You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A repository of 3D print STL sources

- Thread starter James79

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Another one of my little projects. I made a carrier to haul tanks around in my car. Just used it earlier today to take my tanks in to get VIP done.

Designed to mount to 60x20mm aluminum extrusion. Custom cut lengths from Misumi.

Nice work all around but damn all that looks expensive!! I'm over here splitting hairs about supports / no supports to save time and money (maybe .70?) and you're building $300 weights

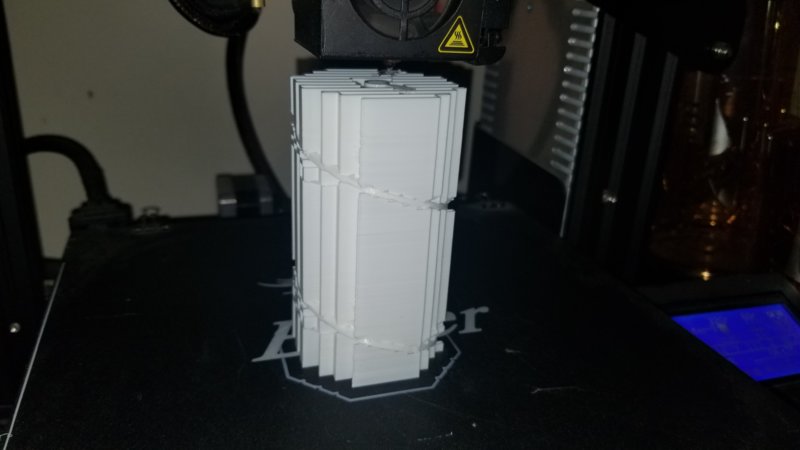

Anyway, I scrapped the first one as the spiral wasn't looking great at all without supports. I have another printing now with supports (only 10% infill)... it's looking pretty good. I talked to @James79 about maybe adding something to ve able to print without supports. So far though this thing is looking pretty great!!!

Here's what it looked like before I had to leave;

hotpocketdeath

Registered

Nice work all around but damn all that looks expensive!! I'm over here splitting hairs about supports / no supports to save time and money (maybe .70?) and you're building $300 weights

Anyway, I scrapped the first one as the spiral wasn't looking great at all without supports. I have another printing now with supports (only 10% infill)... it's looking pretty good. I talked to @James79 about maybe adding something to ve able to print without supports. So far though this thing is looking pretty great!!!

Ha, yeah, that was one of the reasons I backburnered the weight project was because of costs. Not really worth it to make it just for myself. But it was fun to design. The tank carrier wasn't too bad. Aluminum extrusion pre-cut to length was $27, About $10 worth of PETG to print the saddles (more perimeters and higher infill for strength). Like $2 or 3 in hardware to mount it together and like $30 for the 6-pack of straps that hold the tanks in place. I still need to print some endcaps to protect the ends of the extrusion, but that's pennies worth of material.

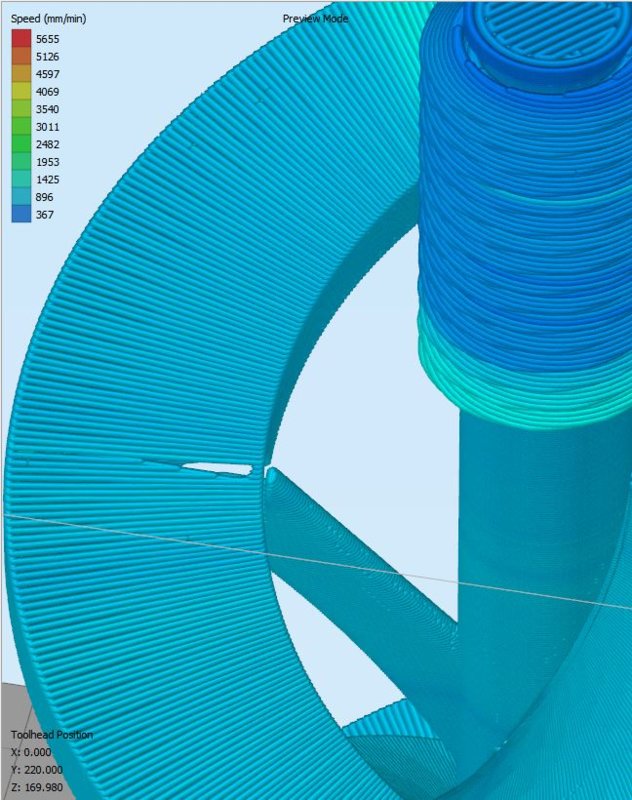

Now, some of my tricks for dealing with overhangs. When I design, I try to consider things like that and incorporate angles in ways to help reduce overhangs and bridges as much as possible. But if I do need to print overhangs here's what I do to help.

