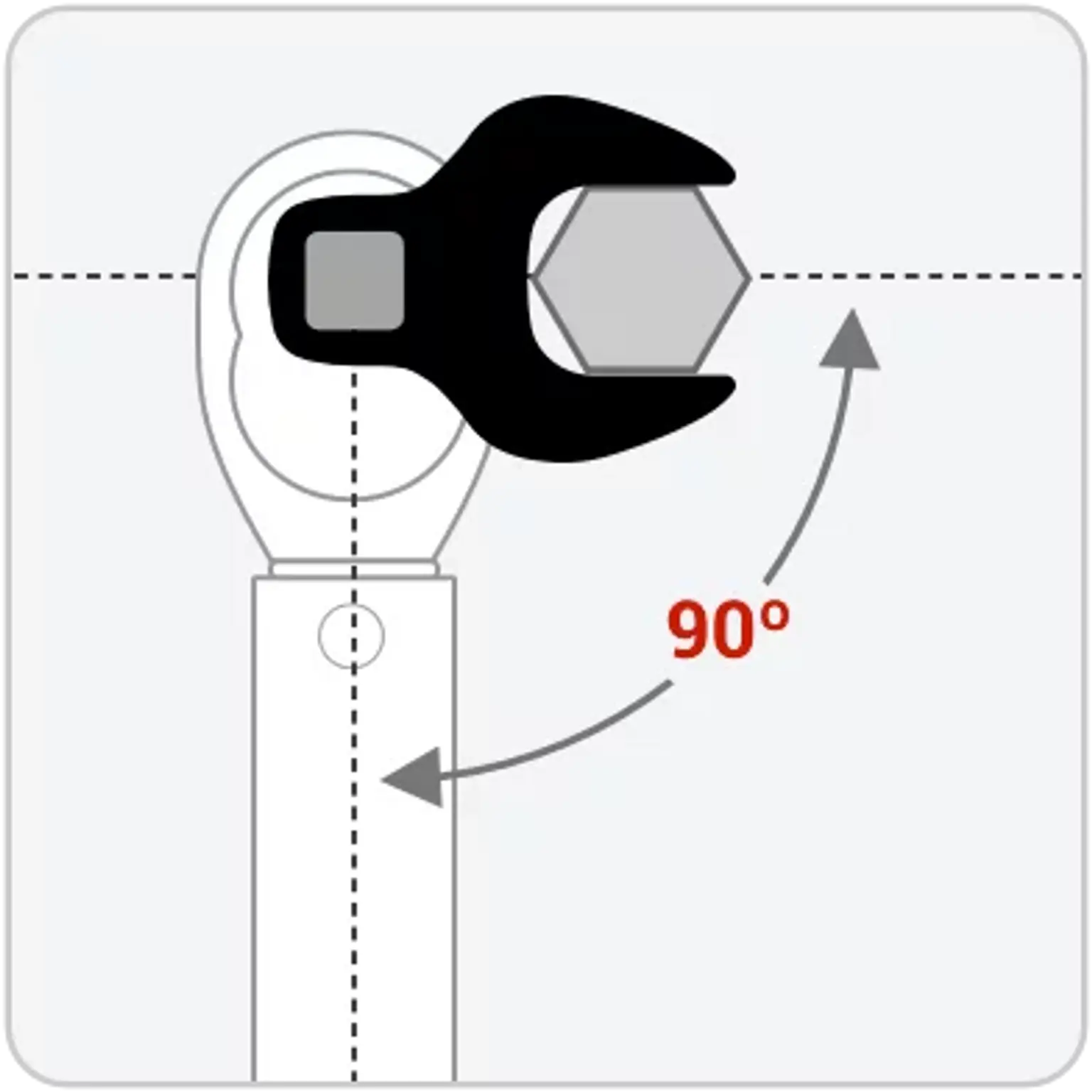

Anyone have any ideas how I can torque the SKF lock nuts?

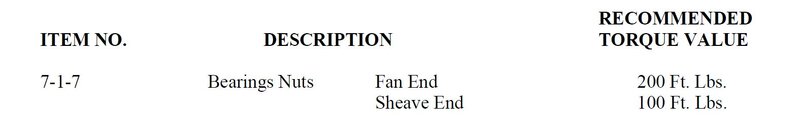

One side is torqued to 100lb, the other side is 200lb. I'm pretty sure I have a spanner in the shop.. but not sure how I'd torque to spec. Obviously I don't have the special HSM tool, lol.

One side is torqued to 100lb, the other side is 200lb. I'm pretty sure I have a spanner in the shop.. but not sure how I'd torque to spec. Obviously I don't have the special HSM tool, lol.