fweber

Contributor

Very good...

smart as_ ...

Sorry,..... I wasn't intending to be an ***......it just comes naturely.

Luis, I unfortunately lost a long typed response to your post 12 from yesterday.

Reader Digest Version:

Essentially, we agree on most points. We should be careful to seperate the discussion of the characteristics and concerns with regard to AL vs ST cylinders.

AL pose a real catastrophic issue beyond hydro, due to the fact that hydro does not detect neck cracks.

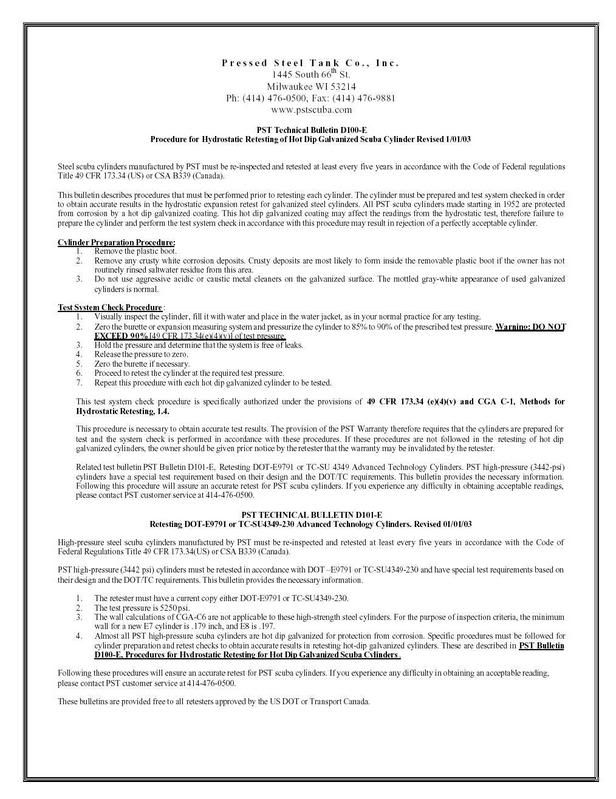

Steel tanks don't all require "roundingout/leak checks". 3AA cylinders can be tested all day with no need for such. It's PST's E series that cause headaches. And how exactly does a manufacturer get authorized to "require" that a "leak check" gets used as a modification to a DOT procedure?

Sorry for the breavity, but here comes the boss.