Time for a new shop

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breathing wet and air leak during vacuum test for Aqualung Mikron ACD

- Thread starter jdevic

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Or to join the dark side and learn himself!Time for a new shop

wnissen

Contributor

Everyone makes mistakes, but that would be an absolute deal-breaker for me. When you're talking life-support, two strikes is more than enough and I would argue you have an obligation to your fellow divers to alert the management of the shop to what happened. I've heard that Mikrons are harder to work on, but a good shop will turn down work they can't complete.After I got home, I noticed that the primary (left) and octo (right) were slightly different...It seems he did not put the tube all the way for the primary...

Just a quick update, I've decided to try it myself...

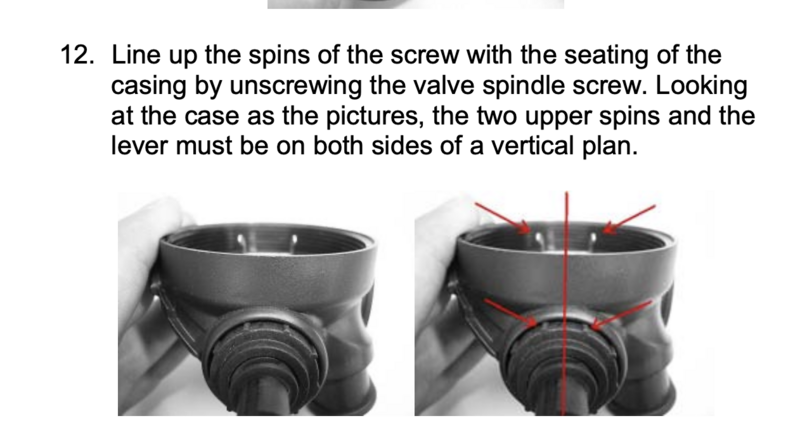

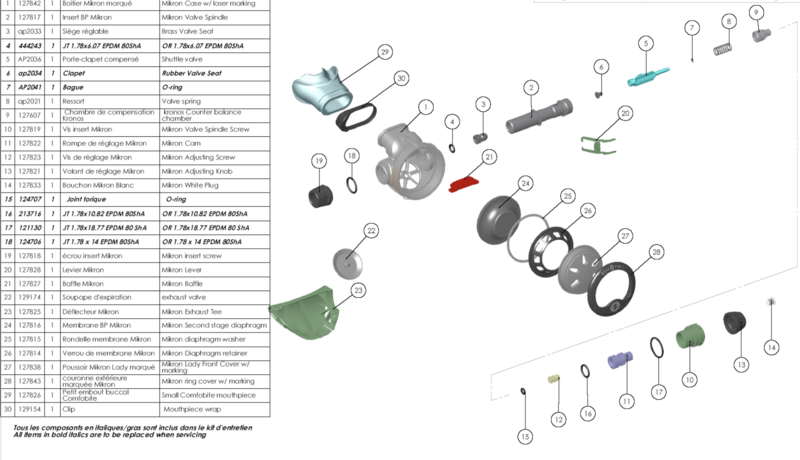

I removed the diaphragm and hose, then partially unscrewed the plastic pieces on both end (part #10 with the spins and #19) and repositioned the spins. It didn't go all the way in like the octo, just slightly behind the edge (the pic in the manual didn't go all the way either).

I put the diaphragm and cover back on, and this time it is sealing tight when inhaling.

I guess a success?

I don't have a tank to test at home. My only concern is that I may have messed up the cracking pressure.

I recall he set it at 140psi previously with the knob at max position (probably shouldn't have done that).

Accordingly to the manual, the cracking pressure appeared to be controlled by screw #12 and possible #3. I didn't touch either of those. I should be fine I guess?

I removed the diaphragm and hose, then partially unscrewed the plastic pieces on both end (part #10 with the spins and #19) and repositioned the spins. It didn't go all the way in like the octo, just slightly behind the edge (the pic in the manual didn't go all the way either).

I put the diaphragm and cover back on, and this time it is sealing tight when inhaling.

I guess a success?

I don't have a tank to test at home. My only concern is that I may have messed up the cracking pressure.

