You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Complete ScubaPro MK2/R190/R380 Repair Steps/Parts List...

- Thread starter WolfPackDiver

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

WolfPackDiver

Registered

General Notes

The following information covers the steps I use to perform the annual service on my regulators. My qualifications are that I am Ocean Engineer working in the underwater equipment industry and make a living designing pressure housings and related equipment. I am NOT associated with ScubaPro, ScubaTools.com, or any dive shop and have no "official" ScubaPro training. As with all diving related activities, there is risk involved with servicing regulators. My regulators keep me alive underwater. I personally do not trust a stranger with my life. I follow these steps only on my own personal gear and have had absolute 100% success with them. If you have any suggestions on how to better the techniques or materials, please let me know. Also, this was a lot of typing and I may (did) make some typo's somewhere. Let me know if you see any and I'll fix asap. Thanks and good luck!

O-Rings

O-rings come in many sizes, materials, and hardness. It is important to get these correct. I use the Parker O-Ring Handbook(http://www.parker.com/parker/jsp/documentdisplay.jsp?mgmtid=8a443ecbca714110VgnVCM10000048021dacRCRD) for both my at-work designs and repairing my scuba regulators. Always lubricate any o-ring with lubricant. I use Christo-Lube MCG-129 (oxygen compatible). To properly lubricate an o-ring, squeeze a small amount onto your finger-tip and lightly rub onto the o-ring. The o-ring should glisten but not have globs of lubricant.

According to the Parker O-ring guide, if there is metal to metal (no gap) around the o-ring, sealing pressures up to 200,000 psi have been maintained with Shore-A 70 durometer o-rings.

------------------------------------------------------------------------------------------------------------------

Work Flow

1.Mount 1st stage on air cylinder

2.Remove hoses and 2nd stages

3.Disassemble/Service/Rebuild 1st stage

4.Disassemble/Service/Rebuild hoses

5.Disassemble/Service/Rebuild 2nd stages

6.Install inflater hose (with Intermedia Pressure (IP) gauge) on 1st stage

7.Install one 2nd stage with inline adjustment tool on 1st stage

8.Open air to 1st stage. The IP should be between 125 and 140 psi.

9.Your 2nd stage will likely free flow. Dial in the orifice until it stops free flowing, then about 30 degrees more.

10.Check your inhalation effort using a Magnahelic. 1.2"-1.8" is ScubaPro acceptable range. I like mine around 1.5", Adjust with inline tool and 1/4" nut driver.

11.Turn off air, purge.

12.Install octopus 2nd stage with inline adjustment tool.

13.Open air to 1st stage. The IP should still be between 125 and 140 psi.

14.Your octopus 2nd stage will likely free flow. Dial in the orifice until it stops free flowing, then about 30 degrees more.

15.Check your inhalation effort using a Magnahelic. 1.2"-1.8" is ScubaPro acceptable range. I like mine around 1.5", Adjust with inline tool and 1/4" nut driver.

16.Shut down air, purge.

Equipment covered in this document:

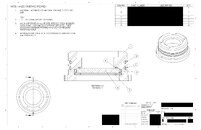

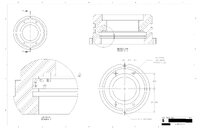

1st Stage: ScubaPro MK2 (or MK2+), Yoke Style

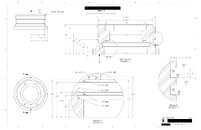

2nd Stage: ScubaPro R190 (or R380)

------------------------------------------------------------------------------------------------------------------

Tools:

#A. ScubaPro Just-A-Wrench. (Scubapro Just-A-Wrench, Aluminum) I find this easier to use than the multi-tool/finger-$%^&er.

#B. Wiha 1/4" Nut Driver (1/4, $8). This has a thinner wall than others enabling it to insert further into the valve body.

#C. Inline adjustment tool

#D. PeterBuilt Spanner #4 (Hook Spanner #4 (1.4 in. diameter), $13.50)

#E. Yoke nut socket (1" Yoke Nut Socket, #20)

#F. Custom face cover remover. PVC T. 2.25" OD and 2.75"OD. Use band saw to cut out and leave two "teeth" that will fit into face slots. Home Depot: NIBCO 2 In. x 2 In. x 1 1/2 In. PVC DWV Sanitary Tee Reducing All Hub Model # C4811. Store SKU # 641165. Works great.

