3600 fills do not push 100%. It's closer to 50-55% Yield strength. 4400psi is only 66%. I have been studying mechanics for the last three years and see no reason for why that pressure (3600) is unsafe. I'd even be willing to take a a few tanks that guys have been overfilling for 10-20 years and test the metal with my professors. I think we all accept that service life is degraded through cyclic fatigue. The amount of cycles even at 4000psi that a tank could go through is in the thousands. My tanks will still last 50 years but I probably won't keep mine past 10 years because I don't know the exact effect the loading is having on my individual tank. Hopefully by then, we can get the capacities we want in a reasonable sized and priced tank. Then there will be no need for overfilling.

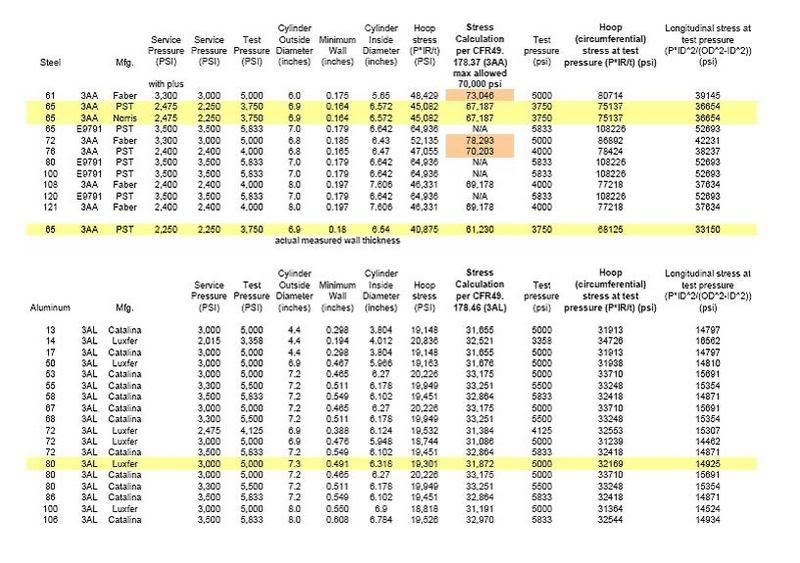

"(2) For cylinders with service pressure of 900 psig or more the

minimum wall must be such that the wall stress at the minimum specified

test pressure may not exceed 67 percent of the minimum tensile strength

of the steel as determined from the physical tests required in

paragraphs (k) and (l) of this section and must be not over 70,000 psi."

The 4130 Alloy used in XS scuba tanks has a minimum Yield of 70,000 psi. The Max stress according to that paragraph could be .67 * 85000psi (The tensile strength) = 57000 psi. Even Hydro pressures (in this case 4400psi) is still below the worst case yield strength for the material.

A 3600 fill is even further from yield. Cyclic fatigue over (in my case 50 fills a year for 10 years) will not be an issue but I will still get rid of the tank because I don't want to see what happens at the end of that curve. I don't think these tanks should be in use for their intended service life nor even half.

I know thats a real elementary way of determining the tanks strength but there is still a large safety factor at 3600. I hope this remains in good spirits.

I said I wasn't going to reply, but this demands clarification. I said "100% duty cycle", not "100% of yield strength". 100% of yield strength is failure!! That cylinder (3AA2250) is designed to withstand 10,000 cycles at 3750 psi. 3600 pushes into the test cycle range of that cylinder. DOT defines any pressurization over 90% of test pressure as a test cycle. So, any pressurization over 3375 counts as a test cycle.

I don't know WHERE you're getting your numbers of: "3600 fills do not push 100%. It's closer to 50-55% Yield strength. 4400psi is only 66%."

You're way off. Minimum burst pressure of that cylinder is 5,625 psi. Yield comes before maximum tensile (burst pressure), and the test pressure is about 67% of the maximum tensile. Unless we're talking about different cylinders, your math is completely wrong.

3600 psi is 64% of burst, probably about 68-71% of yield.

4400 psi is 78% of burst, probably about 82-87% of yield.

In layman's terms, that paragraph you quoted, 40 CFR §178.37(f)(2) means that the burst pressure of the cylinder (maximum tensile strength) cannot be less than 1.5 times the test pressure.

You are confusing wall stress and tensile strength, and then trying to use the maximum wall stress as the burst pressure of the cylinder.

The 70,000 psi is the maximum wall stress limitation calculated from the Bach formula, found in the next paragraph f(3) of that section. It is NOT the maximum pressure in the cylinder. That cylinder is designed with a burst pressure of 1.5 times the test pressure. For a 3AA 2250 that means it has a minimum burst pressure of 5,625 psi. NOT 57,000 psi stated in your post. The paragraph says the wall stress AT TEST PRESSURE cannot exceed 67% of the minimum tensile strength of the steel. When you solve the wall stress calculation found in the next paragraph, you find that for an LP72 (3AA 2250 6.83" x 25"), the wall stress at test pressure is about 54,670 psi. Plug 5625 psi (burst pressure) into that formula, and you are right at the 85,000 psi tensile strength you mentioned.

I don't mean to offend you, and I do hope this remains in good spirits, but you have effectively proven my point. There are all kinds of posts making all kinds of mis-informed, erroneous, and downright dangerous statements. You went to the correct source for the specification, but you did not understand it, and therefore you have come to erroneous conclusions.

By the way, what are you going to do with those damaged cylinders when you "get rid of them"? Are you going to count fill cycles, and destroy them? Or are they going to show up at some swap meet or garage sale where some unsuspecting soul will think he's getting a bargain?

Darrell Garton

CTC Seminars