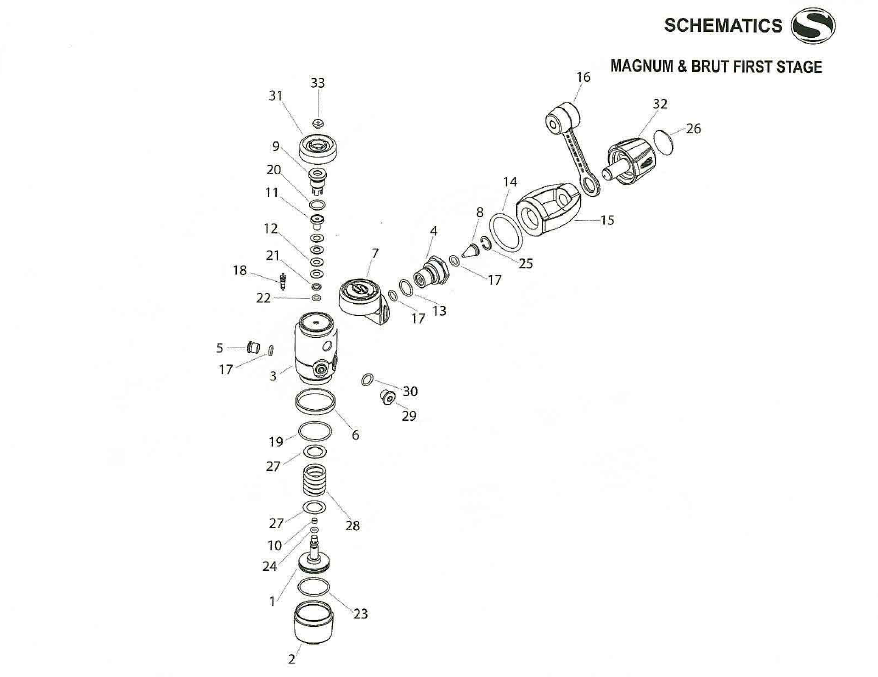

The Sherwood 9000-series is the second to last recent innovation by that firm. The SRB 9110 was part of the last Brut combo, for example:

It utilizes a unique sealed secondary DIAPHRAGM that senses sea water pressure to push on a simple old Schrader valve (Part #18)! Opening that valve adds HP gas to the IP chamber, compensating for increasing depth. The entire assembly is dry, and as @DA_Aquamaster noted, the HP knife edge uses Bellevue washers to respond to decreasing tank pressure. All VERY elegant. IMO, Sherwood's recent work has been singularly underrated. But out here on the Left Coast, we rarely see that brand. I bought one to tinker with, though. Very, very nice, and the Brut second stage is bullet proof.

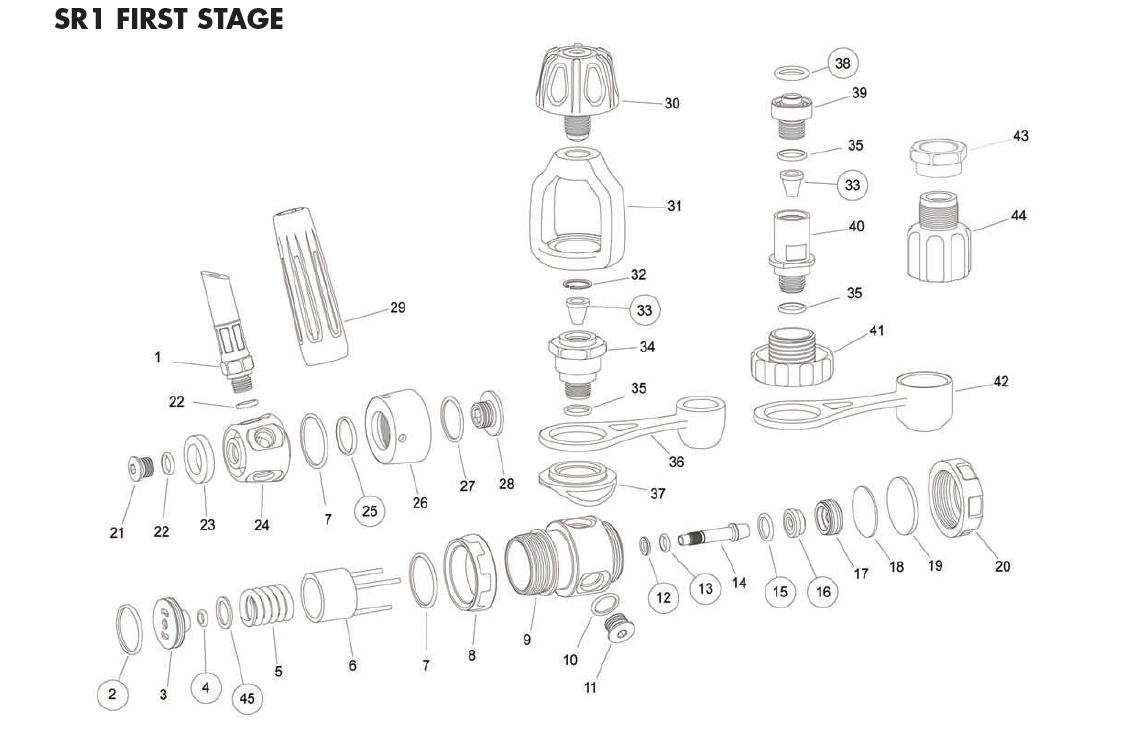

Your example, the SR2, is a reprise of a different concept for dry piston sealing which is similar to the old Beauchat V4. Beauchat used three metal rods linked to a screw-in plate to adjust piston IP on the fly, just like the hex-fitting on a diaphragm. Sherwood, on the other hand, uses similar rods that sit underneath another secondary sealed DIAPHRAGM to augment the spring force on the back of the piston to respond to increasing depth (part #6):

As Sherwood put it in their service seminar, these first stages are "diaphragm-piston" designs. Cute, but appropriate.

In the case of the SR1, a design flaw in tuning the second stage led to the SR2, but the basic concept is the same. The advantage of the SR1/2 is that the bore of the piston is HUGE, and the flow of this regulator is unsurpassed by anything from Atomic or Scubapro. The problem is that the legs that push against the back of the piston are part of a plastic molding that will not survive mistreatment. While it avoids the corrosion/binding problem that the Beauchat had, it won't survive any mistreatment by a tech. I don't know if they've moved from plastic to metal on those pushrods when the SR1 went to SR2. My Sherwood certification is not current.

Two good designs, but I'd defer to DA Aquamaster on usefulness for tech.

Lol, we've sure strayed from the OP's post regarding piston vs. diaphragm with this tec thread. Hijack!