You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Setting Up Cascade

- Thread starter rob.mwpropane

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 20,805

- Reaction score

- 15,537

- # of dives

- I'm a Fish!

Can anyone link / give me a quick rundown of flexible hose vs ss tubing and compression fittings? I believe I have the right tool, and I "think" it would be cheaper than getting a bunch of hoses made up. Thoughts? I know it would be more time consuming to setup, but I'm used to furling. I don't think I would need the valves, I'll just use the valves on the tanks. If I could find inexpensive valves I might do it, but they get pricey fast.

Does anyone know offhand the reason to install "loops" in the tubing?

Something like this;

flex hoses are convenient, but much more expensive, especially for long runs and they are not a DIY solution. You can DIY the tubes pretty easily with hand tools and it gives you the ability to truly customize. The loops are to deal with vibration and any movement of the bottles

I think I have the tools. Do you know where to order the tube?flex hoses are convenient, but much more expensive, especially for long runs and they are not a DIY solution. You can DIY the tubes pretty easily with hand tools and it gives you the ability to truly customize. The loops are to deal with vibration and any movement of the bottles

- Messages

- 20,805

- Reaction score

- 15,537

- # of dives

- I'm a Fish!

Swagelok will have them, Parker probably has them, it's standard SS tubing.

I use 1/4 316 stainless tube and flare them to JIC. My bottles have a 1/4 npt to two male JIC tee on each one and they daisy chain. My high bank fills first, then a regulator fills the low bank when the first bank hits 4500.

Stainless and JIC is the cheapest method, but the most time consuming way to plumb.

Stainless and JIC is the cheapest method, but the most time consuming way to plumb.

Gone for diving

Contributor

Stainless and JIC is the cheapest method, but the most time consuming way to plumb.

I assumed hydraulic hose is frowned on?,

For 4500 psi 1/4 hydraulic hose is fine,

6000psi would derate the hose,

- Messages

- 20,805

- Reaction score

- 15,537

- # of dives

- I'm a Fish!

it depends on how it's assembled and cleaned before hand. If you're talking flex hose then it's often got a lot of lube used in manufacturing and assembly that is near impossible to clean. The teflon lined ones for chemical are usually better, but stainless tube is definitely the way to go if you are making a semi-permanent setupI assumed hydraulic hose is frowned on?,

For 4500 psi 1/4 hydraulic hose is fine,

6000psi would derate the hose,

Gone for diving

Contributor

I have used braided ss paintball hose,

It's small ID bore, nicer for fill whips,

I have used hydraulic lines,

but I have access to making my own hyd hoses, so I know how clean it is before crimping,,,

It's small ID bore, nicer for fill whips,

I have used hydraulic lines,

but I have access to making my own hyd hoses, so I know how clean it is before crimping,,,

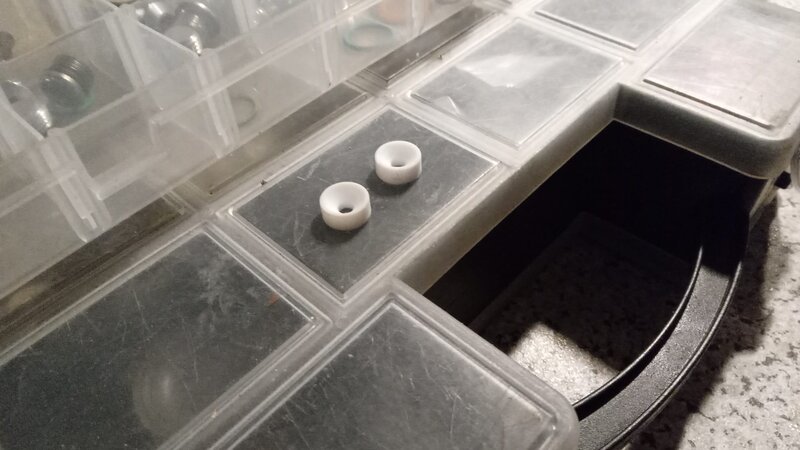

I said I'd post some pictures...

These are the one-way valves I use. Advantage: they're around $10 each and rated to 400bar. Disadvantage: they're designed for hydraulic fluids and don't seal gasses. Solution is in the photo next to it: teflon seats that I put inside the valve. Works like a charm. Those seats require having a friend who can machine those things from a block of teflon.

Digital pressure gauge, costs around $25 in China. This is old-school stuff - these sensors work with a current loop of 4 - 20 mA. Each bank has one of these pressure sensors. A good analogue pressure gauge is more expensive.

All pressures are read by a control unit that operates the solenoid valves:

These solenoids are also from China, price around $70. Material is SS304 and has teflon seats. Can be pulled apart for oxygen cleaning, material is oxygen compatible.

The 2 solenoids in the photo are attached to the 232 and 300 bar banks. At the bottom, these lines connect and go to a needle valve. This valve slows down the fill speed and creates a pressure difference so the control unit can check tank pressure versus bank pressure.

Banks all have DIN valves. I leave 'm open, since the solenoids seal off everything.

These are the one-way valves I use. Advantage: they're around $10 each and rated to 400bar. Disadvantage: they're designed for hydraulic fluids and don't seal gasses. Solution is in the photo next to it: teflon seats that I put inside the valve. Works like a charm. Those seats require having a friend who can machine those things from a block of teflon.

Digital pressure gauge, costs around $25 in China. This is old-school stuff - these sensors work with a current loop of 4 - 20 mA. Each bank has one of these pressure sensors. A good analogue pressure gauge is more expensive.

All pressures are read by a control unit that operates the solenoid valves:

These solenoids are also from China, price around $70. Material is SS304 and has teflon seats. Can be pulled apart for oxygen cleaning, material is oxygen compatible.

The 2 solenoids in the photo are attached to the 232 and 300 bar banks. At the bottom, these lines connect and go to a needle valve. This valve slows down the fill speed and creates a pressure difference so the control unit can check tank pressure versus bank pressure.

Banks all have DIN valves. I leave 'm open, since the solenoids seal off everything.

I'm thinking that old cascade systems that one comes across have brass pigtails and connections. Isn't brass cheaper than SS? Is there some advantage to using SS over brass? (Maximum service pressure, maybe? Or longevity?)

rx7diver

rx7diver

Similar threads

- Replies

- 22

- Views

- 3,222

- Replies

- 77

- Views

- 5,524

- Replies

- 33

- Views

- 2,113

- Replies

- 19

- Views

- 1,910

- Replies

- 0

- Views

- 142