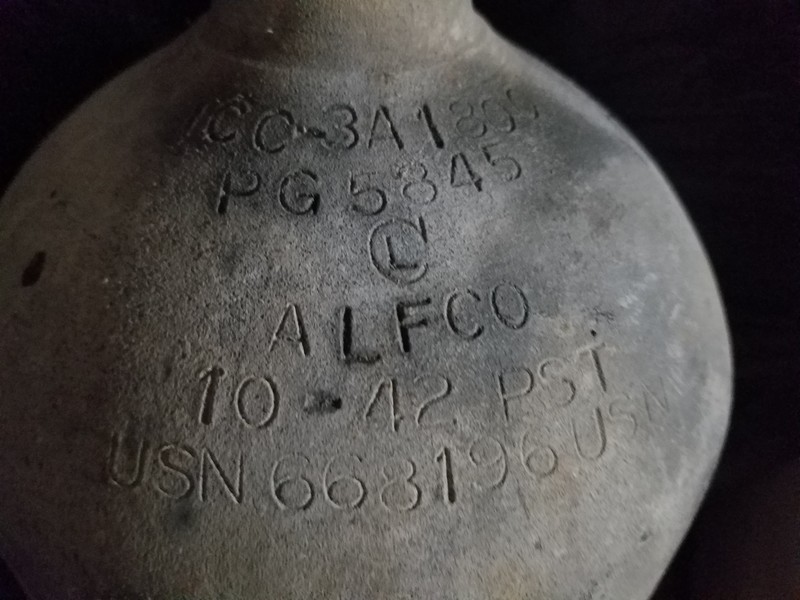

So, where is this Florida dive shop I should be getting my steel twin 38's with original hydro dates of 1941 and 1942, respectively, filled? Just because one if them was manufactured pre- Pearl Harbor doesn't make 'em unfillable.

HalcyonDaze

Contributor

So, where is this Florida dive shop I should be getting my steel twin 38's with original hydro dates of 1941 and 1942, respectively, filled? Just because one if them was manufactured pre- Pearl Harbor doesn't make 'em unfillable.

View attachment 570458

View attachment 570459

Scuba tanks that pre-date Cousteau's Aqualung, eh? Do they still pass hydro and vis?

Scuba Lawyer

Contributor

Scuba tanks that pre-date Cousteau's Aqualung, eh? Do they still pass hydro and vis?

They are repurposed USN tanks that I was told were somehow involved in the system that sent or retrieved the trap wire across the decks of aircraft carriers. Many of these tanks were made into dive tanks in the 1950's using reducer bushings and npt valve threads. One just passed hydro but, sadly, the newer one did not. VIP-wise they are pristine inside. Need to find an 80 year old replacement.

My term embarrassingly is a function of auto correct not noticed because of the influence of medical drugs for a tooth infection. Please mentally replace SLA for SLC while I hang my head in shame.What is SLA in your posts? I am familiar with sustained load cracking on the "old" aluminum alloy, but have not heard your term.

And I think that's the rub in this. At what level is it reasonable to feel safe filling a cylinder? You're never going to get to 100%, even with one you've hydro'd and VIP'd personally, and drawing an arbitrary age line simply on gut feeling is not going to achieve that either.

Applying arbitrary limits based on gut feeling is never helpful, you're correct. But those that do would logically draw a line past a date where the number of tanks above an age drop off in popularity

Equally cylinders are so in expensive that apart from sentimentality there is little justification in requiring that an old cylinder be allowed to continue in service. Keeping a cylinder for 20 years means its cost is roughly $20 per year (an unpopular view I'll accept)

I have 30 steels. Keeping them for 40 years brings the cost to roughly $10/year. If I can sell them when I am finally done with them it makes the cost lower.My term embarrassingly is a function of auto correct not noticed because of the influence of medical drugs for a tooth infection. Please mentally replace SLA for SLC while I hang my head in shame.

Applying arbitrary limits based on gut feeling is never helpful, you're correct. But those that do would logically draw a line past a date where the number of tanks above an age drop off in popularity

Equally cylinders are so in expensive that apart from sentimentality there is little justification in requiring that an old cylinder be allowed to continue in service. Keeping a cylinder for 20 years means its cost is roughly $20 per year (an unpopular view I'll accept)

Similar threads

- Replies

- 13

- Views

- 1,330

- Replies

- 3

- Views

- 206

- Replies

- 9

- Views

- 528

- Replies

- 54

- Views

- 4,970