I've got to explore this for my Pilot (converted), my Air1 collection, and my D-Series collection...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

solution for D-series poppet seat DIY?

- Thread starter Kupu

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I just changed mine in the 420, it had taken on a groove and would dribble unless I gave a small puff after inhaling. I serviced the reg using all factory parts, good performance but nothing like the 104.

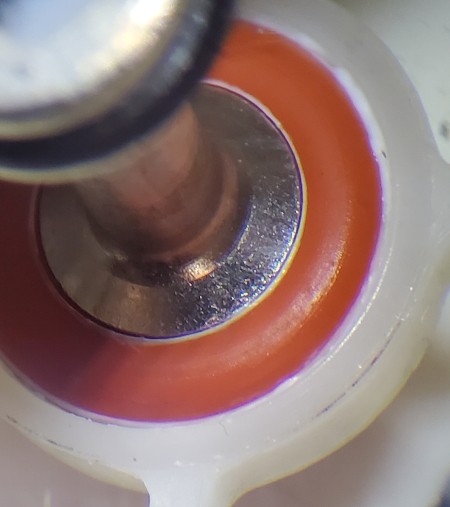

The D70 silicone 104 o-ring is almost unmarked.

Cracks at 0.6

There's a little separation of the RTV at the poppet shaft, but the attachment to the plastic cap still looks good.

Cracks at 0.6

There's a little separation of the RTV at the poppet shaft, but the attachment to the plastic cap still looks good.

Thank you to all who have been pursuing this! (This the thankful time after all) Beside my D400-RS  , relevance has maybe just jumped a notch with the arrival last week of a value-ish, minty (at least externally), late-model D400. That, and the recent updates, got me to reread the whole thread.

, relevance has maybe just jumped a notch with the arrival last week of a value-ish, minty (at least externally), late-model D400. That, and the recent updates, got me to reread the whole thread.

The much larger shaft and cap seating surfaces of the X-ring style seems attractive for durability of the RTV sealing. @rsingler, I know you started out with an X as an early trial, but, if I have the chronology right, that was before you got to the RTV as part of the shaft sealing. Do you have a sense if the "leaking" at higher IP was bypass at the shaft or was incompatibility with the knife-edge. I could certainly see that seating of the knife-edge could be greatly complicated by the recessed surface of the x-ring- it could just as easily land around/within, instead of "on" the knife edge depending on the profile interactions.

And that got me to thinking ... What about a square-profile ring?:

What about a square-profile ring?:

It increases the overall stiffness with the increased cross-sectional area and better fill of the corners, so should be more resistant to flexing the shaft/cap sealing surfaces under IP and seat-sealing cycles. Arguably, there is less space for the RTV - marginally less total bonding surface to the ring and less-total volume - for net good or ill.

Since it would have a flat surface to interact with the knife edge, there shouldn't be any negative geometric interaction.

At least in theory, they should be available in size -104 in a range of materials and hardnesses (Reference: - Rubber Square Ring Seal Sizing Chart | All O-Rings) including Silicone 70 which seems to be the current front-runner.

Where I see the greatest potential fundamental problem is that the square rings have a slightly reduced "thickness" compared to a standard o-ring:

The OD of the Square profile is 0.310" vs 0.318" for a round or x-profile. If I have this all correctly, the seat to (outer) cap sealing is not particularly critical - but it is probably critical in how it supports the ring from expanding away from the shaft. Depending on the actual ID of the cup, it could be a very tight fit (good?) or too loose - almost certainly bad. Bedding it in RTV, might provide sufficient space filling against the outside of the cap and make the OD difference a non-issue if it is too loose.

I tend to think that the lower metric o-ring would not be suitable with a square-profile.

The height is slightly reduced as well - potentially interacting with spring length and shimming?

ETA: What about a Polyurethane composition for better compression-set resistance?

I leave for y'all to ruminate over with your turkey sandwiches.

