You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is the DSS Thorus 25 Wing actually a horse shoe?!!!!

- Thread starter Wingman_

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 3,138

- Reaction score

- 4

SparticleBrane:If someone likes an STA-less wing without a zipper, get it from DSS. If you want a zipper and want to use an STA, get it from Patrick.

Makes sense to me!

cool_hardware52

Contributor

Stephen Ash:Cerich... I'll let you in on a secret...

The zipper in my Oxy Mach V appears to be exactly the same as the zipper in my DSS LCD... and my Agir and my OMS...

Note: I never said they weren't, I just asked what was used in a MachV. This is apparently a secret.

Tobin

cool_hardware52

Contributor

Stephen Ash:Well actually...

In my opinion, you responded to my post with "inflammatory questions."

Really? Which one?

Are you really suggesting that center panel 2+ inches wide is a distinct advantage over a 3.5 inch center panel?

Was it this one where I ask you to clarify?

Has this feature proven valuable? Have you needed to inspect or replace your MachV bladder? Are you aware of a lot of Mach V bladders that needed replacement in the field?

Or perhaps these two where I ask for numbers based on your experience?

Can you direct me to the DSS users (besides you) who are unhappy with our "STA-Less" approach?

Or maybe this one where again I ask for others that might support your position?

I did notice that you failed to answer any of them......

Tobin

SparticleBrane

Contributor

IMHO, having a zipper is a nice option. I have had to inspect bladders before (thankfully none were mine) and it was nice to be able to do it myself without having to send them back.

If it's the day before a dive trip and I find a pinhole leak in a bladder, or worse yet if it's on the boat before I hop in the water and someone manages to poke a hole in the bladder, it'd be nice to be able to fix it right there instead of having to send it back and perhaps sit out of diving because of such a small issue. To me, sewing a wing shut is akin to welding a car's hood shut. I should be able to change out and tinker with whatever I wish, since I paid for it. I shouldn't have to send it back to the manufacturer except for serious manufacturing defects.

I also personally like to use an STA but again that's just my opinion.

I also don't see this obsession with making wing so narrow. How much are you reducing drag by doing so? Am I going to be able to go another 4-5ft per kick cycle as a function of a much narrower wing? If not, what's the point? If you're holding your head up as you kick (ie in 'good trim') then you already have a big concrete block out in front that's creating drag.

The other thing that bothers me is the ridiculousness of what Patrick and Tobin are debating. How you mount a tank onto a bp/w setup isn't some huge life or death decision. It's just ridiculous to argue over that, and other such small things.

</rant>

If it's the day before a dive trip and I find a pinhole leak in a bladder, or worse yet if it's on the boat before I hop in the water and someone manages to poke a hole in the bladder, it'd be nice to be able to fix it right there instead of having to send it back and perhaps sit out of diving because of such a small issue. To me, sewing a wing shut is akin to welding a car's hood shut. I should be able to change out and tinker with whatever I wish, since I paid for it. I shouldn't have to send it back to the manufacturer except for serious manufacturing defects.

I also personally like to use an STA but again that's just my opinion.

I also don't see this obsession with making wing so narrow. How much are you reducing drag by doing so? Am I going to be able to go another 4-5ft per kick cycle as a function of a much narrower wing? If not, what's the point? If you're holding your head up as you kick (ie in 'good trim') then you already have a big concrete block out in front that's creating drag.

The other thing that bothers me is the ridiculousness of what Patrick and Tobin are debating. How you mount a tank onto a bp/w setup isn't some huge life or death decision. It's just ridiculous to argue over that, and other such small things.

</rant>

cool_hardware52

Contributor

SparticleBrane:I also don't see this obsession with making wing so narrow. How much are you reducing drag by doing so? Am I going to be able to go another 4-5ft per kick cycle as a function of a much narrower wing? If not, what's the point? If you're holding your head up as you kick (ie in 'good trim') then you already have a big concrete block out in front that's creating drag.

I do think we have entered the realm of diminishing returns. You see it in all industries. There will be period of genuine rapid development and innovation. This is almost always followed by much less rapid innovation, but ever increasing marketing shrillness about smaller and smaller differences in competing goods.

My favorite example is beer. We have now seen various beers marketed based on the shape of the container it's sold in.

