You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Skipping 1st stage Maintenance?

- Thread starter Pearlman

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Not sure if plywood or plastic can hold the weight of the two gauges and last 20yrs or more without needing rework effort…

ABS plastic will last longer than you or I will and can be made plenty strong. It not like these things weigh more than a few pounds.

- Messages

- 8,546

- Reaction score

- 7,254

- # of dives

- 2500 - 4999

Everything should have its own articulating arm

www.googleadservices.com

www.googleadservices.com

Family too!

Desky Heavy Duty Ultrawide Monitor Arm

The Desky Heavy Duty Ultrawide Monitor Arm is designed to securely hold monitors up to 49 inches, including popular models like the Samsung Odyssey G9. Shop Now!

www.googleadservices.com

www.googleadservices.com

Family too!

And I dial the regs for optimal cracking pressure while in the water.

Second stages are tuned to have their lowest cracking effort when the adjustment is fully open. Dialing them in makes breathing effort worse. You would only dial them in if your second stage was starting to leak air to stop a free flow. Some Divers dial in their octopus to prevent the possibility of free flows in strong currents, but the reg in your mouth should be fully open.

I think most recreational divers misunderstand the purpose of the adjustment knob.

Second stages are tuned to have their lowest cracking effort when the adjustment is fully open. Dialing them in makes breathing effort worse. You would only dial them in if your second stage was starting to leak air to stop a free flow. Some Divers dial in their octopus to prevent the possibility of free flows in strong currents, but the reg in your mouth should be fully open.

I think most recreational divers misunderstand the purpose of the adjustment knob.

^^^^^^^ Most important advice concerning effort adjustment knob!!

In addition, the only other times I turn the knob in is when I am doing surface swims or water entry and the second stage isn't in my mouth to prevent free flow. When the second stage is in my mouth, the knob is all the way out for easiest breathing effort (except if there is air leak for any reason, then turn it in until the leak stops).

I purposely, for my personal regulators, will set the regulator to very, very, very slightly bubble (not free flow) with the knob fully out once the (new) seat has taken a set. I therefore will need to turn the knob in approximately a half turn to settle the seat in once broken in to stop the bubble. This does two things, acts as a seat saver (G250, 109, 156) and reduces cracking effort when fully out.

New gear hence experimenting with different settings in the first 50 dives with them … in practice I always discovered the fully open position as the best and rarely have to retune the adjustment knob after a few minutes of initial testing, except a few moments when facing strong currents… the flexibility is good to have.Second stages are tuned to have their lowest cracking effort when the adjustment is fully open. Dialing them in makes breathing effort worse. You would only dial them in if your second stage was starting to leak air to stop a free flow. Some Divers dial in their octopus to prevent the possibility of free flows in strong currents, but the reg in your mouth should be fully open.

I think most recreational divers misunderstand the purpose of the adjustment knob.

This is something I plan to do with my first service attempt this month. The S600 can be stored long term with a wooden stirrer (found in coffee shops) jammed in to depress the purge button just a bit but not the c370.I purposely, for my personal regulators, will set the regulator to very, very, very slightly bubble (not free flow) with the knob fully out once the (new) seat has taken a set. I therefore will need to turn the knob in approximately a half turn to settle the seat in once broken in to stop the bubble. This does two things, acts as a seat saver (G250, 109, 156) and reduces cracking effort when fully out.

New gear hence experimenting with different settings in the first 50 dives with them … in practice I always discovered the fully open position as the best and rarely have to retune the adjustment knob after a few minutes of initial testing, except a few moments when facing strong currents… the flexibility is good to have.

This is something I plan to do with my first service attempt this month. The S600 can be stored long term with a wooden stirrer (found in coffee shops) jammed in to depress the purge button just a bit but not the c370.

I will hook up an IP gauge and then make the final adjustment. I will charge the system and then shut the valve off. The IP gauge will fall slowly due to intentional leakage at the second stage orifice and then when I turn the knob in about a half turn or so the IP needle should stabilize. I charge the system again and with the knob turned in as previous there should be no leakage and the IP needle should sit at the set IP and when turned fully it out there should be a fall as the IP leaks off. If I need to adjust the orifice it is done in really tiny amounts like 1/32 to 1/16 turn. Regs with the Micro-adjust like the G260 the final adjustments can be made there, the SMs should give a neutral point for the MA initial setting. This all assumes your regulator system is otherwise leak free. Yes, in time the seat will continue to indent during use and even with the knob fully out as we have not removed all the tension, just most of it. Thereby increasing seat life during storage and allowing for very low effort in use, when needed, if needed.

You can never go wrong setting up per the SM. I have been told from a couple of knowledgeable sources that Scubapro thinks their plastic orifice and seats do not benefit greatly from a seat saver. Hmmm, dunno.

I guess as usually I have gone off track.

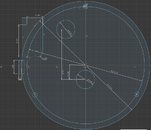

Since you guys were talking about magnehelic stands and the like.. i just more or less finished drawing up this thing.

I have not finished my first test print yet though, so i don't know if everything fits as i want it to. I'm also still missing some bolts for assembly.

But if you are interested i'd share the stl files before publishing the finished version on printables or something. Could also extract a drawing just for the magnehelic mounting holes and cutouts i guess.

(the screw holes are 120° from each other with the first starting at the middle on the top)

I have not finished my first test print yet though, so i don't know if everything fits as i want it to. I'm also still missing some bolts for assembly.

But if you are interested i'd share the stl files before publishing the finished version on printables or something. Could also extract a drawing just for the magnehelic mounting holes and cutouts i guess.

(the screw holes are 120° from each other with the first starting at the middle on the top)

Attachments

There you go: Desktop stand for Magnehelic and Manometer by Duglum | Download free STL model | Printables.com

And also some dxf files attached.

And also some dxf files attached.

Attachments

Similar threads

- Replies

- 29

- Views

- 2,612

- Replies

- 6

- Views

- 1,341