- Messages

- 8,632

- Reaction score

- 7,339

- # of dives

- 2500 - 4999

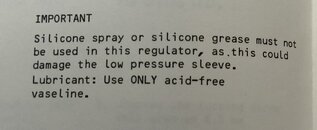

Vaseline, just to reiterate, is not and never has been an acceptable lubricant or assembly grease for a scuba regulator.

Sadly, that hasn't always been the case -- but YIKES to this thread . . .

What's this, old Poseidon outside the reg protection not a lube nor assembly grease