I don't know about these things. Once the piston land is scratched enough, does that mean you have to junk the reg? Or is something you can fix? Is it something that is naturally fixed as part of a normal service?

The art of restoring a piston first stage that's near and dear to your heart is not widely practiced. Most shops will (if your reg is new enough) simply replace the portion of your housing that contains your piston land (the area where the piston o-ring seals), and charge you an extra $50-80. In fact, most regs that have a LP leak (bubbling from the environmental holes that is not coming from the HP piston shaft o-ring) can be restored with a little loving care. The following photos show what I'm talking about. They're all piston lands from Mk 10's, 20's and Mk 25's that (since Scubapro doesn't do SPEC boots anymore) can't be sealed from what is floating around in the water. But I've even seen it in titanium Atomics that weren't sealed. I believe that titanium, though stronger, is not harder than chrome, and accumulated grit sticking to the back of the piston on the seawater side will do the same thing that you're seeing on these brass/chrome regs. These problems are slow-growing. Your reg won't fail in a week. But I still dive my sealed Mk 10 that is over 30 years old. If you don't religiously wash your reg, and don't seal it, don't be surprised at a leak at the 2-10 year mark, depending upon how gritty your dive water is. If your reg is out of production, then you're done.

This first photo shows the fine line (red arrow) where the piston o-ring sat for years. Accumulated behind it (blue arrow) is the result of salt/sand/mud that sat in place for probably a long time before I saw this reg.

While this reg was largely fixed by polishing as you'll see below, it never sealed perfectly.

What happens is that floating grit sticks to the Christolube used to lubricate the piston o-ring.

It gets worse. If you have grit that sits in place from a lack of thorough washing (and it's often impossible to get enough jet action to really wash out the environmental chamber of a piston), then that grit moves up and down (a little tiny bit) with the piston head every time you take a breath, and moves up and down (a lot) when you first pressurize the reg:

Those vertical scratches serve as air pathways for a low pressure leak.

But after polishing, you have a clean piston land that will probably seal perfectly, especially if you haven't gone through the chrome:

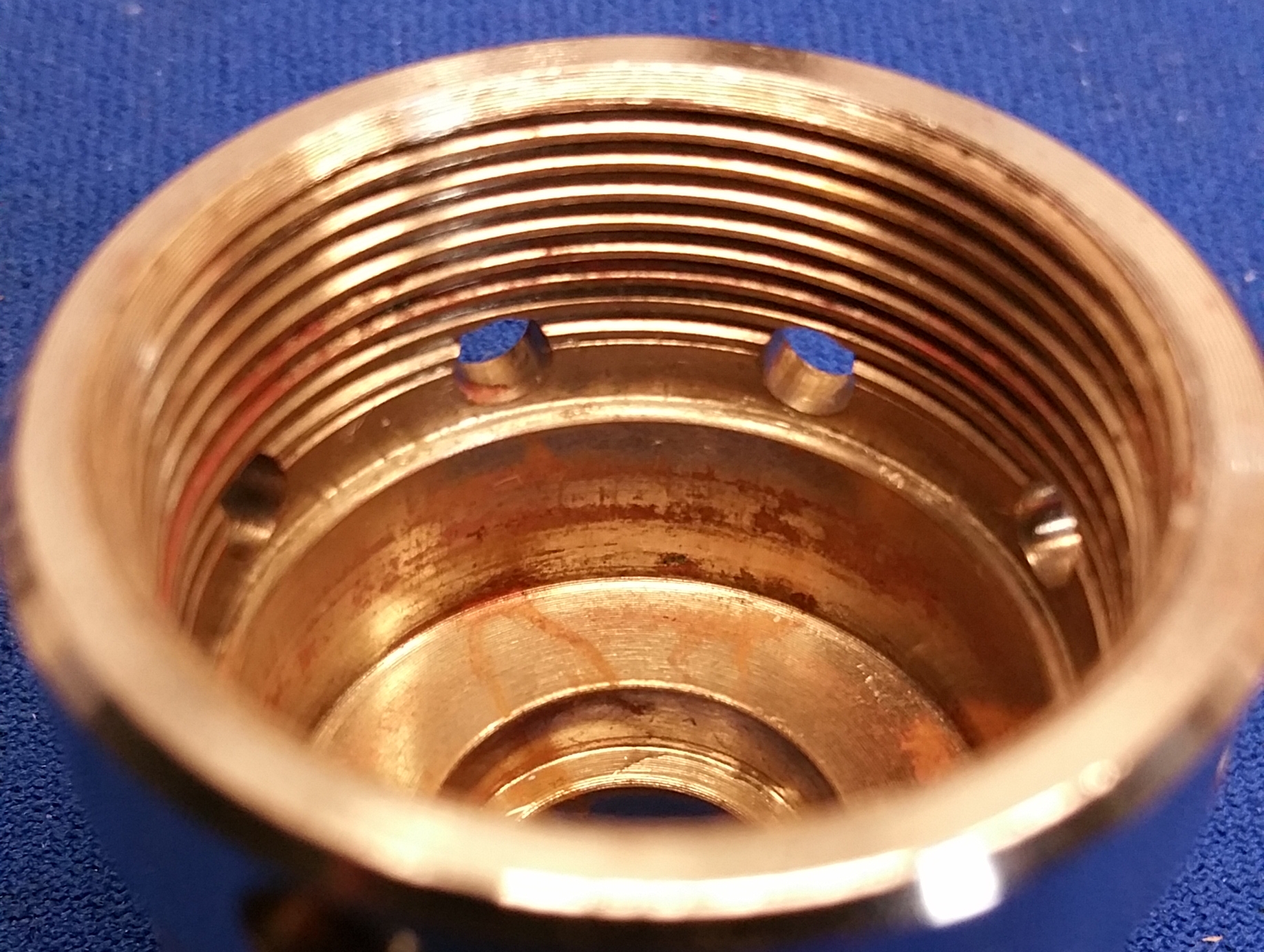

This series shows an old Mk20 that a diver wanted restored. As you can see from the golden color, much of the chrome is already gone.

After some time in warm ultrasonic solution, much of the crud is gone:

And after polishing, you can get a fair sealing surface back

But those tiny scratches are sources of microscopic leaks that will prevent true piston head seal. Tiny bubbles will appear in the ambient holes.

Micromesh is a cloth-backed sandpaper that ranges from 1,500 to 10,000 grit. Some techs use rouge and a cloth. Either way, you can gradually polish a leaking reg into pretty good shape. The more you have to polish, the more chrome you take off. But the point is, you can use an hour's hand labor to preserve your precious toy, rather than just switching out parts like most shops. For regs (Mk 5's, DACOR) with only rare spares, that's the only way you'll keep diving them.

View media item 204287

But the real point of my thread is that for my OWN regs, I've just stopped diving SP pistons that aren't sealed. I hand seal my old Mk10 with a DIY SPEC boot to keep sea water out, but mostly I just dive sealed Atomic pistons or a sealed diaphragm. I don't do it for ice or freezing. I do it for floating junk. And if you're a piston diver, it makes traveling easy. You only have to rinse OUT your second stage, and rinse OFF your first. Thirty seconds when you climb off the boat.

A side benefit is service. While second stages need some time in the ultrasonic every couple of years, I haven't serviced my Mk 10 in five years now. The IP is still 135, and locks up tight. The only thing that is inside is Christolube. Sea water pressure is transmitted to the back of the piston via the SPEC boot.