phgachoud

Registered

Hey all!

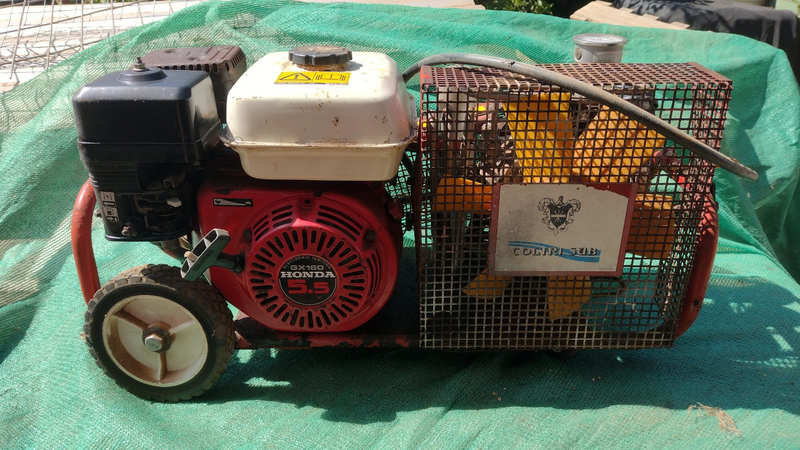

just acquired a year ~2000 coltri MCH-6 am wondering if you guys can help me building up for all people (and our children ) a list of does and dont with your own compressor! Maybe there are some stuff which are brand/model specific and others which are general. Beyond the famous RTFM, what do you guys advise?

) a list of does and dont with your own compressor! Maybe there are some stuff which are brand/model specific and others which are general. Beyond the famous RTFM, what do you guys advise?

Anything going through your head might be logical for some but not for others, so anything welcome!

Thx!!!

just acquired a year ~2000 coltri MCH-6 am wondering if you guys can help me building up for all people (and our children

Anything going through your head might be logical for some but not for others, so anything welcome!

Thx!!!