------------------------------------------------------------------------------------------------------------------

Supplies:

Christo-Lube MCG-129.

Simple Green Cleaning Solution (You can find at Target or similar stores), use 1:20 SG:Water.

Compressed air to dry parts leaving minimal particle traces.

------------------------------------------------------------------------------------------------------------------

First Step

1.Mount MK2 on a cylinder.

2.Remove all hoses using a 9/16 wrench.

3.Remove 2nd stages from hoses using a 9/16" or adjustable wrench and/or tool #A.

4.Organize: I like to use plastic dinner trays or bins to keep the parts segregated. I use one bin per regulator.

Also, get a coffee mug and put a zip-lock bag inside to hold the old o-rings/nuts/etc you remove.

------------------------------------------------------------------------------------------------------------------

Hose Cleaning

1.Place all disassembled parts into a tub of 1 part simple green, 20 parts water.

2.Leave for 5-10 minutes depending on how much dirt/grime is on regulator.

3.Use an old tooth brush to scrub biological grime, rinse/repeat in the simple green.

4.Remove parts from solution, rinse thoroughly with water and dry.

------------------------------------------------------------------------------------------------------------------

MK2 Disassembly (Leave connected to air cylinder with pressure OFF)

1.Remove yoke screw (by hand) (P/N 10200008)

2.Remove "Soft cap" from the rear cap (by hand or flathead screwdriver) (P/N 10060021)

3.Slide off inlet protector (rubber cap) (P/N 10101212)

4.Screw in a 4" long brass 7/16"-20 socket head cap screw to the high pressure port (HP)-->strongest port

5.Use a #D tool or similar spanner wrench to remove the cap (P/N 10102109) (Be careful not to lose any of the plastic shims)

Note: the spring and piston assembly will come out in the cap. Be very careful with the small end of the piston. This is the sealing surface!

6.Disassemble spring and piston assembly by hand. May need to rock piston gently to free the o-ring

7.Push the HP seat out of the piston using a pick, stiff wire, etc.

8.Remove the two o-rings from the piston using a pick or by hand. Be careful not to scratch anything!

9.Remove remaining regulator parts from your air cylinder. Unscrew the yoke retaining nut (P/N 10103115) using tool #E (1" variety) or similar.

10.Remove yoke handle, rubber spacer by hand.

11.Pry out the retaining external tooth washer with a flathead screwdriver, careful with the regs...

12.Remove filter.

13.Remove all remaining pressure port plugs.

Note: put all used o-rings in your zip-lock bag in the coffee cup.

------------------------------------------------------------------------------------------------------------------

MK2 Cleaning

1.Place all disassembled parts into a tub of 1 part simple green, 20 parts water.

2.Leave for 5-10 minutes depending on how much dirt/grime is on regulator.

3.Use an old tooth brush to scrub biological grime, rinse/repeat in the simple green.

4.Remove parts from solution, rinse thoroughly with water and dry.

------------------------------------------------------------------------------------------------------------------

MK2 Service/Rebuild

Repair Kit:

Item

ScubaPro P/N

Part

McMaster P/N

Description

1. 01050138, O-Ring AS568A-2-011, Shore A 90, McMaster #5308T12 , Buna-Nitrile (High Pressure Port)

2. 01050132, O-Ring AS568A-2-010, Shore A 70, McMaster #9555K11 , Buna-Nitrile (Low Pressure Ports)

3. 01050177, O-Ring AS568A-2-022, Shore A 70, McMaster #9555K46, Buna-Nitrile (Large Piston Base Ring)

4. 01050126, O-Ring AS568A-2-008, Shore A 90, McMaster #5308T117, Buna-Nitrile (Small Piston Neck Ring)

5. 10102103, HP Seat, -----, Still don't have a good supplier of these. I tend to buy new old stock where possible. Dimensions are 0.185"OD, 0.138"thk +/-.003"

*Christo-Lube MCG-129 lubricant for o-rings.

*Optional: Conical Filter: I believe trident sells these...anyone have a P/N??

*Optional: External tooth washer

------------------------------------------------------------------------------------------------------------------

1.Install filter and tooth-washer back in yoke retaining nut (press in by hand).

2.Replace o-ring with standard AS568A-2-015 Shore A-90, Buna-N. McMaster #5308T124. Make sure to lightly coat with christo-lube. ("Make it glisten, not glob...")

3.Hold rubber spacer (P/N 10044021) on regulator body and install yoke and retaining nut with filter. Tighten snugly with socket tool #E. SP recommends 266 in-lbs/30N-m.

4.Replace piston large o-ring with AS568A-2-022 Shore A durometer 70. McMaster #9555K46, again, lube with cristo-lube

5.Replace piston neck o-ring with AS568A-2-008 Shore A durometer 90. McMaster #5308T117.

6.Replace teflon HP seat. Still don't have a good supplier of these. I tend to buy new old stock where possible. Dimensions are 0.185"OD, 0.138"thk +/-.003"

7.Replace shims on spring. A daub of Christo-lube will hold it on the spring during assembly.

8.Install piston back into cap (by hand), ensuring good o-ring seal.

9.Place spring over piston.

10.Gently align piston/seat with body shaft and screw the cap assembly back to the main body.

11.I install cap to "snug" with the spanner (Remember to use your handy 7/16-20 bolt tool in the HP port). SP doesn't have a torque recommendation for this that I know of. I've never had an issue with this.

12.Replace all rubber boots/caps, etc.

13.Install back on air cylinder.

14.Replace LP and HP port plugs as necessary (remember to install new o-rings).

The following information covers the steps I use to perform the annual service on my regulators. My qualifications are that I am Ocean Engineer working in the underwater equipment industry and make a living designing pressure housings and related equipment. I am NOT associated with ScubaPro, ScubaTools.com, or any dive shop and have no "official" ScubaPro training. As with all diving related activities, there is risk involved with servicing regulators. My regulators keep me alive underwater. I personally do not trust a stranger with my life. I follow these steps only on my own personal gear and have had absolute 100% success with them. If you have any suggestions on how to better the techniques or materials, please let me know. Also, this was a lot of typing and I may (did) make some typo's somewhere. Let me know if you see any and I'll fix asap. Thanks and good luck!

O-Rings

O-rings come in many sizes, materials, and hardness. It is important to get these correct. I use the Parker O-Ring Handbook(http://www.parker.com/parker/jsp/documentdisplay.jsp?mgmtid=8a443ecbca714110VgnVCM10000048021dacRCRD) for both my at-work designs and repairing my scuba regulators. Always lubricate any o-ring with lubricant. I use Christo-Lube MCG-129 (oxygen compatible). To properly lubricate an o-ring, squeeze a small amount onto your finger-tip and lightly rub onto the o-ring. The o-ring should glisten but not have globs of lubricant.

According to the Parker O-ring guide, if there is metal to metal (no gap) around the o-ring, sealing pressures up to 200,000 psi have been maintained with Shore-A 70 durometer o-rings.

------------------------------------------------------------------------------------------------------------------

Work Flow

1.Mount 1st stage on air cylinder

2.Remove hoses and 2nd stages

3.Disassemble/Service/Rebuild 1st stage

4.Disassemble/Service/Rebuild hoses

5.Disassemble/Service/Rebuild 2nd stages

6.Install inflater hose (with Intermedia Pressure (IP) gauge) on 1st stage

7.Install one 2nd stage with inline adjustment tool on 1st stage

8.Open air to 1st stage. The IP should be between 125 and 140 psi.

9.Your 2nd stage will likely free flow. Dial in the orifice until it stops free flowing, then about 30 degrees more.

10.Check your inhalation effort using a Magnahelic. 1.2"-1.8" is ScubaPro acceptable range. I like mine around 1.5", Adjust with inline tool and 1/4" nut driver.

11.Turn off air, purge.

12.Install octopus 2nd stage with inline adjustment tool.

13.Open air to 1st stage. The IP should still be between 125 and 140 psi.

14.Your octopus 2nd stage will likely free flow. Dial in the orifice until it stops free flowing, then about 30 degrees more.

15.Check your inhalation effort using a Magnahelic. 1.2"-1.8" is ScubaPro acceptable range. I like mine around 1.5", Adjust with inline tool and 1/4" nut driver.

16.Shut down air, purge.

Equipment covered in this document:

1st Stage: ScubaPro MK2 (or MK2+), Yoke Style

2nd Stage: ScubaPro R190 (or R380)

------------------------------------------------------------------------------------------------------------------

Tools:

#A. ScubaPro Just-A-Wrench. (Scubapro Just-A-Wrench, Aluminum) I find this easier to use than the multi-tool/finger-$%^&er.

