brysonjk

Contributor

Someone recommended I post this here.

This is a work in progress, but a fun project.

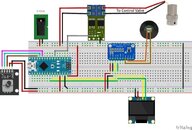

I have created a nitrox blending solution using a Arduino microcontroller, and a proportional control valve. The Arduino has a PID algorithm coded into it that will allow the user to set a specific setpoint and it will maintain that setpoint. For example, turn on the compressor. Long press the knob to calibrate (@20.9%), double click the knob to enter setpoint mode, set the setpoint, and single click to exit. within about 30 seconds the valve will auto modulate and maintain the setpoint.

What makes this nice is that as the pressure increase in the compressor, this will auto-compensate for the additional dwell time of the o2 in the stick. You no longer have to make small adjustments during the filling process.

You can find some of the info here.

github.com

github.com

and here

www.facebook.com

www.facebook.com

Have fun! If there are any other coders/engineers that can help me increase the efficiency of the code, or better tune the PID, that would be awesome!

This is a work in progress, but a fun project.

I have created a nitrox blending solution using a Arduino microcontroller, and a proportional control valve. The Arduino has a PID algorithm coded into it that will allow the user to set a specific setpoint and it will maintain that setpoint. For example, turn on the compressor. Long press the knob to calibrate (@20.9%), double click the knob to enter setpoint mode, set the setpoint, and single click to exit. within about 30 seconds the valve will auto modulate and maintain the setpoint.

What makes this nice is that as the pressure increase in the compressor, this will auto-compensate for the additional dwell time of the o2 in the stick. You no longer have to make small adjustments during the filling process.

You can find some of the info here.

GitHub - brysonjk/NitroxMixer-Public

Contribute to brysonjk/NitroxMixer-Public development by creating an account on GitHub.

and here

Bei Facebook anmelden

Melde dich bei Facebook an, um dich mit deinen Freunden, deiner Familie und Personen, die du kennst, zu verbinden und Inhalte zu teilen.

www.facebook.com

www.facebook.com

Have fun! If there are any other coders/engineers that can help me increase the efficiency of the code, or better tune the PID, that would be awesome!