There may well be major innovations in wings that haven't been brought to market yet, but I'd guess the "low hanging fruit" has been picked already.

Having said that, narrow wings offer less drag. SB, we haven't met so maybe you are the exception, but my head's not as wide as my tanks and wings. (maybe things are different for you

Narrow wings are also easier to vent. That was the key reason we built the 3" center panel wings 3 years ago. It's all about tank wrap. The top arc of a wing is held down by the tank valve and first stage, and the side pontoons wrap the tank.

In a wide center panel wing that puts air in the wing in two bubbles that are well above the center line of the tank (assuming good horizontal trim) There will be no air in the top arc, and no air in the bottom connection of a donut wing.

To move air across the top arc of a wide wing the diver needs to go heads up feet down, or in the case of a donut he needs to go butt up, heads down.

If on the other hand you have a very narrow center panel wing the air in the two pontoons will be just slightly higher than the top arc of the wing. That allows moving air from side to side with very little change in trim, just a rise of the shoulder is all it takes, usually no more than is required to vent a Dry Suit.

If you doubt me talk to anybody that's used a doubles wing with a single tank. That's a somewhat exaggerated version of the wide center panel wing, taco city, very hard to vent.

SparticleBrane:The other thing that bothers me is the ridiculousness of what Patrick and Tobin are debating. How you mount a tank onto a bp/w setup isn't some huge life or death decision.

I agree completely. There are a number of valid means of doing so. I've often listed the pro's and con's of each. I certainly don't fear people using STA's. You can do so with our goods if you choose, although they are not required.

I will continue to respond when I see false information about our goods, and when I'm accused of lying or deceiving my customers. That sort of thing cannot stand unanswered in a Public forum.

Tobin

SparticleBrane

Contributor

I DO have a big head.cool_hardware52:Having said that, narrow wings offer less drag. SB, we haven't met so maybe you are the exception, but my head's not as wide as my tanks and wings. (maybe things are different for you)

Tobin

*Floater*

Contributor

SparticleBrane:I also don't see this obsession with making wing so narrow. How much are you reducing drag by doing so? Am I going to be able to go another 4-5ft per kick cycle as a function of a much narrower wing? If not, what's the point? If you're holding your head up as you kick (ie in 'good trim') then you already have a big concrete block out in front that's creating drag.

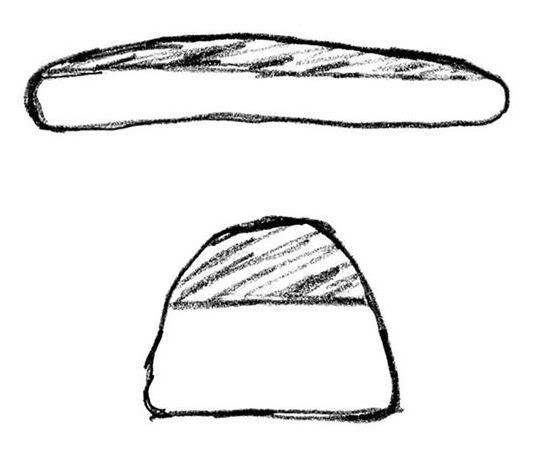

I agree with Tobin and here's an imagine to go along with what I think he's saying. The two pics below repesent the side profiles of two wings of roughly equal volume when wrapped up against the tank while the diver is in horizontal trim; one is long and narrow, the other is short and wide.

The shaded region represents the air bubble inside the wing. Now if you want to shift the air bubble to the front to balance out the wing, then which wing would make this easier? Which wing would require you to tilt less? Anyway, I like narrow wings, but to each his own, and I'm sure a wing can even be too narrow, for example, making it hard to trap gas onto one side.

P.S. Sorry about the ugly, exaggerated pics, but I think they make the point. And for the record, I think both DSS and Oxycheq make great wings.

Patrick

Contributor

PART #1

Yes, we'll see if we can get some testing done in a wind tunnel. Not a problem for me. I am sure I will win. The zipper on the top results in a broader front profile. When the zipper is in the inside, the front profile has a better cutting edge. I would compare the 30# Mach V to your LDS 30#.

Because it is a waste of time to do it and apparently only people with little or no diving experience are the only ones that seem to have difficulty understanding why.

I thought we already beat that issue to death, but you want to bring it up again. Go read my previous posts, my views remain the same.

Is this an admission to problems with your design?

I would agree that most divers send the wing to the shop or the mfg for replacement. For pin holes, most divers fix that themselves. More divers will get pin holes than requiring a complete bladder replacement. The user can fix a pin hole, but they need access to the bladder to do so.

Do you agree that the user should be able to fix a pin hole? Do you agree that fixing a pin hole is easy?

It is not difficult and that is why water bed mfgs sell patch kits. Nobody sends the bed back for repair and for pin holes nobody should be sending a wing back ---- unless they have no access to the inner bladder.

Yes, that is pretty accurate for me using 25 mil and not the inferior 22 mil. For the amount you have sent out and already had returns on, your return rate is higher. The Sig Series bladder is 10% thicker than your bladder. Maybe that is why your percent of return is higher than mine.

Your precent is higher than that already and your bladder is not as thick, so you have higher risk. As I stated, I am happy to see you go in that direction. You should use your own return numbers and not mine. However, I see it would be easier to make an argument if you were using my numbers.

I cannot think of one person who, if they can make a simple repair, would prefer to send it back to the mfg. If there are some, the population is very low.

I prefer not to get any experience at all in the area of repair. I wish you luck in continuing to get experience in that area.

Yes, I am in Florida and moving soon to a 16,000+ sf facility in January. My mfg is in CA and does have some operations in Mexico. You seem to bring the Mexico thing up quite a bit. Well, that is where most of the skilled labor is now for that type of work. The first industries we gave up in mfg was sewing --- shoes, clothing, etc. As I mentioned in previous posts with you, the Far East is where everyone is now going and you know it. Only small runs will be done over here.

One thing that is important is where the materials are made. Is your outer shell material made in the US, Korea or Taiwan? In my case, the materials are all made in the US. The material is more expensive, but the quality is significantly higher.

Also, I have 8.5 ounces of urethane on the inside of the outer shell. Most 1650 only has 2.5 or 3 ounces of urethane under it. What do you have?

I could care less where the wing is being sub assembled or sewn as long as I am getting the quality that I want.

I imagine you still have one guy sewing your wings and he told me he was born in South America. He has also not been sewing for the amount of time that the people are making my products. I go where the talent is.

Where has inability to sew had an impact on my designs? Not being able to sew has not stopped me from making a 360 loop wing with a 360 zipper. I pay people to do that work. Who give's a rat's ***?

It is not the same task. It is more difficult and I have said that in previous discussions on this list. And yes, the sewing must be spot on or you will have major difficulties. Again, I have a great mfg. making my products.

Not quite sure what point you are trying to make other than my mfg can do it and you have difficulties doing it and don't.

Those conversations came up when you were stating you saw no advantages in 360 loop wings. I guess you saw the light.

If you already knew something about zippers (not to be confused with knowing how to install one on a 360 wing), why ask the question?

Like I said, I am glad you are headed in that direction. Don't use my percentage of returns, use your own. It is like comparing apples and oranges.

I would not use a long, lightweight zipper on a wing and do not. Who do you know that does? If you do not know of anyone, why would you go out of your way to ask that specific question? I already know why, but am sure some people on the list do not.

By the way, all of my wings have used and still do use YKK 10 zippers. So, I am using the same top of the line zipper you claim to use. It is not lightweight, it is the same quality zipper.

I believe you wanted to imply that I used an inferior zipper and it blew up in your face. That reminds me of the thread where you thought I was using the same bladder for different wings ---- only to find out that I had matching bladders for every wing and YOU did not. You crack me up. Hopefully, others can see what I see.

Patrick

----

OxyCheq

http://oxycheq.com

cool_hardware52:Claims are one thing. Can you back it up? How do you define the "class" the MachV is in. Is it based on lift? If is is based on lift you need to qualify how that lift was measured. Was it measured in the free state, or assembled and ready for use? Tobin

Yes, we'll see if we can get some testing done in a wind tunnel. Not a problem for me. I am sure I will win. The zipper on the top results in a broader front profile. When the zipper is in the inside, the front profile has a better cutting edge. I would compare the 30# Mach V to your LDS 30#.

cool_hardware52:Anything less is apples to oranges, and is apparently something you are unwilling to do. Why again are you unwilling to provide capacity information in the assembled condition?Tobin

Because it is a waste of time to do it and apparently only people with little or no diving experience are the only ones that seem to have difficulty understanding why.