#B. Wiha 1/4" Nut Driver (1/4, $8). This has a thinner wall than others enabling it to insert further into the valve body.

#C. Inline adjustment tool

#D. PeterBuilt Spanner #4 (Hook Spanner #4 (1.4 in. diameter), $13.50)

#E. Yoke nut socket (1" Yoke Nut Socket, #20)

#F. Custom face cover remover. PVC T. 2.25" OD and 2.75"OD. Use band saw to cut out and leave two "teeth" that will fit into face slots. Home Depot: NIBCO 2 In. x 2 In. x 1 1/2 In. PVC DWV Sanitary Tee Reducing All Hub Model # C4811. Store SKU # 641165. Works great.

------------------------------------------------------------------------------------------------------------------

Supplies:

Christo-Lube MCG-129.

Simple Green Cleaning Solution (You can find at Target or similar stores), use 1:20 SG:Water.

Compressed air to dry parts leaving minimal particle traces.

------------------------------------------------------------------------------------------------------------------

First Step

1.Mount MK2 on a cylinder.

2.Remove all hoses using a 9/16 wrench.

3.Remove 2nd stages from hoses using a 9/16" or adjustable wrench and/or tool #A.

4.Organize: I like to use plastic dinner trays or bins to keep the parts segregated. I use one bin per regulator.

Also, get a coffee mug and put a zip-lock bag inside to hold the old o-rings/nuts/etc you remove.

------------------------------------------------------------------------------------------------------------------

Hose Cleaning

1.Place all disassembled parts into a tub of 1 part simple green, 20 parts water.

2.Leave for 5-10 minutes depending on how much dirt/grime is on regulator.

3.Use an old tooth brush to scrub biological grime, rinse/repeat in the simple green.

4.Remove parts from solution, rinse thoroughly with water and dry.

------------------------------------------------------------------------------------------------------------------

MK2 Disassembly (Leave connected to air cylinder with pressure OFF)

1.Remove yoke screw (by hand) (P/N 10200008)

2.Remove "Soft cap" from the rear cap (by hand or flathead screwdriver) (P/N 10060021)

3.Slide off inlet protector (rubber cap) (P/N 10101212)

4.Screw in a 4" long brass 7/16"-20 socket head cap screw to the high pressure port (HP)-->strongest port

5.Use a #D tool or similar spanner wrench to remove the cap (P/N 10102109) (Be careful not to lose any of the plastic shims)

Note: the spring and piston assembly will come out in the cap. Be very careful with the small end of the piston. This is the sealing surface!

6.Disassemble spring and piston assembly by hand. May need to rock piston gently to free the o-ring

7.Push the HP seat out of the piston using a pick, stiff wire, etc.

8.Remove the two o-rings from the piston using a pick or by hand. Be careful not to scratch anything!

9.Remove remaining regulator parts from your air cylinder. Unscrew the yoke retaining nut (P/N 10103115) using tool #E (1" variety) or similar.

10.Remove yoke handle, rubber spacer by hand.

11.Pry out the retaining external tooth washer with a flathead screwdriver, careful with the regs...

12.Remove filter.

13.Remove all remaining pressure port plugs.

Note: put all used o-rings in your zip-lock bag in the coffee cup.

------------------------------------------------------------------------------------------------------------------

MK2 Cleaning

1.Place all disassembled parts into a tub of 1 part simple green, 20 parts water.

2.Leave for 5-10 minutes depending on how much dirt/grime is on regulator.

3.Use an old tooth brush to scrub biological grime, rinse/repeat in the simple green.

4.Remove parts from solution, rinse thoroughly with water and dry.

------------------------------------------------------------------------------------------------------------------

MK2 Service/Rebuild

Repair Kit:

Item

ScubaPro P/N

Part

McMaster P/N

Description

1. 01050138, O-Ring AS568A-2-011, Shore A 90, McMaster #5308T12 , Buna-Nitrile (High Pressure Port)

2. 01050132, O-Ring AS568A-2-010, Shore A 70, McMaster #9555K11 , Buna-Nitrile (Low Pressure Ports)

3. 01050177, O-Ring AS568A-2-022, Shore A 70, McMaster #9555K46, Buna-Nitrile (Large Piston Base Ring)

4. 01050126, O-Ring AS568A-2-008, Shore A 90, McMaster #5308T117, Buna-Nitrile (Small Piston Neck Ring)

5. 10102103, HP Seat, -----, Still don't have a good supplier of these. I tend to buy new old stock where possible. Dimensions are 0.185"OD, 0.138"thk +/-.003"

*Christo-Lube MCG-129 lubricant for o-rings.

