Custom Scuba Tools Yoke Retainer Wrench

Have you ever wanted or needed just a simple tool designed specifically for one task? Earlier this year I asked Herman for a couple of custom made tools. As always, he delivered a better made and better designed set of tools than I imagined. Today, I’m posting a review of Custom Scuba Tools Yoke Retainer Wrench. Later I’ll review a different item.

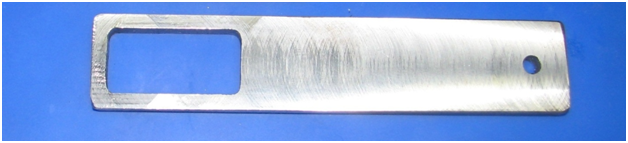

The Yoke Retainer Wrench is a variation of an old ScubaPro tool I have from the days when I worked in a dive shop. Basically it’s a flat piece of metal with a rectangular hole cut into it which slips over the yoke and onto the yoke retainer. The original is very easy to use, but being made of thin aluminum it's not ideal. This is especially true for tough nuts to crack as it can damage over torqued or corroded-in-place retainers. Because of the length, the old gal does not pack well as part of a diver’s travel tool kit.

Original ScubaPro tool

Well, say hello to my new little friend!

CST YOKE RETAINER WRENCH

Side by side

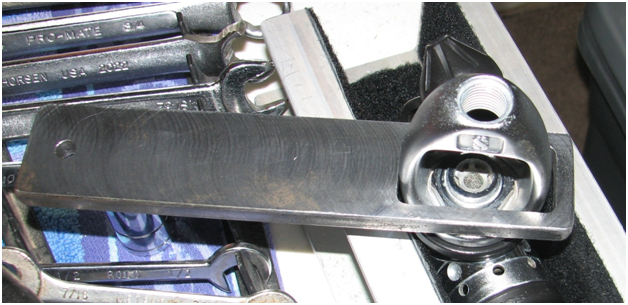

CST wrench in action

Notice the steel construction. At 0.30 inches this bad boy is over twice the thickness of the wimpy SP wrench and fits over the entire thickness of the retainer flats. The perfectly machined slot will not open up after a couple of centuries of use like its aluminum predecessor. Machining the slot near one end of the wrench rather than in the middle allows for an overall shorter tool which makes it easier to carry in your tool kit. Likewise it’s cheaper to ship and keeps the overall cost of the tool down. This design does have a slight drawback over the SP tool. One cannot bear down on both sides of the wrench to loosen a difficult retainer, so extra care and proper positioning of the first stage is important. Having said that, I tested it to make sure I could apply over 300 inch pounds of torque. (The most current drawing I have shows the SP retainer torque to be 266 inch pounds <30 nm>.) I also torqued a retainer on an old regulator to 400 inch pounds to ensure I could remove it without the help of a cheater bar.

This wrench is a very reasonably priced alternative to an expensive, specially modified 1 inch socket. Not to mention if one adds an extension and ratchet (or breaker bar.) It also saves rebuild time by not having to place a socket in the yoke, then an extension and handle. Think about the shop tech that might have to break down several regulators around the same time. He or she could loosen a dozen yoke retainers with this tool in the time it takes to set up the socket, extension, and handle. Of course I expect a shop tech to use a torque wrench when installing the retainer-but for an owner/DIY type who knows how much ~ 266 inch pounds is, it’s perfect. Who else might benefit by owning this tool? If one is often changing between yoke and DIN it would be advantageous to have in a travel kit. Recently, there was a thread re a yoke retainer that came loose on a dive due to being under torque or more likely someone was handling the weight of the tank by using the regulator body for a grip. If the OP had the tools handy, it would have been problem solved on surface interval.

Save time, save money-get one!

Contact @herman the owner/manager/janitor of Custom Scuba Tools for price and shipping.

Have you ever wanted or needed just a simple tool designed specifically for one task? Earlier this year I asked Herman for a couple of custom made tools. As always, he delivered a better made and better designed set of tools than I imagined. Today, I’m posting a review of Custom Scuba Tools Yoke Retainer Wrench. Later I’ll review a different item.

The Yoke Retainer Wrench is a variation of an old ScubaPro tool I have from the days when I worked in a dive shop. Basically it’s a flat piece of metal with a rectangular hole cut into it which slips over the yoke and onto the yoke retainer. The original is very easy to use, but being made of thin aluminum it's not ideal. This is especially true for tough nuts to crack as it can damage over torqued or corroded-in-place retainers. Because of the length, the old gal does not pack well as part of a diver’s travel tool kit.

Original ScubaPro tool

Well, say hello to my new little friend!

CST YOKE RETAINER WRENCH

Side by side

CST wrench in action

Notice the steel construction. At 0.30 inches this bad boy is over twice the thickness of the wimpy SP wrench and fits over the entire thickness of the retainer flats. The perfectly machined slot will not open up after a couple of centuries of use like its aluminum predecessor. Machining the slot near one end of the wrench rather than in the middle allows for an overall shorter tool which makes it easier to carry in your tool kit. Likewise it’s cheaper to ship and keeps the overall cost of the tool down. This design does have a slight drawback over the SP tool. One cannot bear down on both sides of the wrench to loosen a difficult retainer, so extra care and proper positioning of the first stage is important. Having said that, I tested it to make sure I could apply over 300 inch pounds of torque. (The most current drawing I have shows the SP retainer torque to be 266 inch pounds <30 nm>.) I also torqued a retainer on an old regulator to 400 inch pounds to ensure I could remove it without the help of a cheater bar.

This wrench is a very reasonably priced alternative to an expensive, specially modified 1 inch socket. Not to mention if one adds an extension and ratchet (or breaker bar.) It also saves rebuild time by not having to place a socket in the yoke, then an extension and handle. Think about the shop tech that might have to break down several regulators around the same time. He or she could loosen a dozen yoke retainers with this tool in the time it takes to set up the socket, extension, and handle. Of course I expect a shop tech to use a torque wrench when installing the retainer-but for an owner/DIY type who knows how much ~ 266 inch pounds is, it’s perfect. Who else might benefit by owning this tool? If one is often changing between yoke and DIN it would be advantageous to have in a travel kit. Recently, there was a thread re a yoke retainer that came loose on a dive due to being under torque or more likely someone was handling the weight of the tank by using the regulator body for a grip. If the OP had the tools handy, it would have been problem solved on surface interval.

Save time, save money-get one!

Contact @herman the owner/manager/janitor of Custom Scuba Tools for price and shipping.