1. Increase the width of the outer perimeter. On a .4 nozzle, I've gone as high as .7 on my outer perimeter (this also helps when I do something in Vase mode)

2. decrease the layer height. Yeah, it will add time to the print, but I'm fine with that since my printer is stable enough I trust it to run unattended for long duration.

With a .6 outer perimeter and .15 layer height, Slic3r indicated almost no overhang printing when I loaded that model.

I usually take printer limitations (overhangs, etc.) into account when designing, but this was just a quick "rip an idea out" design. I'm throwing in some vanes that will add support (and turbulence, maybe)... will have the new design up for perusal shortly.Ha, yeah, that was one of the reasons I backburnered the weight project was because of costs. Not really worth it to make it just for myself. But it was fun to design. The tank carrier wasn't too bad. Aluminum extrusion pre-cut to length was $27, About $10 worth of PETG to print the saddles. Like $2 or 3 in hardware to mount it together and like $30 for the 6-pack of straps that hold the tanks in place. I still need to print some endcaps to protect the ends of the extrusion, but that's pennies worth of material.

Now, some of my tricks for dealing with overhangs. When I design, I try to consider things like that and incorporate angles in ways to help reduce overhangs and bridges as much as possible. But if I do need to print overhangs here's what I do to help.

1. Increase the width of the outer perimeter. On a .4 nozzle, I've gone as high as .7 on my outer perimeter (this also helps when I do something in Vase mode)

2. decrease the layer height. Yeah, it will add time to the print, but I'm fine with that since my printer is stable enough I trust it to run unattended for long duration.

With a .6 outer perimeter and .15 layer height, Slic3r indicated almost no overhang printing when I loaded that model.

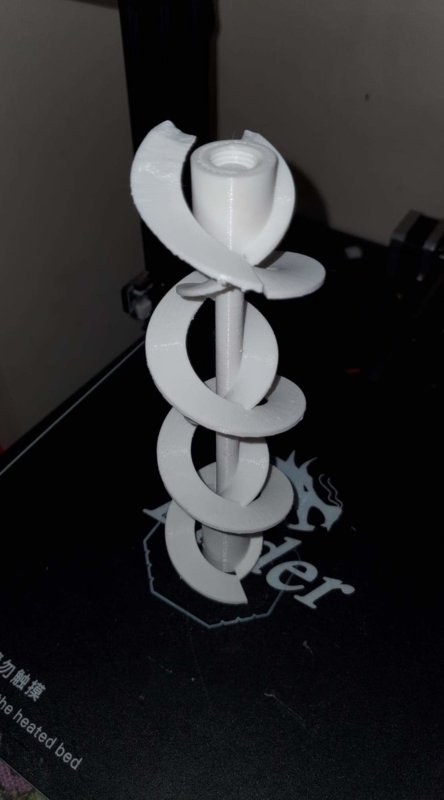

Well I am printing v2. Almost done;

Edit: I'll also add, my PLA probably has some moisture in it, this is an older roll I had laying around, so I expect it to have some flaws. I don't really care if it's going inside PVC. I do have some 2" PVC to stick it in when I get home.

Edit: I'll also add, my PLA probably has some moisture in it, this is an older roll I had laying around, so I expect it to have some flaws. I don't really care if it's going inside PVC. I do have some 2" PVC to stick it in when I get home.

Well, here's part A with support vanes added. But based on Rob's post above, and Hotpocketdeath's comments, I probably won't do the vanes for the rest of them.

Always open to constructive criticism,

James

I "think" that looks like it would print without supports. Would cut down a lot on material and time to print.

Ok, here she is. Removing the supports was no fun at all, took about 15-20 min, which is about 14 min longer than I like, but it screws into another perfect and has just the slightest gap in 2" PVC. Pretty great I think. The first picture is actually a part of one that I started to print (that I stopped to add supports) screwed to another.

Underneath is a little rough, but wouldn't effect functionality.

Excuse my dirty PVC, best I could find on hand.

Underneath is a little rough, but wouldn't effect functionality.

Excuse my dirty PVC, best I could find on hand.

Those damn air gaps are back

Similar threads

- Replies

- 0

- Views

- 1,926

- Replies

- 26

- Views

- 6,112

- Replies

- 20

- Views

- 5,031

- Replies

- 7

- Views

- 1,454