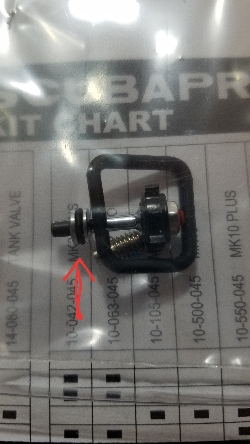

For those of you that have plenty of old seats and use the reuseable stem for the D-400 poppet (metal orifice), I just had a custom run of 1.01mm x 4.57mm EPDM 50 durometer orings made for me. It's this o-ring:

This oring was part of a problem I felt I had getting consistent sealing at low cracking effort.

Feeling the o-ring in the kit, it seemed as if it had hardened to more than the original spec.

Actually, this oring will work in any D-series poppet, including the single piece ones. If you are hoarding an old supply, the stem o-rings may have hardened.

After the setup charge and minimum run, they came to about $1 each. I had to make over a hundred of them, so happy to stick a few in an envelope for anyone who wants 'em. Just send me a PM. Even I don't have that many D's!

Of course, there's still the perennial problem of variability in the smoothness of the seat itself, but that's another issue. I've had no success making custom seats, despite multiple tries.

This oring was part of a problem I felt I had getting consistent sealing at low cracking effort.

Feeling the o-ring in the kit, it seemed as if it had hardened to more than the original spec.

Actually, this oring will work in any D-series poppet, including the single piece ones. If you are hoarding an old supply, the stem o-rings may have hardened.

After the setup charge and minimum run, they came to about $1 each. I had to make over a hundred of them, so happy to stick a few in an envelope for anyone who wants 'em. Just send me a PM. Even I don't have that many D's!

Of course, there's still the perennial problem of variability in the smoothness of the seat itself, but that's another issue. I've had no success making custom seats, despite multiple tries.