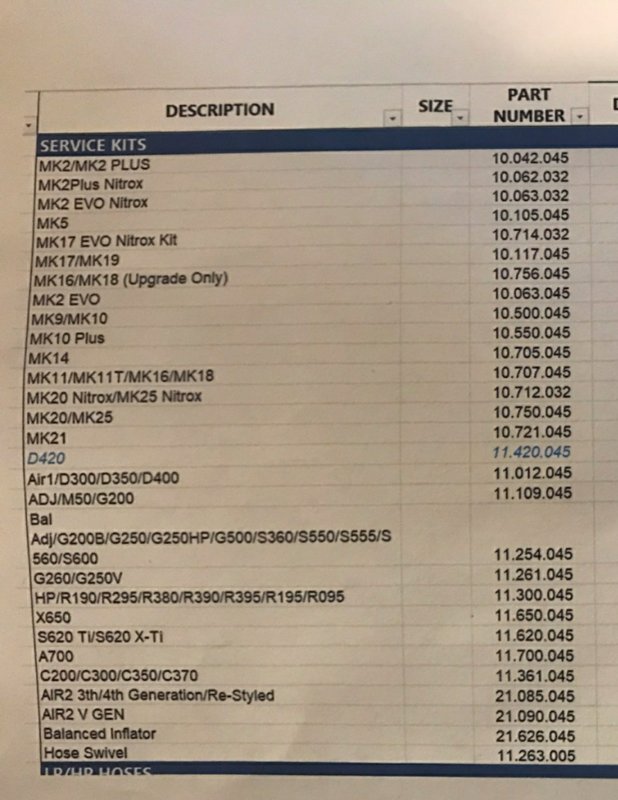

Yes, the Mk10 kit is on the 2020 Scubapro service kit list.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scubapro MK10 and HP Tanks

- Thread starter tdmp

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

tdmp

Contributor

- Messages

- 96

- Reaction score

- 50

My Mk 10s, primary regs for years and years start their dives at 4206.09439ish Psi

and are rarely fully serviced

View attachment 622375

Aren't they magnificent!

Sunn

Contributor

Standard service parts are available Sunn. New factory service kits were as of last year and may still be. Vintage Double Hose sells them.

The orings are all standard sizes and the seats are available from Trident distributors as well.

Sorry, I have to correct : what was refused by dealer and importer : servicing the 2nd stage (scubapro 109).

Rusty Shackleford

Contributor

Sorry, I have to correct : what was refused by dealer and importer : servicing the 2nd stage (scubapro 109).

Parts can be had for that. It can be converted to an s-wing poppet and serviced with a G-250 kit.

Or vintage double hose kits.

- Messages

- 8,245

- Reaction score

- 7,039

- # of dives

- 2500 - 4999

when I'll have time, I'll try to find everything to service it myself ! It was a beautiful companion.

Sunn, the good people on here will get you going any time you're ready "No Problemo"

Hey, @happy-diver, do you happen to know what HP piston shaft oring you or your shop uses? That's great to hear!

Now Mr rsingler I wish I had a story for you about my grandfather travelling through the swiss alps

with "Belle et Sébastien" during the war

but it's just a 90 duro EPDM oring and ashamed to say, if I don't have one of those a 90 something

I tried some urethane there once and they screeched my ears shut

I'm currently tinkering in stainless

I have two Mk10s that I use. Never a problem with my steel HP tank at 3400 psi. One has not been serviced in more than two years, hooked it up with no issues tonight out of curiosity, tank pressure was 3310.

servicing the 2nd stage (scubapro 109).

That's two o-rings and a simple puck seat found in a few SP second stages. Store | Vintage Double Hose or @buddhasummer could cobble that together for you.

It might be time to look for another dive shop.

halocline

Contributor

This is the second time I've had to rebuild my MK10 in 5 months. It slowly bubbles from the ambient pressure holes in the main body, which (I believe?) indicates leaking from the main body o-ring that seals around the piston. The piston shaft is corrosion-free. My MK10 is usually trouble-free and I'm trying to figure out what the issue is.

