I've now gone through three different oring sizes, both Duro 50 & 70, and experimented with nut tension to vary how far the lower oring is buried in the 2-104.

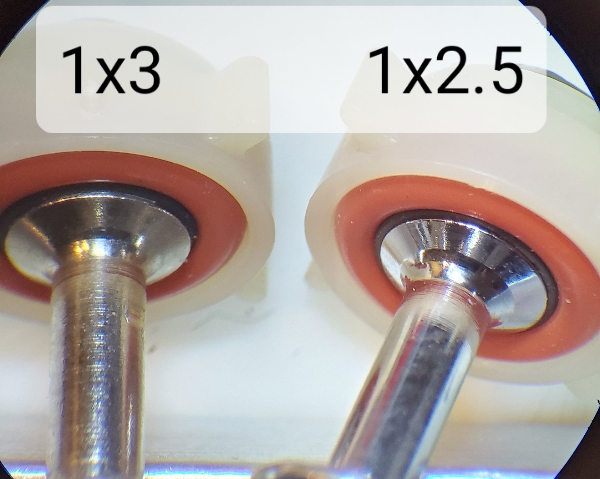

@Kupu was right - stretching the 1x2.5 over the shelf of the poppet stem seems to be slightly better than using my 1x3. As it turns out, I believe the leak is not between the 1x2.5 and the stem, but rather between the lower oring and the 2-104. From there, air easily slips inside the 104 and up into the cap. Using a 1x2.5 gives a better "nestle" inside the 104, altho it's subtle.

In any case, it's why nut tension was critical and poppet performance varied.

But my glued poppet has done well at all IP's, and I haven't had breakthru yet.

To put the poppet together, I used a room temperature vulcanizing (RTV) silicone sealant:

McMaster PN7545A451 ($7).

It starts to set up in about 5 minutes, so it helps to have a a magnifying glass and a brass pick to add the tiny amounts of sealant to the poppet stem with some dispatch.

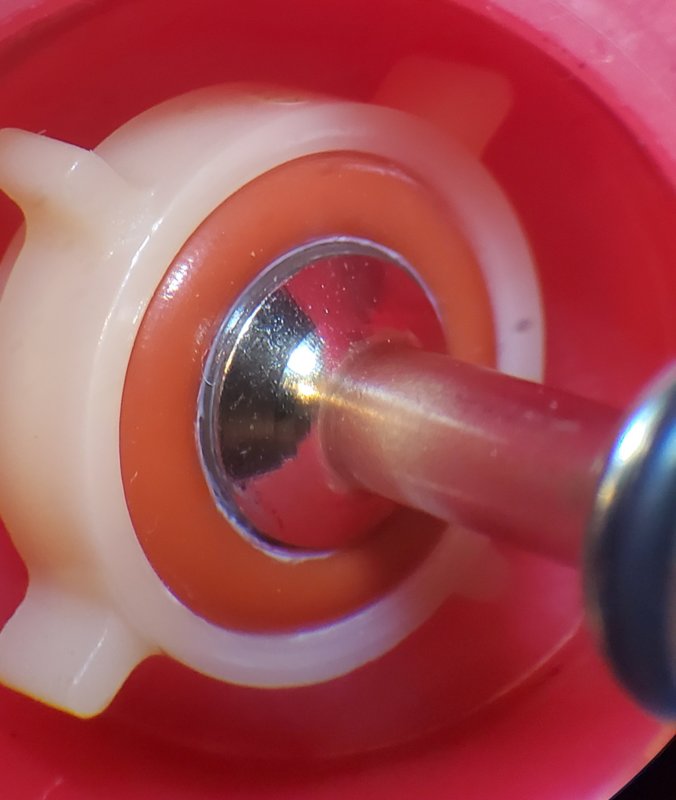

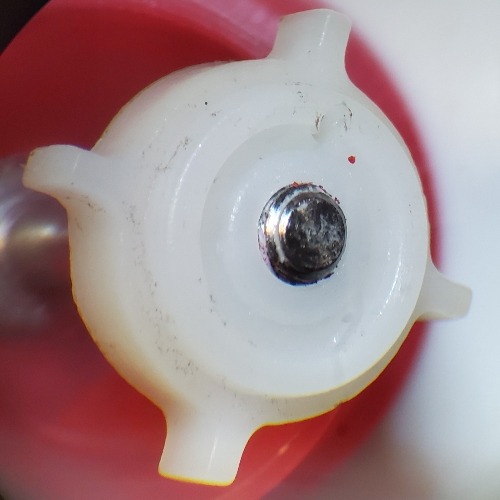

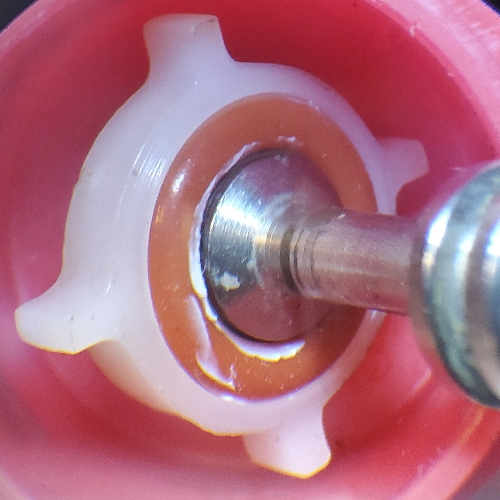

I start by adding the 1x2.5 to the poppet shaft, followed by a very tiny amount of sealant laid on with the tip of a sharp brass pick.

