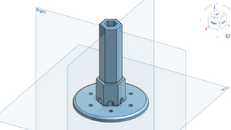

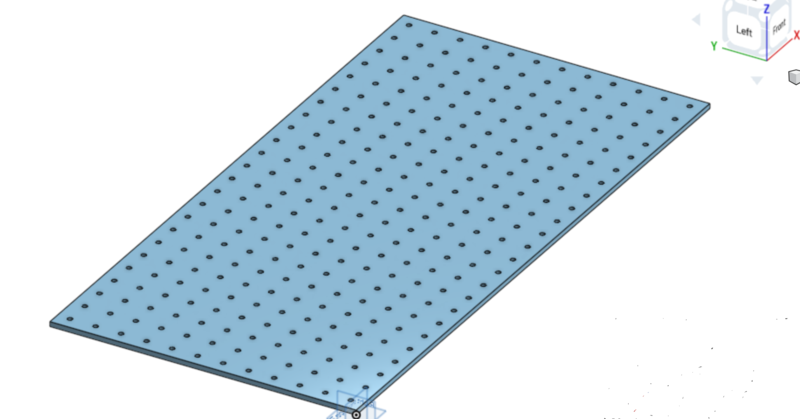

I have to say that I have finally been able to figure out how to use CAD: www.Onshape.com. I don't know if it's the best, but the learning curve was pretty easy for me and I picked up the basics one morning and was able to create the initial design of my battery holder. It's evolved quite a bit since but I wanted to add some hole that could not be done on the initial sketch. A friend of mine from the Gainesville Hackerspace walked me through it on our Slack channel last night and I was impressed. Yeah, it was a bit finicky, but that's been my life for a while.  He introduced me to patterns, first circular for my light and then encouraged me to go ahead and create the assembly table top I've been wanting to do. So, in less than fifteen minutes, I created a CAD file with 288 3/4" holes by simply creating one hole and then creating a pattern in two directions. Wow, that was simple.

He introduced me to patterns, first circular for my light and then encouraged me to go ahead and create the assembly table top I've been wanting to do. So, in less than fifteen minutes, I created a CAD file with 288 3/4" holes by simply creating one hole and then creating a pattern in two directions. Wow, that was simple.

So, what do you use? I want to find something that has dimensional lumber built in, rounded corners and all.

So, what do you use? I want to find something that has dimensional lumber built in, rounded corners and all.