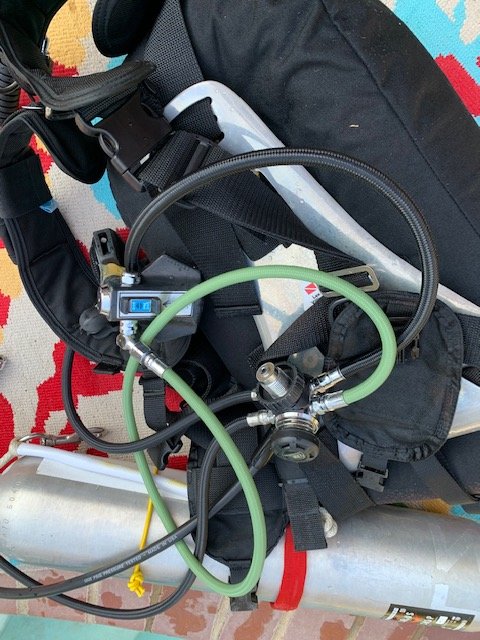

having joined the “D” club with the Scubapro D420 after years of ignoring the concept, since the tried and true in-line system balanced regs like the BA was always “good enough” and easy to service and adjust, the D just seemed weird, I had the D400 for years but never used it, finally traded off the excitement from some here over the “new” D made me look again and it’s didn’t start off well, all covered in the super long and still going D420 thread. Early adoption usually comes with problems and adjusting pains and the 420 was not only no exception but sort of a poster child for this yet with some tuning and a lot of experimental tweaking it has turned out to be a really amazing performer “in the water” and with the James79 adjuster allowing for in water adjusting the performance in great.

Rob Singler has (@rsingler) dome some videos explaining the advantages of the D series regulators and the lower position of the diaphragm for ease and utter smoothness of breathing from these types of regulators.

I wanted to get a better understanding oof this “system” so I figured to go to the beginning, the Scubapro A.I.R.1

There is very little information on these the first SP of this type, the Pilot was a similar concept but with a completely different valve design (my understanding anyway) that was often converted the the AIR1 guts.

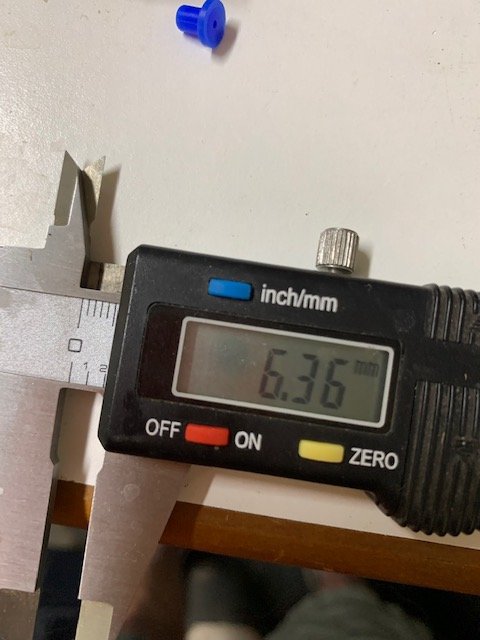

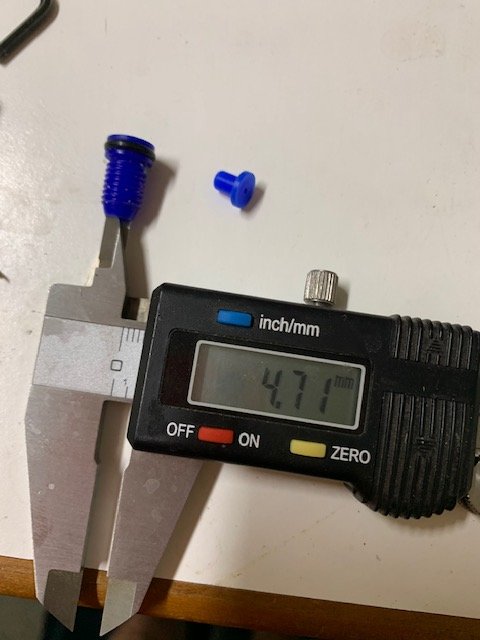

In the water the AIR1 is simply amazing, all you need to do to breath is start thinking about it, no effort, no cracking etc. you just breath! Diaphragm placement can’t be the only reason although that along with the short path of air travel have or get most of the credit, I did look at the orifice of a “conventional” regulator, here is as best as I can measure the orifice opening of the center balance

And this is the “conventional” orifice (Zeagle in this case, will go check a SP one later) the surface area may be part of the delivery improvement (?)

One of the more weird in the AIR1 (also the pilot I believe) was no exhaust valve! Other than this area of the main diaphragm (somewhere around 90° or less) the majority of the diaphragm is also the exhaust valve! (Weird concept)

The cover for this otherwise one piece case is also a guide/alignment for the main diaphragm to keep it from misbehaving during its dual use.

Adjusting lever height is easily done without removing the diaphragm clip, just pull it out of the way and adjust, this is a critical adjustment for the design, there is also a spring adjustment in the top cap for fine tuning.

It turns out the G250 cover tool works perfectly for these.

I’m not into vintage for vintage sake, this is about performance, this was as big a breakthrough as they said “back in the day” I now have 4 of these “antiques” and have them on pony bottles where the flatness fits the role perfectly.

The D420 follows the same concepts, I still don’t know why it’s dry performance is so poor compared to its ease of use in the water, they didn’t make major changes over the original design, mostly a small change the the valve body poppet centering. The old AIR1 uses the poppet from the D400 as a direct swap and the later ones that are rebuildable can keep a lot of those things going for some time yet. I like this design over the D300/350/400 because the lack of the big rubber exhaust port that makes up the majority of the case, when these fail there are no replacements so you have to scrap one to save one.

Rob Singler has (@rsingler) dome some videos explaining the advantages of the D series regulators and the lower position of the diaphragm for ease and utter smoothness of breathing from these types of regulators.

I wanted to get a better understanding oof this “system” so I figured to go to the beginning, the Scubapro A.I.R.1

There is very little information on these the first SP of this type, the Pilot was a similar concept but with a completely different valve design (my understanding anyway) that was often converted the the AIR1 guts.

In the water the AIR1 is simply amazing, all you need to do to breath is start thinking about it, no effort, no cracking etc. you just breath! Diaphragm placement can’t be the only reason although that along with the short path of air travel have or get most of the credit, I did look at the orifice of a “conventional” regulator, here is as best as I can measure the orifice opening of the center balance

And this is the “conventional” orifice (Zeagle in this case, will go check a SP one later) the surface area may be part of the delivery improvement (?)

One of the more weird in the AIR1 (also the pilot I believe) was no exhaust valve! Other than this area of the main diaphragm (somewhere around 90° or less) the majority of the diaphragm is also the exhaust valve! (Weird concept)

The cover for this otherwise one piece case is also a guide/alignment for the main diaphragm to keep it from misbehaving during its dual use.

Adjusting lever height is easily done without removing the diaphragm clip, just pull it out of the way and adjust, this is a critical adjustment for the design, there is also a spring adjustment in the top cap for fine tuning.

It turns out the G250 cover tool works perfectly for these.

I’m not into vintage for vintage sake, this is about performance, this was as big a breakthrough as they said “back in the day” I now have 4 of these “antiques” and have them on pony bottles where the flatness fits the role perfectly.

The D420 follows the same concepts, I still don’t know why it’s dry performance is so poor compared to its ease of use in the water, they didn’t make major changes over the original design, mostly a small change the the valve body poppet centering. The old AIR1 uses the poppet from the D400 as a direct swap and the later ones that are rebuildable can keep a lot of those things going for some time yet. I like this design over the D300/350/400 because the lack of the big rubber exhaust port that makes up the majority of the case, when these fail there are no replacements so you have to scrap one to save one.