The much larger shaft and cap seating surfaces of the X-ring style seems attractive for durability of the RTV sealing. @rsingler, I know you started out with an X as an early trial, but, if I have the chronology right, that was before you got to the RTV as part of the shaft sealing. Do you have a sense if the "leaking" at higher IP was bypass at the shaft or was incompatibility with the knife-edge. I could certainly see that seating of the knife-edge could be greatly complicated by the recessed surface of the x-ring- it could just as easily land around/within, instead of "on" the knife edge depending on the profile interactions.

And that got me to thinking ...

It increases the overall stiffness with the increased cross-sectional area and better fill of the corners, so should be more resistant to flexing the shaft/cap sealing surfaces under IP and seat-sealing cycles. Arguably, there is less space for the RTV - marginally less total bonding surface to the ring and less-total volume - for net good or ill.

Since it would have a flat surface to interact with the knife edge, there shouldn't be any negative geometric interaction.

At least in theory, they should be available in size -104 in a range of materials and hardnesses (Reference: - Rubber Square Ring Seal Sizing Chart | All O-Rings) including Silicone 70 which seems to be the current front-runner.

Where I see the greatest potential fundamental problem is that the square rings have a slightly reduced "thickness" compared to a standard o-ring:

| Type | C.S. Height | C.S. Width | I.D. | O.D. | Reference Link | |

|---|---|---|---|---|---|---|

| Round | 0.103 | 0.103 | 0.112 | 0.318 |

AS568 O-Ring Size Chart | Standard USA O-Ring Sizes | |

| X-Prof | 0.103 | 0.103 | 0.112 | 0.318 |

Standard Size Charts for Quad-Ring® Seals and X-Ring Seals | |

| Square | 0.099 | 0.099 | 0.112 | 0.310 |

Rubber Square Ring Seal Sizing Chart | All O-Rings |

The OD of the Square profile is 0.310" vs 0.318" for a round or x-profile. If I have this all correctly, the seat to (outer) cap sealing is not particularly critical - but it is probably critical in how it supports the ring from expanding away from the shaft. Depending on the actual ID of the cup, it could be a very tight fit (good?) or too loose - almost certainly bad. Bedding it in RTV, might provide sufficient space filling against the outside of the cap and make the OD difference a non-issue if it is too loose.

I tend to think that the lower metric o-ring would not be suitable with a square-profile.

The height is slightly reduced as well - potentially interacting with spring length and shimming?

ETA: What about a Polyurethane composition for better compression-set resistance?

I leave for y'all to ruminate over with your turkey sandwiches.

I think you are basically describing the stock seat. It’s my belief that the slight curve of the 104 seat smooths the flow, I’ve just put a stock seat back into my D420 and while it still performs well the drop off is noticeable to me, I may put the other poppet back in to further test my theory, the 104 seat looks exactly like it did a year ago so I think the rest of the reg needed a relube because it was getting sluggish and I’m wondering if the dribble was more of a lube issue.Thank you to all who have been pursuing this! (This the thankful time after all) Beside my D400-RS, relevance has maybe just jumped a notch with the arrival last week of a value-ish, minty (at least externally), late-model D400. That, and the recent updates, got me to reread the whole thread.

The much larger shaft and cap seating surfaces of the X-ring style seems attractive for durability of the RTV sealing. @rsingler, I know you started out with an X as an early trial, but, if I have the chronology right, that was before you got to the RTV as part of the shaft sealing. Do you have a sense if the "leaking" at higher IP was bypass at the shaft or was incompatibility with the knife-edge. I could certainly see that seating of the knife-edge could be greatly complicated by the recessed surface of the x-ring- it could just as easily land around/within, instead of "on" the knife edge depending on the profile interactions.

And that got me to thinking ...What about a square-profile ring?:

It increases the overall stiffness with the increased cross-sectional area and better fill of the corners, so should be more resistant to flexing the shaft/cap sealing surfaces under IP and seat-sealing cycles. Arguably, there is less space for the RTV - marginally less total bonding surface to the ring and less-total volume - for net good or ill.

Since it would have a flat surface to interact with the knife edge, there shouldn't be any negative geometric interaction.

At least in theory, they should be available in size -104 in a range of materials and hardnesses (Reference: - Rubber Square Ring Seal Sizing Chart | All O-Rings) including Silicone 70 which seems to be the current front-runner.

