@Johnoly

I suspect the method used by me and many others in the genesis is a brighter red. So much of our equipment was adapted from existing items , home made (see "the Mask" ) or improvised

Originally all the valves were all 1/2 pipe thread , the O ring seal did not appear until Sportsways (Later Waterlung) introduced them to diving in the early 1960s.

The 1/2 valve required and very substantial vise to secure the tank in order remove the value

The components were a length of old well used fire hose an automobile and a Crescent wrench

The procedure was a follows

roll out the fire hose flat

lay the tank on the fire hose

fold the bitter end back over the tank

drive the automobile over the fire hose forming a wedged vise

Remove valve with Crescent wrench

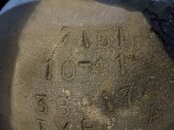

If required get out he metal stamp kit and hydro the tank

It should be noted the valves were seldom removed until John Gaffney and NASDS created the VIP Program in 1967- which was accidentally created when a SCUBA tank exploded and blew Bob Whitehead through a shop wall and broke his leg.

The valves were removed for the following reason;

When the valve were damaged

When the tank "swished" when shook = water in tank

When the tank rattled = rust in tank

When the tank was turned upside down the valve opened on a piece of paper and it became saturated with oil= bad fill from faulty compressor

And that wuzz the way it wuzzzz in the beginning of recreational diving,

Sam

Cc

@Scuba Lawyer -- bring back memories of days gone by ?