So, Atomic sealed first stages use cristolube or something in the ambient chamber? And that lube separates the compressed gas from the sealing diaphragm, so the sealing diaphragm itself is not an O2 fire risk? But, for some reason, Atomic doesn't approve any of their 1st stages for use with more than 80% oxygen?

Almost,

@stuartv! There are two separate issues here - O2/fire risk and keeping a reg uncorroded.

Atomic piston fire risk: Atomic has only three potential fuel sources: 1) The two orings (one around the piston shaft, the upstream half of which sees HP O2, and the Piston O-ring, which only sees IP oxygen. 2) theoretically, the knife edge of the piston, and other reg parts which see impact HP O2. They use non-fuel (?EPDM?) for their o-rings, and DON'T use Titanium for their pistons or O2 reg. Monel for the high-O2 reg. piston, for example. Titanium as a fuel source is a bit of a reach, but is flammable like Magnesium. (There are more fuel sources that are the real culprits: oils and dirt that accumulate upstream and are impacted by 100% O2 when you open a valve quickly, but I'm assuming you know that and we are both starting with O2-cleaned equipment).

Atomic anti-corrosion resistance: The use of titanium was what brought Atomic to the forefront, and everyone else copied. ZERO sea water corrosion with titanium, but as you've heard me complain, it's anti-scratch resistance is less than chrome. Therefore, for

either ice protection or grit protection, filling the environmental chamber with Christolube keeps things under control, by eliminating sea water.

Now back to fire: As for 80% vs. 100% at 3000-4500 psi? That's a lawyer thing. Plenty of tec divers have been using brass/chrome regs with 100% O2 and EPDM or viton orings and Christolube or Tribolube without problems. The reason you hear the Mk2 touted is because it's so simple, and therefore has fewer o-rings that are exposed to HP O2. The Atomic M1 eliminates titanium, uses O2 compatible O-rings, and shields them from impact O2 wherever possible (e.g., the modification of their yoke bolt to put a groove for the HP o-ring land).

The Sherwood SR2 use a dry sealed chamber with some kind of diaphragm to seal it. Does that diaphragm pose any risk with respect to O2 compatibility?

Is there any dry sealed piston 1st stage made by anyone that is safe for O2 use?

Still wondering if the SR2 setup is any good. I appreciated

@rsingler's post, but it left open whether the SR2 has any/all of the SR1's issues fixed.

And is the 2nd stage any good? I can't even find whether the 2nd stage has a metal or plastic air tube.

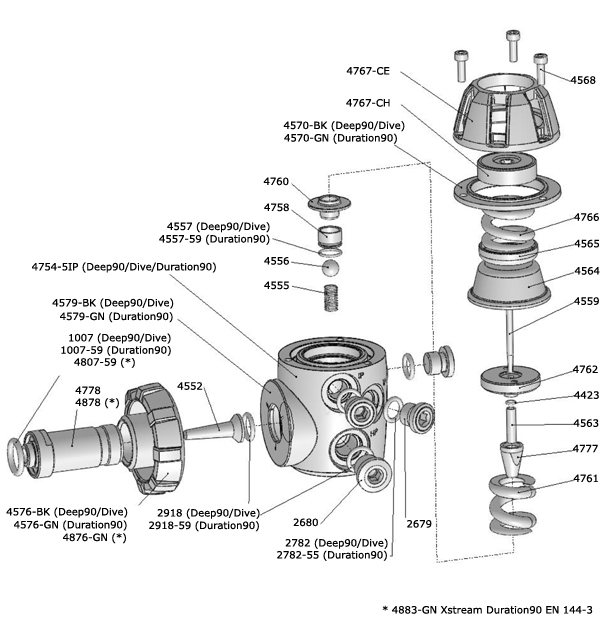

The Sherwood's "diaphragm" is a bit of a misnomer. Like the roof of the sealing ring on the Atomic piston, it's just a force transmitter. The diaphragm isn't exposed to O2 or air at all. It sits in the water (see diagram) and when increasing sea water pressure depresses it, pushes the stem of the Schrader valve a little until increasing IP forces the base of the piston back against it. So as with any other piston, the choice of o-rings will determine fire susceptibility. You'll have to consult with a tec guy that uses Sherwood to see if they modify it that way.

As for the second stage, the barrel is metal. A good design, and the SR1 problem was small and solved by a washer to prevent the tuning spring from catching, but not my favorite second. Very solid, though, with great WOB numbers.

View media item 204311

Again, you'd have to talk to the East Coast tec guys to see if anyone mods it for higher O2. It's only rated by Sherwood to 40%.