Ok all, update as promised.

As I said in the previous post, I refinished the HP seat according to Herman's instructions and it came out great. The assembly went pretty easy without any major issues. If you're going to be working on these DAAM's at all the CustomScubaTools, tools are the way to go. I could have done this with standard tools but the purpose built stuff makes things so much easier. Well worth the money.

As rebuilt, this is a West Warner DAAM. The soft parts (hose loop, mouthpiece, diaphragm, and duckbill) were replaced with silicone. Improved wagon wheel and check valves were also added.

The first stage was replaced with an HPR mainly for ease of use. The rest was rebuilt with a VDH service kit.

Everything went together great and I didn't even destroy the first stage HP gasket this time.

IP was set on a tank with 500 psi. It was adjusted until a slight free flow was observed (about 140 psi) and the backed off just over 1/4 turn. That left me with a stable IP at about 128 psi. There is a small leak that I haven't been able to identify which allows the pressure to bleed off the system in about 18 hours. It may be in the gauge or associated hardware though. I don't think that 18 hours to bleed the regulator qualifies as a significant leak and I don't want to screw up any seats that are set by looking for it.

Here are the photos. Maybe one day I'll get to dive this project.

First stage parts.

First stage assembled.

Body parts.

Main body assembled and ready for the can and HPR.

Installed in can with HPR in place.

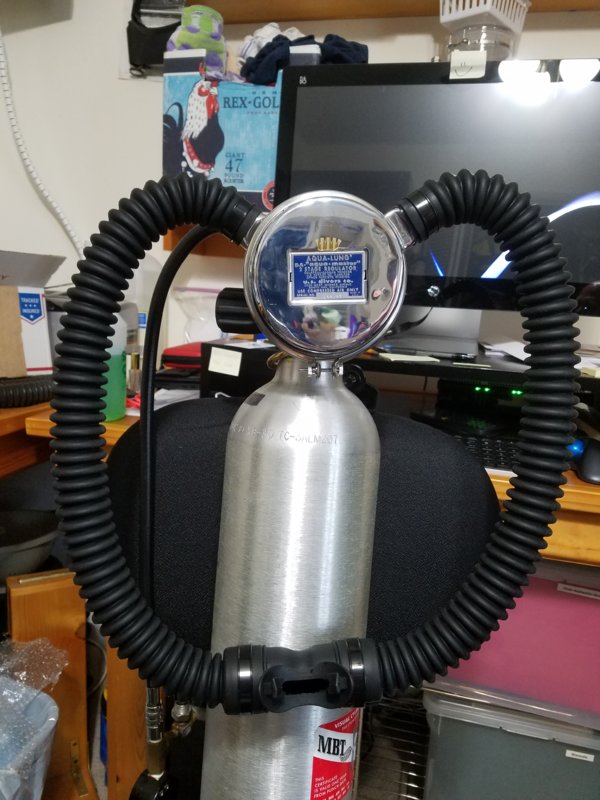

All together. Very Pretty!

Thanks to all here who helped with this project whether that was with suggestion, insight, or getting me the parts I needed. As always this place has been a great help. This project was a lot of fun and will be a complete success once I get the regulator wet.

As I said in the previous post, I refinished the HP seat according to Herman's instructions and it came out great. The assembly went pretty easy without any major issues. If you're going to be working on these DAAM's at all the CustomScubaTools, tools are the way to go. I could have done this with standard tools but the purpose built stuff makes things so much easier. Well worth the money.

As rebuilt, this is a West Warner DAAM. The soft parts (hose loop, mouthpiece, diaphragm, and duckbill) were replaced with silicone. Improved wagon wheel and check valves were also added.

The first stage was replaced with an HPR mainly for ease of use. The rest was rebuilt with a VDH service kit.

Everything went together great and I didn't even destroy the first stage HP gasket this time.

IP was set on a tank with 500 psi. It was adjusted until a slight free flow was observed (about 140 psi) and the backed off just over 1/4 turn. That left me with a stable IP at about 128 psi. There is a small leak that I haven't been able to identify which allows the pressure to bleed off the system in about 18 hours. It may be in the gauge or associated hardware though. I don't think that 18 hours to bleed the regulator qualifies as a significant leak and I don't want to screw up any seats that are set by looking for it.

Here are the photos. Maybe one day I'll get to dive this project.

First stage parts.

First stage assembled.

Body parts.

Main body assembled and ready for the can and HPR.

Installed in can with HPR in place.

All together. Very Pretty!

Thanks to all here who helped with this project whether that was with suggestion, insight, or getting me the parts I needed. As always this place has been a great help. This project was a lot of fun and will be a complete success once I get the regulator wet.