I’m working on a home O2 boosting setup. I picked up the Usun XB30-OL and have the bits for a whip (minus filters) but wondering were the needle valve should be installed… right off the bottle of ABO or on the fill end near my 3L breather bottle?

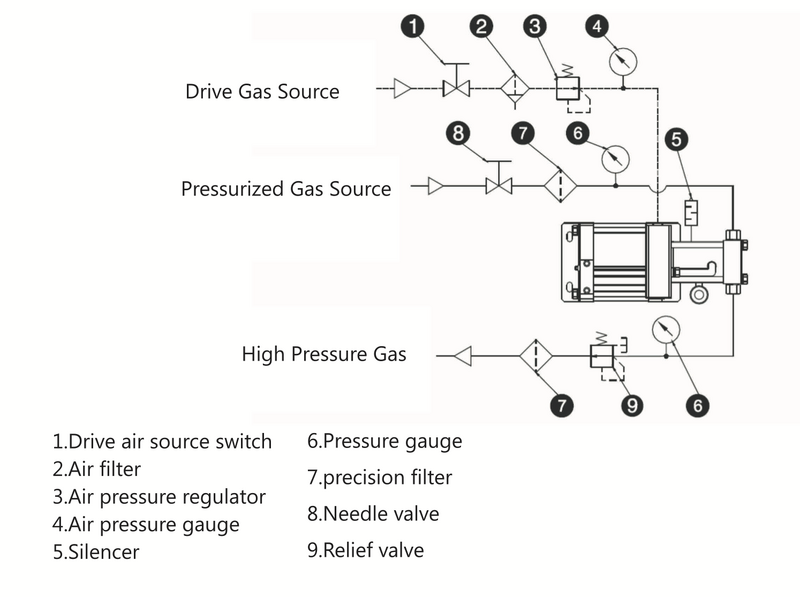

Usun shows the needle valve on the supply end, but the pre-made booster whips like the one from Dive Gear express have a control valve on the fill end.

Supply end makes sense to me. Allows precise control of the initial flow of gas through the lines and has my hand on the supply end to quickly shut things down should something happen.

They also show a filter on the supply and fill side… Don’t have either of those. Not sure how important they would be in a setup that never leaves the garage and the CGA fitting left in place to minimize contamination.

I'm new to CCR, new to O2 fills but have read everything I can get my hands on including Harlow's Hacker's Companion and spoke with my instructor.... Might be a silly question but want to make sure I minimize the odds of unexpected fireworks

Thanks in advance

Usun setup schematic:

Usun shows the needle valve on the supply end, but the pre-made booster whips like the one from Dive Gear express have a control valve on the fill end.

Supply end makes sense to me. Allows precise control of the initial flow of gas through the lines and has my hand on the supply end to quickly shut things down should something happen.

They also show a filter on the supply and fill side… Don’t have either of those. Not sure how important they would be in a setup that never leaves the garage and the CGA fitting left in place to minimize contamination.

I'm new to CCR, new to O2 fills but have read everything I can get my hands on including Harlow's Hacker's Companion and spoke with my instructor.... Might be a silly question but want to make sure I minimize the odds of unexpected fireworks

Thanks in advance

Usun setup schematic: