00wabbit

Contributor

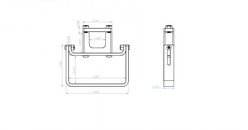

I will post the updated solidworks with renderings tonight. I will also make a simple general model of the light to put into the bracket so you can get a sense of scale.

I have a couple other ideas that might further reduce cost. I also have an idea that might make it fit lights of varying diameters. I will have to play with it a bit to see if it works.

I have a couple other ideas that might further reduce cost. I also have an idea that might make it fit lights of varying diameters. I will have to play with it a bit to see if it works.