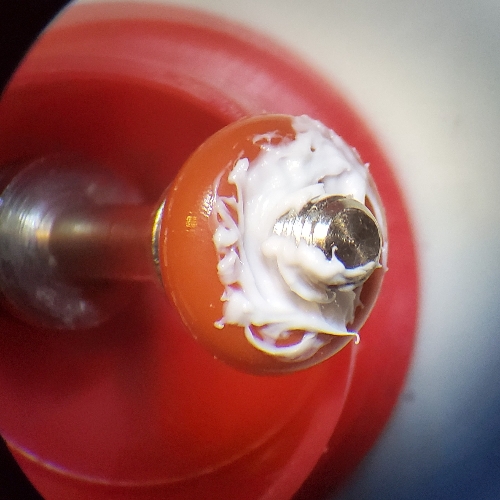

The 2-104 follows, and then a more generous layer of sealant that will fill the area under the cap.

I chose to add the second 1x2.5 dry, and then the cap.

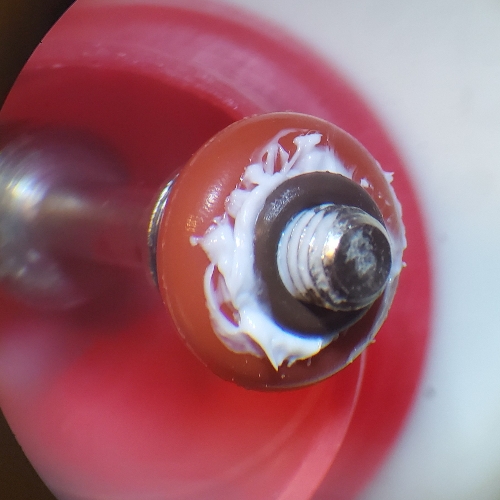

After screwing on the nut, about half the time a bit of sealant still leaks out under the first oring...

Since the sealant cures to harder than Duro 50, and is very adherent, you need to clean the surface of the oring immediately.

But with a little luck, you'll get all of your poppets. If the sealant starts to tack up before you get the cap on, you can bail and clean the metal stem, sacrificing three orings. Once the cap is on, you're committed.

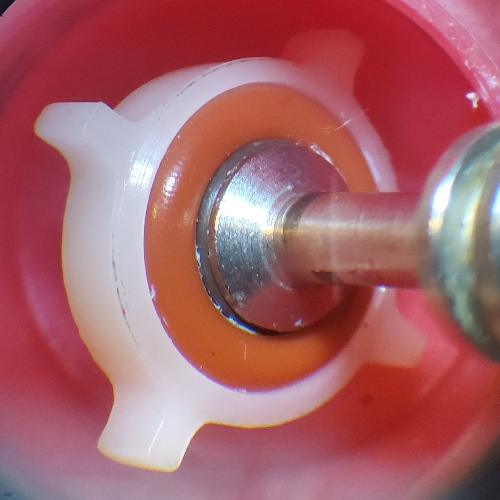

The nut should go on until a thread just starts to peek out the top. Just check to make sure the 2-104 isn't bulging very far out of the cap.

So far, it's held at all pressures, and easily seals at 0.55". As noted earlier, with this soft an oring, I couldn't get cracking effort higher than 1.4" at 135 psi IP, but who needs that?

I think @Kupu's found the solution to scarce D-series poppets!

@Kupu was right - stretching the 1x2.5 over the shelf of the poppet stem seems to be slightly better than using my 1x3. As it turns out, I believe the leak is not between the 1x2.5 and the stem, but rather between the lower oring and the 2-104. From there, air easily slips inside the 104 and up into the cap. Using a 1x2.5 gives a better "nestle" inside the 104, altho it's subtle.

In any case, it's why nut tension was critical and poppet performance varied.

But my glued poppet has done well at all IP's, and I haven't had breakthru yet.

To put the poppet together, I used a room temperature vulcanizing (RTV) silicone sealant:

McMaster PN7545A451 ($7).

It starts to set up in about 5 minutes, so it helps to have a a magnifying glass and a brass pick to add the tiny amounts of sealant to the poppet stem with some dispatch.

I start by adding the 1x2.5 to the poppet shaft, followed by a very tiny amount of sealant laid on with the tip of a sharp brass pick.

The 2-104 follows, and then a more generous layer of sealant that will fill the area under the cap.

I chose to add the second 1x2.5 dry, and then the cap.

After screwing on the nut, about half the time a bit of sealant still leaks out under the first oring...

Since the sealant cures to harder than Duro 50, and is very adherent, you need to clean the surface of the oring immediately.

But with a little luck, you'll get all of your poppets. If the sealant starts to tack up before you get the cap on, you can bail and clean the metal stem, sacrificing three orings. Once the cap is on, you're committed.

The nut should go on until a thread just starts to peek out the top. Just check to make sure the 2-104 isn't bulging very far out of the cap.

So far, it's held at all pressures, and easily seals at 0.55". As noted earlier, with this soft an oring, I couldn't get cracking effort higher than 1.4" at 135 psi IP, but who needs that?

I think @Kupu's found the solution to scarce D-series poppets!