I recall he set it at 140psi previously with the knob at max position (probably shouldn't have done that).

Accordingly to the manual, the cracking pressure appeared to be controlled by screw #12 and possible #3. I didn't touch either of those. I should be fine I guess?

If I'm reading the diagram right, you shouldn't have effected the tune at all, only moved the entire air barrel assembly a tiny bit to the side. If anything it may crack a tad easier due to the levers contact point being more closely centered on the diaphragm.I don't have a tank to test at home. My only concern is that I may have messed up the cracking pressure.

But my advice is worth precisely what you paid for it!

Respectfully,

james

Thanks! I did end up adjusting #3 (the screw inside the hose end) for the lever position as per the manual, since it felt a bit loose after i moved the assembly. It has similar bounciness as the Octo now. I hope that won't impact cracking pressure much, since I didn't touch #12.If I'm reading the diagram right, you shouldn't have effected the tune at all, only moved the entire air barrel assembly a tiny bit to the side. If anything it may crack a tad easier due to the levers contact point being more closely centered on the diaphragm.

But my advice is worth precisely what you paid for it!

Respectfully,

james

Overall, feeling pretty good that it should no longer leak!

All my regs are unbalanced seconds (I'm cheap and can punch my own seats for them), but the lever sits a tad different under pressure.... I'm not sure if balanced seconds will do the same. Worst case, when you get it on a tank you have to re-adjust the orifice (part #3) a tad bit again.Thanks! I did end up adjusting #3 (the screw inside the hose end) for the lever position as per the manual, since it felt a bit loose after i moved the assembly. It has similar bounciness as the Octo now. I hope that won't impact cracking pressure much, since I didn't touch #12.

Look in the inside of the reg behind the diaphragm (yes, remove the diaphragm) at the place where the tube seats against the INSIDE of the housing. The side of the tube where the orifice goes into. If there is a gap in there (again the inside of the housing) you are not seated. If there is no gap you have done it properly!

If you look at the front of the reg, cracking force will be adjusted from the right side or the knob side. Lever height from the left or the hose side where the orifice screws into. It's a balancing game, you adjust one you may have to go to the other side and adjust the other. This is best done with an in-line adjustment tool...

If you look at the front of the reg, cracking force will be adjusted from the right side or the knob side. Lever height from the left or the hose side where the orifice screws into. It's a balancing game, you adjust one you may have to go to the other side and adjust the other. This is best done with an in-line adjustment tool...

Thanks very much, sir! I think now it is seated properly and no more gaps from inside. I also now get a complete seal when inhaling with 1st stage closed.Look in the inside of the reg behind the diaphragm (yes, remove the diaphragm) at the place where the tube seats against the INSIDE of the housing. The side of the tube where the orifice goes into. If there is a gap in there (again the inside of the housing) you are not seated. If there is no gap you have done it properly!

If you look at the front of the reg, cracking force will be adjusted from the right side or the knob side. Lever height from the left or the hose side where the orifice screws into. It's a balancing game, you adjust one you may have to go to the other side and adjust the other. This is best done with an in-line adjustment tool...

I will try to get the cracking force checked at the shop before I head to the Red Sea in 2 weeks if I have the time. That said, I noticed that the adjusting knob (from fully in to fully out) did make a big difference in terms of how bouncy the lever was, and it is behaving similarly as the well tuned octo. I am sure I will get an acceptable cracking force using the knob alone. Worst case, I will open it up again and do it myself when I am in Sharm

Thanks again!

Gone for diving

Contributor

A fairly good rule of thumb is,,,,Unfortunately, you're seeing the downsides of the "regular maintenance cycles" that are pushed for regulators. You took a working regulator in and got a...not correctly functioning regulator back. This is not uncommon.

If it not broke, don't fix it,

It always amazes me when I get a old regulator that's sat around for 10-20 years,

and usually nothing leaks and works fine,

I usually have a look at the second stage,

But if the first stage has no creep, I don't even disassemble it,

Similar threads

- Replies

- 17

- Views

- 1,741

- Replies

- 11

- Views

- 2,862

- Replies

- 2

- Views

- 1,320