I have been using the first stage lately with HP tanks usually 3600-3700 psi for a fresh tank. I am wondering, can the MK10 handle this pressure or could this be causing the issue? I had actually converted the 1st stage to a MK10 plus years ago but had a lot of issues with IP creep so changed it back.

Any input would be helpful.

The MK10 is not great for HP tanks in my opinion. Mine work ok, but in general if I was using cave filled tanks to 3600 PSI regularly I would use my MK15 or 20. If you want to check how your MK10 is handling the pressure, there's a simple test. Hook it up to a tank at 3000 PSI, with a pressure gauge and an IP gauge attached. Open the valve and check the IP. Then put it on a tank filled to 3600, and check the IP again. If it's much higher, that piston shaft o-ring is extruding, and depending on the type of o-ring, this will quickly cause problems. You can actually do this test on one tank, just open/close the valve, tap the purge, and you can subject the reg to different pressures, checking the IP all along the way. This will give you a good idea of how your MK10 handles high pressure.

The best o-ring for that spot if you're going to use HP tanks is duro 90 polyurethane. But they can be a little trickier to install and they don't have good shelf life. The OEM SP kits have a duro 85 EPDM o-ring, which does not work as well for high pressure tanks.

But the bubbling out the ambient chamber may very well be something else. Getting the old o-ring out of that spot at service takes a lot of care and the right kind of o-ring pick. It's VERY easy for a careless tech to scratch the groove machined into the body of the reg where the o-ring sits. Bubbling out of the ambient chamber is a classic symptom of that. If that's the case, your reg is toast and whoever serviced it is responsible. Sorry, I hope that's not the case!

tdmp

Contributor

- Messages

- 96

- Reaction score

- 50

The MK10 is not great for HP tanks in my opinion. Mine work ok, but in general if I was using cave filled tanks to 3600 PSI regularly I would use my MK15 or 20. If you want to check how your MK10 is handling the pressure, there's a simple test. Hook it up to a tank at 3000 PSI, with a pressure gauge and an IP gauge attached. Open the valve and check the IP. Then put it on a tank filled to 3600, and check the IP again. If it's much higher, that piston shaft o-ring is extruding, and depending on the type of o-ring, this will quickly cause problems. You can actually do this test on one tank, just open/close the valve, tap the purge, and you can subject the reg to different pressures, checking the IP all along the way. This will give you a good idea of how your MK10 handles high pressure.

The best o-ring for that spot if you're going to use HP tanks is duro 90 polyurethane. But they can be a little trickier to install and they don't have good shelf life. The OEM SP kits have a duro 85 EPDM o-ring, which does not work as well for high pressure tanks.

But the bubbling out the ambient chamber may very well be something else. Getting the old o-ring out of that spot at service takes a lot of care and the right kind of o-ring pick. It's VERY easy for a careless tech to scratch the groove machined into the body of the reg where the o-ring sits. Bubbling out of the ambient chamber is a classic symptom of that. If that's the case, your reg is toast and whoever serviced it is responsible. Sorry, I hope that's not the case!

Thank you, I will give that a try. If that doesn't work, I will probably swap out a MK20 on my deco reg with this one for future use.

@tdmp I'm interested in your problem and I have a proposition for you. In anticipation of running into this same issue I purchased a few Teflon -010 & 017 hard seals (probably between duro 90-100) but I've not yet had any issues with my MK10s on HP tanks.

If you're in the US I'll be happy to send you a set of Teflon seals ( I'll throw in a couple of V90 -010 seals and I probably have some -010 PU 90 too) if you'll give us an update.

PM me with your snail mail address and I'll get them out to you.

Edit: You also have to promise not to kill yourself.

If you're in the US I'll be happy to send you a set of Teflon seals ( I'll throw in a couple of V90 -010 seals and I probably have some -010 PU 90 too) if you'll give us an update.

PM me with your snail mail address and I'll get them out to you.

Edit: You also have to promise not to kill yourself.

Similar threads

- Replies

- 3

- Views

- 446