*Optional: Conical Filter: I believe trident sells these...anyone have a P/N??

*Optional: External tooth washer

------------------------------------------------------------------------------------------------------------------

1.Install filter and tooth-washer back in yoke retaining nut (press in by hand).

2.Replace o-ring with standard AS568A-2-015 Shore A-90, Buna-N. McMaster #5308T124. Make sure to lightly coat with christo-lube. ("Make it glisten, not glob...")

3.Hold rubber spacer (P/N 10044021) on regulator body and install yoke and retaining nut with filter. Tighten snugly with socket tool #E. SP recommends 266 in-lbs/30N-m.

4.Replace piston large o-ring with AS568A-2-022 Shore A durometer 70. McMaster #9555K46, again, lube with cristo-lube

5.Replace piston neck o-ring with AS568A-2-008 Shore A durometer 90. McMaster #5308T117.

6.Replace teflon HP seat. Still don't have a good supplier of these. I tend to buy new old stock where possible. Dimensions are 0.185"OD, 0.138"thk +/-.003"

7.Replace shims on spring. A daub of Christo-lube will hold it on the spring during assembly.

8.Install piston back into cap (by hand), ensuring good o-ring seal.

9.Place spring over piston.

10.Gently align piston/seat with body shaft and screw the cap assembly back to the main body.

11.I install cap to "snug" with the spanner (Remember to use your handy 7/16-20 bolt tool in the HP port). SP doesn't have a torque recommendation for this that I know of. I've never had an issue with this.

12.Replace all rubber boots/caps, etc.

13.Install back on air cylinder.

14.Replace LP and HP port plugs as necessary (remember to install new o-rings).

Nice.

I use 4 to 6 in 3/8x24 (SAE fine) bolts and nuts, you missed the bolt 7/16 bolt in the tools list. (spent CO2 cartriges also work) These fit nicely into the LP ports. I install them finger tight, back off a little then pull the nut up by hand to act as a jam nut. Then the bolt can be placed in a vise for easier access and a more stable work platform. If you have a tight piston cap, you can put 2 bolts in the reg and clamp both in a vise, giving you a better hold on the reg with no damage to the body.

By the way, it is possible to flip the HP seat and use the other side as long as it is in good condition.

I use 4 to 6 in 3/8x24 (SAE fine) bolts and nuts, you missed the bolt 7/16 bolt in the tools list. (spent CO2 cartriges also work) These fit nicely into the LP ports. I install them finger tight, back off a little then pull the nut up by hand to act as a jam nut. Then the bolt can be placed in a vise for easier access and a more stable work platform. If you have a tight piston cap, you can put 2 bolts in the reg and clamp both in a vise, giving you a better hold on the reg with no damage to the body.

By the way, it is possible to flip the HP seat and use the other side as long as it is in good condition.

I was going to say "PM sent re typos", but I found so few . . . So:Also, this was a lot of typing and I may (did) make some typo's somewhere. Let me know if you see any and I'll fix asap.

Under Work Flow, item 6, you mistyped inflator and intermediate.

In Rebuild, step 6, Teflon should be capitalized.

And a stylistic nit: in step 7, instead of daub, you might have meant dab.

Nice job. Thank you for all the work you put into it.

k

Texfrazer

Guest

Awesome write-up! Thanks!

A few more of these for the various 1st and 2nd stages and we could have our own SB regulator repair manual.

A few more of these for the various 1st and 2nd stages and we could have our own SB regulator repair manual.

superstar

Contributor

Lets put together how to videos on youtube.

I love you guys!!

I'm scared to say this and if you don't hear from me again the scubapro police have locked me away in the gulag prison send help!! (JOKE... GULP...)

After messing as a DIY guy and heckling my local dive shop owner with questions he put me on the books and sent me to scubapro school.

Honestly I am so impressed by scubapro and how they run their operation. I'm not speaking on behalf of scubapro and this is my own opinion, but they also are subject to litigation against them. Most of the wall the DIY guy face.. Getting parts... information on regs must all come from prior experience with litigation. Again my own opinion, If you put a walmart plastic tie wrap on the mouth piece and don't use the scubapro one... they are off the hook. Get what I'm trying to say? You use non scubapro o-rings and the diver expires they are off the hook. Think of all the dumb people out there. It's a form of protection for scubapro. It's a numbers game. If 99.9% DIY right there is always a chance the .1% will kill themslef, their familly takes SP to court and the jury says 'why did scubapro give this guy the facility to fix his own regs?!?!?' Well this is why they don't in my opinion. It's not because of the 99% out there.. it's because of the numbers. Sooner or later someone will or has gone to a wonky court and a jury of non divers will put the blame on SP.

So the thinking is it keeps costs down. To fight off litigation they partition themselves so their butt is always covered. They are divers too, but have some really space age stuff going on in Italy they have to pay for. If the one jerk gets a 1 Million settlement that's 1 million they have to make up in sale price.

I'm not saying it does'nt suck.... it does suck big time that the world is this F8ed up. To me it's not SP's blame. Now I question myself. What the heck will happen if I say your tank o-ring is a #14 keep some in your dive kit. The guy dies because he ate too many cheeseburgers and the family says It's because I gave him a #14 to put in his kit. Some fat **** on the jury watches to much star trek and says.. hey the challenger spaceshuttle blew up because of an o-ring, it must be because the instructor gave them an o-ring!!! I'm smart and you mr. instructor are liable for this guy... We live in a society that somone can pour mcdonalds coffee on their balls and sue Mcdonalds and win. i did not think it was hot..?!?!?!?!? regardless of the temp... coffee=hot you pour it on your lap you get burned....

I have a wife, house, 401K etc.. I want to keep all that. So what do you pay for in those kits? In a $50 kit I bet it's $10 Dive shop profit, $10 SP profit & $30 Insurance, lawyers, courts, bloodsuckers.

The other side of the coin is crappy service that is pushing us DIY guys into doing what we do. We pay our hard cash to get service and when we go to use it after geting it serviced from a LDS and it leaks....it pushes DIY guys to learn and do it themselves because they want quality in their gear. We DIY guys get pissed because we pay top dollar and get crap service.

So I say do what I did, SP needs good reg techs and the people on here are very detail oriented. Go to a local dive shop and say I want to be put on the books (so you are on the insurance) pay me $1 an hour and send me to scubapro school because I want to DIY. If they don't then it's their loss because detail oriented reg techs are hard to come by. There are plenty of LDS out there that will take you up on your offer. The one I'm with now is plenty willing to pay me in peanuts lol.

Just something to think about and wanted to share my experiences. The crappy reg techs that charge top dollar and blame it on SP should go. But they have it good, they get to charge you $70 bucks and go out back and smoke a cig rinse your gear in water. So do what I did, become a detail oriented guy and push out the crappy reg techs. SP wants you and the other guys out. This will only benifit them in the long run.

After learning all this scubapro is still and always will be my choice of dive gear for regs. they are awesome..

dive safe all

I'm scared to say this and if you don't hear from me again the scubapro police have locked me away in the gulag prison send help!! (JOKE... GULP...)

After messing as a DIY guy and heckling my local dive shop owner with questions he put me on the books and sent me to scubapro school.

Honestly I am so impressed by scubapro and how they run their operation. I'm not speaking on behalf of scubapro and this is my own opinion, but they also are subject to litigation against them. Most of the wall the DIY guy face.. Getting parts... information on regs must all come from prior experience with litigation. Again my own opinion, If you put a walmart plastic tie wrap on the mouth piece and don't use the scubapro one... they are off the hook. Get what I'm trying to say? You use non scubapro o-rings and the diver expires they are off the hook. Think of all the dumb people out there. It's a form of protection for scubapro. It's a numbers game. If 99.9% DIY right there is always a chance the .1% will kill themslef, their familly takes SP to court and the jury says 'why did scubapro give this guy the facility to fix his own regs?!?!?' Well this is why they don't in my opinion. It's not because of the 99% out there.. it's because of the numbers. Sooner or later someone will or has gone to a wonky court and a jury of non divers will put the blame on SP.

