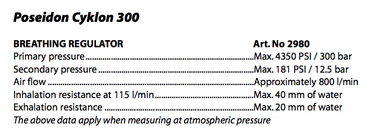

Even crazier -- originally, 181 psi and change . . .I’m sure the manufacturers tested the crap out of their regs to come up with their numbers.

Poseidon Cyklon had an IP of over 160

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Advantages of a high or low IP on 1st stage regulators?

- Thread starter L13

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 8,245

- Reaction score

- 7,039

- # of dives

- 2500 - 4999

For years and years and years and years, I thought the plastic shim things in Scubapro piston regs

was only there to protect the brass body from the stainless spring and the piston end, who knows

In the ocean the iron particles would wedge themselves between everything and rust and corrode

So I took out the shim or the shims because the stuff would get in between, and rust and corrode

Now all I get from the oean in a relatively short period of time with no shims is rust and corrosion

I thought, a shims width of pressure to increase or decrease the pressure from a spring that heavy

IP who cares

was only there to protect the brass body from the stainless spring and the piston end, who knows

In the ocean the iron particles would wedge themselves between everything and rust and corrode

So I took out the shim or the shims because the stuff would get in between, and rust and corrode

Now all I get from the oean in a relatively short period of time with no shims is rust and corrosion

I thought, a shims width of pressure to increase or decrease the pressure from a spring that heavy

IP who cares

admikar

Contributor

Just nitpicking, but it is the other way around. Less IP means bigger difference between HP and IP side which means harder seal. While you are correct that in balanced 1st stage IP is doing less push, rest of it is done by spring. In this case, less spring which makes IP push more forcefull.It is theoretically less wear and tear on the seat, because remember that IP is the force that closes the 1st stage valve by pushing the piston into the seat, so lower IP means less force on the piston.

halocline

Contributor

IP is the force that closes the piston, therefore with the same spring in place, lower IP means less force on the piston. That's just math. What you are referring to is the pressure gradient across the seal, which as you say is slightly higher given identical supply pressures with a lower IP. And I can understand how you might intuitively think that a larger pressure gradient means it takes more force to keep the seal closed, but that is not correct. If it were, then IP would be higher.Just nitpicking, but it is the other way around. Less IP means bigger difference between HP and IP side which means harder seal. While you are correct that in balanced 1st stage IP is doing less push, rest of it is done by spring. In this case, less spring which makes IP push more forcefull.

There is also the issue of 'seating force' which I guess would be the total force pushing the piston into the seat (IP X area of piston head) minus the force that the spring exerts on the piston in the opposite direction. I think that you are assuming that as the pressure gradient rises, so must the seating force, but that can't be true unless the IP were to also rise.

I'm describing this as all taking place in a balanced piston design, like the SP MK5/10/20 etc.

Similar threads

- Replies

- 7

- Views

- 814

- Replies

- 35

- Views

- 5,103

- Replies

- 12

- Views

- 1,129