OTF

Coney Island Whitefish Biologist

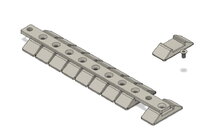

Yeah that thing can definitely be optimized to print nicely without supports. And supports waste a lot of material.

Not sure what's causing that gap - what software did you design it with? You could try analyzing/repairing the stl in something like meshmixer.

Not sure what's causing that gap - what software did you design it with? You could try analyzing/repairing the stl in something like meshmixer.