So the thinking is it keeps costs down. To fight off litigation they partition themselves so their butt is always covered. They are divers too, but have some really space age stuff going on in Italy they have to pay for. If the one jerk gets a 1 Million settlement that's 1 million they have to make up in sale price.

I'm not saying it does'nt suck.... it does suck big time that the world is this F8ed up. To me it's not SP's blame. Now I question myself. What the heck will happen if I say your tank o-ring is a #14 keep some in your dive kit. The guy dies because he ate too many cheeseburgers and the family says It's because I gave him a #14 to put in his kit. Some fat **** on the jury watches to much star trek and says.. hey the challenger spaceshuttle blew up because of an o-ring, it must be because the instructor gave them an o-ring!!! I'm smart and you mr. instructor are liable for this guy... We live in a society that somone can pour mcdonalds coffee on their balls and sue Mcdonalds and win. i did not think it was hot..?!?!?!?!? regardless of the temp... coffee=hot you pour it on your lap you get burned....

I have a wife, house, 401K etc.. I want to keep all that. So what do you pay for in those kits? In a $50 kit I bet it's $10 Dive shop profit, $10 SP profit & $30 Insurance, lawyers, courts, bloodsuckers.

The other side of the coin is crappy service that is pushing us DIY guys into doing what we do. We pay our hard cash to get service and when we go to use it after geting it serviced from a LDS and it leaks....it pushes DIY guys to learn and do it themselves because they want quality in their gear. We DIY guys get pissed because we pay top dollar and get crap service.

So I say do what I did, SP needs good reg techs and the people on here are very detail oriented. Go to a local dive shop and say I want to be put on the books (so you are on the insurance) pay me $1 an hour and send me to scubapro school because I want to DIY. If they don't then it's their loss because detail oriented reg techs are hard to come by. There are plenty of LDS out there that will take you up on your offer. The one I'm with now is plenty willing to pay me in peanuts lol.

Just something to think about and wanted to share my experiences. The crappy reg techs that charge top dollar and blame it on SP should go. But they have it good, they get to charge you $70 bucks and go out back and smoke a cig rinse your gear in water. So do what I did, become a detail oriented guy and push out the crappy reg techs. SP wants you and the other guys out. This will only benifit them in the long run.

After learning all this scubapro is still and always will be my choice of dive gear for regs. they are awesome..

dive safe all

R

redacted

Guest

I love you guys!!

I'm scared to say this and if you don't hear from me again the scubapro police have locked me away in the gulag prison send help!! (JOKE... GULP...)

After messing as a DIY guy and heckling my local dive shop owner with questions he put me on the books and sent me to scubapro school.

Honestly I am so impressed by scubapro and how they run their operation. I'm not speaking on behalf of scubapro and this is my own opinion, but they also are subject to litigation against them. Most of the wall the DIY guy face.. Getting parts... information on regs must all come from prior experience with litigation. Again my own opinion, If you put a walmart plastic tie wrap on the mouth piece and don't use the scubapro one... they are off the hook. Get what I'm trying to say? You use non scubapro o-rings and the diver expires they are off the hook. Think of all the dumb people out there. It's a form of protection for scubapro. It's a numbers game. If 99.9% DIY right there is always a chance the .1% will kill themslef, their familly takes SP to court and the jury says 'why did scubapro give this guy the facility to fix his own regs?!?!?' Well this is why they don't in my opinion. It's not because of the 99% out there.. it's because of the numbers. Sooner or later someone will or has gone to a wonky court and a jury of non divers will put the blame on SP.

So the thinking is it keeps costs down. To fight off litigation they partition themselves so their butt is always covered. They are divers too, but have some really space age stuff going on in Italy they have to pay for. If the one jerk gets a 1 Million settlement that's 1 million they have to make up in sale price.

I'm not saying it does'nt suck.... it does suck big time that the world is this F8ed up. To me it's not SP's blame. Now I question myself. What the heck will happen if I say your tank o-ring is a #14 keep some in your dive kit. The guy dies because he ate too many cheeseburgers and the family says It's because I gave him a #14 to put in his kit. Some fat **** on the jury watches to much star trek and says.. hey the challenger spaceshuttle blew up because of an o-ring, it must be because the instructor gave them an o-ring!!! I'm smart and you mr. instructor are liable for this guy... We live in a society that somone can pour mcdonalds coffee on their balls and sue Mcdonalds and win. i did not think it was hot..?!?!?!?!? regardless of the temp... coffee=hot you pour it on your lap you get burned....