Where I see the greatest potential fundamental problem is that the square rings have a slightly reduced "thickness" compared to a standard o-ring:

Type C.S. Height C.S. Width I.D. O.D. Reference Link Round 0.103 0.103 0.112 0.318 AS568 O-Ring Size Chart | Standard USA O-Ring Sizes

www.allorings.com

X-Prof 0.103 0.103 0.112 0.318 Standard Size Charts for Quad-Ring® Seals and X-Ring Seals

www.allorings.com

Square 0.099 0.099 0.112 0.310 Rubber Square Ring Seal Sizing Chart | All O-Rings

www.allorings.com

The OD of the Square profile is 0.310" vs 0.318" for a round or x-profile. If I have this all correctly, the seat to (outer) cap sealing is not particularly critical - but it is probably critical in how it supports the ring from expanding away from the shaft. Depending on the actual ID of the cup, it could be a very tight fit (good?) or too loose - almost certainly bad. Bedding it in RTV, might provide sufficient space filling against the outside of the cap and make the OD difference a non-issue if it is too loose.

I tend to think that the lower metric o-ring would not be suitable with a square-profile.

The height is slightly reduced as well - potentially interacting with spring length and shimming?

ETA: What about a Polyurethane composition for better compression-set resistance?

I leave for y'all to ruminate over with your turkey sandwiches.

Am interesting thought! The smaller OD shouldn't be a problem. That could be filled with RTV. You're right, it's the shaft binding that is key to making the seal that is the one flaw in a non-metal-backed disc. That's why I was initially excited about the X-ring. Since there's a recess in the cap for the top o-ring, it might work. However the flat top of a square profile would have to exactly mate with that. On the other hand, a square profile (and some RTV) might make the top o-ring redundant.And that got me to thinking ...What about a square-profile ring?:

The flexion of a soft silicone seal is problematic. One would hope that the displacement which caused the separation of my duro 70 silicone seal there at the bottom of the shaft would not propagate up the shaft with a square seal. A little worrisome.

Let's give it a try! We'll see if the shape affects flow and seal.

The rounded soft-seat profile may very well be improving the response.I think you are basically describing the stock seat. It’s my belief that the slight curve of the 104 seat smooths the flow, I’ve just put a stock seat back into my D420 and while it still performs well the drop off is noticeable to me, I may put the other poppet back in to further test my theory, the 104 seat looks exactly like it did a year ago so I think the rest of the reg needed a relube because it was getting sluggish and I’m wondering if the dribble was more of a lube issue.

I didn't find a good underside picture of the complete poppet assembly. Does the factory seat sit recessed in the cap?

new 400 poppet, the 420 poppet just removed from my 420 and a loose seat that shows that they are molded around a brass part that I believe allows the tiny o-ring to seal on the shaft without the ability to “wiggle” out of place.The rounded soft-seat profile may very well be improving the response.

I didn't find a good underside picture of the complete poppet assembly. Does the factory seat sit recessed in the cap?

new 400 poppet, the 420 poppet just removed from my 420 and a loose seat that shows that they are molded around a brass part that I believe allows the tiny o-ring to seal on the shaft without the ability to “wiggle” out of place.

I wonder how much of the difference is that the recessed factory seat has the cap sitting lower over the orifice and occluding flow vs. the shape of the Kupu o-ring seat.

Shame there is no real way to shim the factory seat to sit flush or just proud of the cap. Maybe shave the rim of the cap down if you have a spare/trash one suitable for testing only?

I wonder how much of the difference is that the recessed factory seat has the cap sitting lower over the orifice and occluding flow vs. the shape of the Kupu o-ring seat.

Shame there is no real way to shim the factory seat to sit flush or just proud of the cap. Maybe shave the rim of the cap down if you have a spare/trash one suitable for testing only?

There may be enough lever adjustment to do that but no longer have any older D’s around to try it but on the 420 you can see the same lip.

Similar threads

- Replies

- 14

- Views

- 1,532

- Replies

- 2

- Views

- 396

- Replies

- 14

- Views

- 1,331