I thought we already beat that issue to death, but you want to bring it up again. Go read my previous posts, my views remain the same.

cool_hardware52:So you take pleasure in the troubles of others?

Is this an admission to problems with your design?

cool_hardware52:So you agree that most wings are returned if the bladder needs replacement? You do agree that bladder replacement is not often done in the field?

I would agree that most divers send the wing to the shop or the mfg for replacement. For pin holes, most divers fix that themselves. More divers will get pin holes than requiring a complete bladder replacement. The user can fix a pin hole, but they need access to the bladder to do so.

Do you agree that the user should be able to fix a pin hole? Do you agree that fixing a pin hole is easy?

It is not difficult and that is why water bed mfgs sell patch kits. Nobody sends the bed back for repair and for pin holes nobody should be sending a wing back ---- unless they have no access to the inner bladder.

cool_hardware52:So in your experience using a heavy gage urethane bladder in multiple 1000's of wings over a three year period has resulted in only 6 known failures of all kinds, and that having a zipper prevented 5 from being returned. Do I understand you correctly?

Yes, that is pretty accurate for me using 25 mil and not the inferior 22 mil. For the amount you have sent out and already had returns on, your return rate is higher. The Sig Series bladder is 10% thicker than your bladder. Maybe that is why your percent of return is higher than mine.

cool_hardware52:5 out of say 3000, that's 0.167% That's a risk I'm willing to take.

Your precent is higher than that already and your bladder is not as thick, so you have higher risk. As I stated, I am happy to see you go in that direction. You should use your own return numbers and not mine. However, I see it would be easier to make an argument if you were using my numbers.

cool_hardware52:This is a viable option for us, and our customers, because we can turn around the repair promptly.

The fact remains that many users, maybe even most, don't want to do their own repairs. The goods often are returned even when it might be repaired in the field.

I cannot think of one person who, if they can make a simple repair, would prefer to send it back to the mfg. If there are some, the population is very low.

cool_hardware52:I know full well how we do repairs, right here, right now. You are still in Florida right? and your fabricator has facilities in CA and Mexico. Doesn't that require shipping the goods coast to coast twice?

I prefer not to get any experience at all in the area of repair. I wish you luck in continuing to get experience in that area.

Yes, I am in Florida and moving soon to a 16,000+ sf facility in January. My mfg is in CA and does have some operations in Mexico. You seem to bring the Mexico thing up quite a bit. Well, that is where most of the skilled labor is now for that type of work. The first industries we gave up in mfg was sewing --- shoes, clothing, etc. As I mentioned in previous posts with you, the Far East is where everyone is now going and you know it. Only small runs will be done over here.

One thing that is important is where the materials are made. Is your outer shell material made in the US, Korea or Taiwan? In my case, the materials are all made in the US. The material is more expensive, but the quality is significantly higher.

Also, I have 8.5 ounces of urethane on the inside of the outer shell. Most 1650 only has 2.5 or 3 ounces of urethane under it. What do you have?

I could care less where the wing is being sub assembled or sewn as long as I am getting the quality that I want.

I imagine you still have one guy sewing your wings and he told me he was born in South America. He has also not been sewing for the amount of time that the people are making my products. I go where the talent is.

cool_hardware52:you have already stated that you don't sew.

Where has inability to sew had an impact on my designs? Not being able to sew has not stopped me from making a 360 loop wing with a 360 zipper. I pay people to do that work. Who give's a rat's ***?

cool_hardware52:I really doubt anyone that has actually installed a zipper would claim installation of a short zipper with bottom and top stops and a 360 degree seperating zipper are the same task.

It is not the same task. It is more difficult and I have said that in previous discussions on this list. And yes, the sewing must be spot on or you will have major difficulties. Again, I have a great mfg. making my products.

Not quite sure what point you are trying to make other than my mfg can do it and you have difficulties doing it and don't.

Those conversations came up when you were stating you saw no advantages in 360 loop wings. I guess you saw the light.

cool_hardware52:How convenient. In the world of zippers there really are only a few players. YKK is leader. The # 10 Molded Vislon zipper is the toughest thing available. All you have to do is look at the zipper pull. If it says YKK 10 you have the best. If it says YKK 8 or YKK 5 or YKK 3 etc it's a lighter weight zipper.

