JamesBon92007

Contributor

- Messages

- 3,213

- Reaction score

- 1,312

- # of dives

- 2500 - 4999

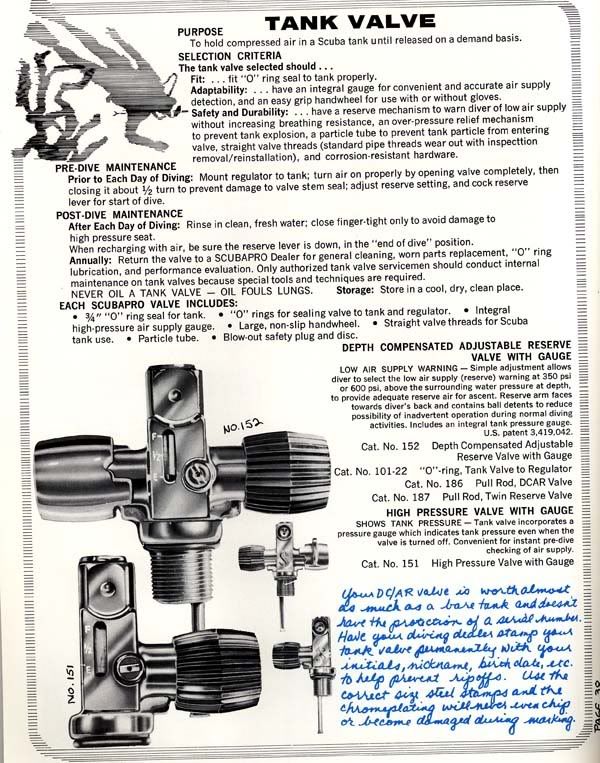

Thanks. So far I found out they have a US Divers manifold and they are 2250 tanks. I'm still trying to find out the hydro dates but apparently I'm not on the same technological level as the seller (I don't know what an iPhone is and don't even have a cel phone).

Well, they are now sitting in my garage

The hard part now is justifying spending the money to get the visual inspections and hydros plus they may need tumbling or whipping (not sure what that is). If they won't hold more air than a single 80 then the cost is probably gonna be more than double just to "look cool." But, if I can manage to come up with a nice, repairable double-hose reg then it would be irresistible. Or perhaps find an old O2 rig and make my own regulator!

I was gonna add a pic but now I don't see how.

Last edited: