The most common pressure transducers use a current-loop. It's an industry standard that has been in use for decades.

The transducer can be connected with a very long wire (half a mile is no problem at all). A fault can be detected easily: 0mA or no current means a disconnected transducer or an error condition while 4mA means a reading of zero.

These transducers are neatly priced, accurate and I have been using them for over 2 years without a glitch. A 60MPa transducer has a range that is too large - better options are 25MPa, 30MPa or 40MPa, depending on the maximum pressure that you want to measure.

How does it work?

First you need a power source, anything from 12V to 36V DC will do. The transducer is connected to the power source and will send a current. Most electronics can't do much with a current, so it's translated to a voltage (which is what the transducer mentioned by @Rol diy does). That voltage can then be sent to a analog/digital converter that a processor can use.

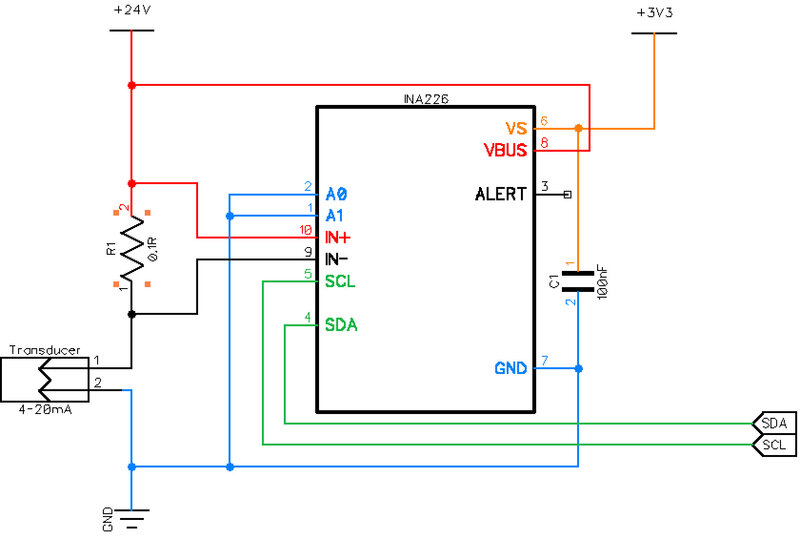

Texas Instruments created a tiny little chip that does all of that, the INA226:

The current loop runs from the positive terminal of the DC power supply over a resistor (0.1 Ohm / 1% precision), then to the transducer and finally back to the ground terminal of the power supply.

The chip measures the voltage difference over the precision resistor and translates that into a 16-bit value, which is from 0 to 65535.

That value is sent over the I2C bus (SDA/SCL pins) to an arduino / raspberry / esp32 / other computer.

Measuring the output pressure of the compressor with a 40MPa transducer (400bar / 5800psi) gives a value of 13107 for zero pressure and 65535 for max pressure. That's over 52000 steps for 5800psi - enough precision for an accurate reading.

Measuring the pressure of bank(s) is a matter of adding more of these chips (up to 16) and transducers, the same power supply can be used for all of them.

The transducer can be connected with a very long wire (half a mile is no problem at all). A fault can be detected easily: 0mA or no current means a disconnected transducer or an error condition while 4mA means a reading of zero.

These transducers are neatly priced, accurate and I have been using them for over 2 years without a glitch. A 60MPa transducer has a range that is too large - better options are 25MPa, 30MPa or 40MPa, depending on the maximum pressure that you want to measure.

How does it work?

First you need a power source, anything from 12V to 36V DC will do. The transducer is connected to the power source and will send a current. Most electronics can't do much with a current, so it's translated to a voltage (which is what the transducer mentioned by @Rol diy does). That voltage can then be sent to a analog/digital converter that a processor can use.

Texas Instruments created a tiny little chip that does all of that, the INA226:

The current loop runs from the positive terminal of the DC power supply over a resistor (0.1 Ohm / 1% precision), then to the transducer and finally back to the ground terminal of the power supply.

The chip measures the voltage difference over the precision resistor and translates that into a 16-bit value, which is from 0 to 65535.

That value is sent over the I2C bus (SDA/SCL pins) to an arduino / raspberry / esp32 / other computer.

Measuring the output pressure of the compressor with a 40MPa transducer (400bar / 5800psi) gives a value of 13107 for zero pressure and 65535 for max pressure. That's over 52000 steps for 5800psi - enough precision for an accurate reading.

Measuring the pressure of bank(s) is a matter of adding more of these chips (up to 16) and transducers, the same power supply can be used for all of them.