I have a wife, house, 401K etc.. I want to keep all that. So what do you pay for in those kits? In a $50 kit I bet it's $10 Dive shop profit, $10 SP profit & $30 Insurance, lawyers, courts, bloodsuckers.

The other side of the coin is crappy service that is pushing us DIY guys into doing what we do. We pay our hard cash to get service and when we go to use it after geting it serviced from a LDS and it leaks....it pushes DIY guys to learn and do it themselves because they want quality in their gear. We DIY guys get pissed because we pay top dollar and get crap service.

So I say do what I did, SP needs good reg techs and the people on here are very detail oriented. Go to a local dive shop and say I want to be put on the books (so you are on the insurance) pay me $1 an hour and send me to scubapro school because I want to DIY. If they don't then it's their loss because detail oriented reg techs are hard to come by. There are plenty of LDS out there that will take you up on your offer. The one I'm with now is plenty willing to pay me in peanuts lol.

Just something to think about and wanted to share my experiences. The crappy reg techs that charge top dollar and blame it on SP should go. But they have it good, they get to charge you $70 bucks and go out back and smoke a cig rinse your gear in water. So do what I did, become a detail oriented guy and push out the crappy reg techs. SP wants you and the other guys out. This will only benifit them in the long run.

After learning all this scubapro is still and always will be my choice of dive gear for regs. they are awesome..

dive safe all

I don't believe the liability excuse for a minute. Scubapro and others restrict parts access to force divers to resort to their LDS for service and to keep independent service techs from competing with LDSs.

If it were simply Scubapro USA trying to cover their a$$e$, they would not be working so hard to shut down foreign parts sources that used to sell to USA customers. Scubapro service kits were available from Scubastore.com up until about 10 years ago at very reasonable prices. First the availability of parts were shut down and then Scubapro products in general.

BTW, I'm sure there are aftermarket sources for Mk2 HP seats (and others) but I'm still searching. I am using a Trident aftermarket seat that they sell as a Sherwood seat in one of my Mk2s. It seems to work fine but has not seen much use yet.

halocline

Contributor

I don't believe the liability excuse for a minute. Scubapro and others restrict parts access to force divers to resort to their LDS for service and to keep independent service techs from competing with LDSs.

Exactly. And I'd like to know about a single case of a scuba diver suing a manufacturer for a divers' death that did not involve serious design problems.

The Mcdonalds case that was referred to is misleading. A better analogy would have been if the person who got burned sued the company that produced the coffee. If you buy SP parts, and your reg fails, there isn't a court in the world that would successfully sue SP unless the parts themselves were proven faulty. If the opposite were true, you'd NEVER be able to buy auto parts.

superstar

Contributor

I do not buy into the liability crap either, we can buy auto parts all day long and fix our own cars and crash them into other people and even cause death. Have you ever heard of a lawsuit that blamed the accident on the fact that the car owner installed his own windshield wiper blades. An attorney would sue rainx for making the wipers, wallmart for selling you the wipers, the printer that printed the instalation instructions, and sue China for making the blades. The litigation would never end. Imagine what would develope if the auto industry only sold parts to dealers and only dealer mechanics could fix your car. Lumber could only be sold to licensed contractors, toilet bowl floats could only be sold to licensed plumbers, etc, etc, all in the name of liability and protecting the consumer.

We as scuba divers should form a political action committee and start lobying the legislators to pass legislation to get the dive industry to sell the consumer parts, manuals, tools etc to follow the norm of every other industry in out country. Only then will this scuba industry policy change.

We as scuba divers should form a political action committee and start lobying the legislators to pass legislation to get the dive industry to sell the consumer parts, manuals, tools etc to follow the norm of every other industry in out country. Only then will this scuba industry policy change.

Similar threads

Trip Report

CAYMAN BRAC BEACH RESORT/REEF DIVERS

- Replies

- 50

- Views

- 4,169

- Replies

- 24

- Views

- 7,296

Trip Report

Raja Ampat 2 weeks at Cove Eco Resort

- Replies

- 22

- Views

- 3,057

- Replies

- 14

- Views

- 4,705

- Replies

- 38

- Views

- 9,359