Zung

Contributor

I've had a few cases of IP creep, some bad and some mild.

A pretty bad case was reported here: it's a MK10 Plus (the "Plus" uses a different piston, seat and seat retainer), with a brass piston; I call it MK10Plus #1. After a full service and settling in, the IP crept to 170 PSI, with no shim. After much wrestling and with the help of all the gurus in general and akscubaduck1 in particular, I managed to downgrade it to straight MK10, and now it's working fine.

I also reported a milder case here, with a MK20 I call MK20 #2. After a full rebuild, IP was creeping to 140 PSI. I replaced the piston, et voilà, IP is now 129 PSI AND NO CREEP AT ALL!

So now I'm left with 1 MK10 Plus and 1 MK20 piston, and the thoughts of trying out mattboy's magic. Basically, the magic consists of:

Micro-Mesh is all over eBay, and the price is sensible: I've got 1 sheet of each grit for about $12 shipped. Just do a search with and without the dash.

Case 1: the guinea pig

So I have this MK10 Plus piston made of brass I don't care about, and I have another MK10 Plus body I call MK10Plus #3 that has a stainless steel piston and that guy creeps to 152 PSI. I'll try the #1 piston in the #3 body, so there's a flaw in the methodology because we're not comparing things that are directly comparable, and I'm too lazy to fit the #1 piston as is just to check.

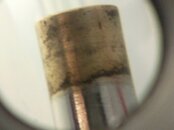

Anyway, the first 2 pics are "before". I took them with a 10x loupe held over the lens of my cell phone; it works better than my digital camera. There's a little thing in -01 that looks like a crack but it's just a lint.

Lap sanding is actually easier that I thought, the Micro-Mesh bites easily into the brass. I started with the 1500; it's a bit too coarse. I went through 1800, 2400, 3200, 3600, 4000, 6000, to 8000 and stopped there, checking often with the loupe. The whole operation took no more than maybe 15 min.

The next 2 pics are "after". The difference is huge.

So what gives? I don't know for sure yet, the thing is still settling; what I have so far:

Anyway, I'm VERY HAPPY with the mattmagic! Thank you mattboy!

A pretty bad case was reported here: it's a MK10 Plus (the "Plus" uses a different piston, seat and seat retainer), with a brass piston; I call it MK10Plus #1. After a full service and settling in, the IP crept to 170 PSI, with no shim. After much wrestling and with the help of all the gurus in general and akscubaduck1 in particular, I managed to downgrade it to straight MK10, and now it's working fine.

I also reported a milder case here, with a MK20 I call MK20 #2. After a full rebuild, IP was creeping to 140 PSI. I replaced the piston, et voilà, IP is now 129 PSI AND NO CREEP AT ALL!

So now I'm left with 1 MK10 Plus and 1 MK20 piston, and the thoughts of trying out mattboy's magic. Basically, the magic consists of:

- Inspecting the edge with a jeweler's loupe, 15x or more magnification prefered.

- Lap sanding the edge and the body with a magical ingredient called Micro-Mesh, with increasingly finer grit.

Micro-Mesh is all over eBay, and the price is sensible: I've got 1 sheet of each grit for about $12 shipped. Just do a search with and without the dash.

Case 1: the guinea pig

So I have this MK10 Plus piston made of brass I don't care about, and I have another MK10 Plus body I call MK10Plus #3 that has a stainless steel piston and that guy creeps to 152 PSI. I'll try the #1 piston in the #3 body, so there's a flaw in the methodology because we're not comparing things that are directly comparable, and I'm too lazy to fit the #1 piston as is just to check.

Anyway, the first 2 pics are "before". I took them with a 10x loupe held over the lens of my cell phone; it works better than my digital camera. There's a little thing in -01 that looks like a crack but it's just a lint.

Lap sanding is actually easier that I thought, the Micro-Mesh bites easily into the brass. I started with the 1500; it's a bit too coarse. I went through 1800, 2400, 3200, 3600, 4000, 6000, to 8000 and stopped there, checking often with the loupe. The whole operation took no more than maybe 15 min.

The next 2 pics are "after". The difference is huge.

So what gives? I don't know for sure yet, the thing is still settling; what I have so far:

- Pressure on: 9.5 bar /138 PSI

- 10 min. creep to 10.2 bar/148 PSI

- 1 hour later: after a (light) purge, swing to 8.5 bar/123 PSI, level off at 9.8 bar/142 PSI

- Purge again another hour later: 9.6 bar/139 PSI

Anyway, I'm VERY HAPPY with the mattmagic! Thank you mattboy!