If you already knew something about zippers (not to be confused with knowing how to install one on a 360 wing), why ask the question?

cool_hardware52:Why would I want to put in a long, lightweight zipper just to reduce a 0.167% return rate.

Like I said, I am glad you are headed in that direction. Don't use my percentage of returns, use your own. It is like comparing apples and oranges.

I would not use a long, lightweight zipper on a wing and do not. Who do you know that does? If you do not know of anyone, why would you go out of your way to ask that specific question? I already know why, but am sure some people on the list do not.

By the way, all of my wings have used and still do use YKK 10 zippers. So, I am using the same top of the line zipper you claim to use. It is not lightweight, it is the same quality zipper.

I believe you wanted to imply that I used an inferior zipper and it blew up in your face. That reminds me of the thread where you thought I was using the same bladder for different wings ---- only to find out that I had matching bladders for every wing and YOU did not. You crack me up. Hopefully, others can see what I see.

Patrick

----

OxyCheq

http://oxycheq.com

Patrick

Contributor

cool_hardware52:Instead of implying that I'm lying you need to try and understand the geometry. I never said 1-2 inches wider than the 3 inches we currently use would have no impact.Tobin

You have the act of implying down to an art form.

cool_hardware52:There is useable volume in the space between the tank and the backplate that is left vacant with wide center panel wings. Wings that have center panels 6-7-8 wide fail to utilize this volume. By making reducing the width of the center panel on our LCD wings to just over 3 inches wide we took full advantage of this unused space. Narrower than 3 inches gains almost no lift, and eliminates the ablility to use our direct mount "STA-Less" design.Tobin

Personally, I prefer a metal STA that will never wear out and will be much more secure than plastic.

There is no extra space between the plate and the wing on the Mach V.

cool_hardware52:When you start to get much wider than 3 inches you do impact the lift. Look at tank assembled to a back plate from the top. Tobin

zzzzzzzzzzzzzzzzz.

You are putting me to sleep. As I stated in previous threads, this is not rocket science, but you like to make it sound like it is.

cool_hardware52:There a long list of things that only DSS does. Hose Hats, Bottom Timer Mounts, Compass Mounts, Hydration Bags, Low profile OPV's, Tail weight Pouches, Over molded grommets in our Backplates, 5 Sizes of back plate, bolt on weight plates, wedge blocks, rubber pull tabs, etc. etc. etc. Are all these "not a good Idea"?

The Hydration bags can be found at WalMart for about $5 and they work quite well. they come in a blue and gray box and are made by Cyclone. They are 2 liter Hydration Bladders and are used by the bicylce crowd. Anyone can find those in the bicycle or camping section at any WalMart.

But, this discussion is on zipper and zipplerless wings and I will stick to the subject.

cool_hardware52:I prefer not to do what everybody else is doing, plan on keeping it that way too.

Well, in earlier posts, you saw no reason or benefit for 360 loop wings and now have some. I imagine at some point you will figure out how to add a zipper and come around to that as well.

cool_hardware52:What diver would benefit from a wider and higher drag wing, or is this information top secret also?

That question kind of sums up what I think of your diving experience and lack of knowledge of products that came out on the market as recent as a couple of years ago.

cool_hardware52:Nothing I've said in this thread had anything to do with doubles wings.

You mentioned low profile wings, I had both singles and doubles.

cool_hardware52:Doubles wings are limited in width by the center to center distance of the tanks. Most manifolds are 215 mm (8.46 inch) center to center. If you build a wing with a center panel much under 9" wide you will pinch the bladder between the tanks and the plate. There a much smaller bag of tricks one can use in designing doubles wings.

Based on recent designs, I cannot wait.

cool_hardware52:Exactly what I've been saying. 6.25" About as wide as the cylinder. Only after we introduced the LCD wings with a ~3 inch center panel did you move in that direction.

I hate to tell you that the most common cylinder used is the AL 80 and that is 8" wide.

I think I am going to start rounding down too, it looks so much better.

Patrick

----

OxyCheq

http://oxycheq.com

Similar threads

- Replies

- 2

- Views

- 386

- Replies

- 21

- Views

- 1,462

- Replies

- 6

- Views

- 421

- Replies

- 1

- Views

- 246