+ the vodka of your choice, heh, heh . . .If only there were a better way

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atomic regs/cold water?

- Thread starter brsnow

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

davecampbell

Contributor

thanks for this sir. I appreciate you taking the time.I think the tool still leaves voids.

Sure. I'll make a video and post that.

It's pretty straightforward.

Get a syringe and blunt needle. I can send you some plastic blunt needles that are perfect if you need one.

Starting at the bottom coil, fill the spring from the inside out, working your way up to the top. Add a thin layer to the outside of the spring.

Put the environmental seal on the reg after putting a thin line of lube circumferentially in each corner of the seal. Don't try to fill it.

Fill the ring deep in the body where the spring end will rest. This will displace lube UP toward the holes as you assemble.

Run a line of lube in between each ambient hole of the interior of the reg body up to the rim.

All this will take approx 8cc of lube.

View attachment 722263

Slowly insert the piston and bullet until the spring bottoms. If you haven't been liberal enough, manually press on the piston head until goop and (hopefully few) bubbles almost start to squeeze around the head. After you release pressure, fill the gap between head and reg body, and wipe out to a clean line (you don't want much spilling into the IP chamber, tho some will).

Add the turret and slowly screw on.

You'll hear the seal click and pop as air in the seal escapes. Massage the seal before it's completely screwed on to distribute lube that has come out the ambient holes.

Finish screwing on the turret. The seal should be bulging slightly. Using a pinch technique like for removing an oring, squeeze the seal to express excess lube and any stray bubbles until it is just slightly concave.

Assuming you previously assembled, checked IP stability and disassembled the first stage before filling, repressurize it. The seal will once again bulge. Express excess lube again (wiping your fingertip against the rim of some small container where you keep your excess for the next six years of orings), until the seal is just flat when pressurized. This technique will waste approx 1.5cc of lube.

When you depressurize, it will suck in firmly concave. You're done.

But the extent to which the Atomic seal goes from full and flat (pressurized) to really concave (unpressurized) shows why I keep a spare 2cc syringe of lube around to top up the seal every 3-6 months of diving. Unless you are really careful about not handling the seal when pressurized, you'll inadvertently squeeze out some lube on a dive trip, and a small bubble of air will replace it under the seal when off the tank. That's not really an issue, because it's all outside the spring mechanism. But it does fractionally reduce the responsiveness of the reg to ambient pressure.

I think the tool still leaves voids.

Sure. I'll make a video and post that.

It's pretty straightforward.

Get a syringe and blunt needle. I can send you some plastic blunt needles that are perfect if you need one.

Starting at the bottom coil, fill the spring from the inside out, working your way up to the top. Add a thin layer to the outside of the spring.

Put the environmental seal on the reg after putting a thin line of lube circumferentially in each corner of the seal. Don't try to fill it.

Fill the ring deep in the body where the spring end will rest. This will displace lube UP toward the holes as you assemble.

Run a line of lube in between each ambient hole of the interior of the reg body up to the rim.

All this will take approx 8cc of lube.

View attachment 722263

Slowly insert the piston and bullet until the spring bottoms. If you haven't been liberal enough, manually press on the piston head until goop and (hopefully few) bubbles almost start to squeeze around the head. After you release pressure, fill the gap between head and reg body,

View attachment 722587

and wipe out to a clean line (you don't want much spilling into the IP chamber, tho some will).

Add the turret and slowly screw on.

You'll hear the seal click and pop as air in the seal escapes. Massage the seal before the cap is completely screwed on to distribute lube that has come out the ambient holes.

Finish screwing on the turret. The seal should be bulging slightly. Using a pinch technique like for removing an oring, squeeze the seal to express excess lube and any stray bubbles until it is just slightly concave.

Assuming you previously assembled, checked IP stability and disassembled the first stage before filling, repressurize it. The seal will once again bulge. Express excess lube again (wiping your fingertip against the rim of some small container where you keep your excess for the next six years of orings), until the seal is just flat when pressurized. This technique will waste approx 1.5cc of lube.

When you depressurize, it will suck in firmly concave. You're done.

But the extent to which the Atomic seal goes from full and flat (pressurized) to really concave (unpressurized) shows why I keep a spare 2cc syringe of lube around to top up the seal every 3-6 months of diving. Unless you are really careful about not handling the seal when pressurized, you'll inadvertently squeeze out some lube on a dive trip, and a small bubble of air will replace it under the seal when off the tank. That's not really an issue, because it's all outside the spring mechanism. But it does fractionally reduce the responsiveness of the reg to ambient pressure.

Have you made a video of this process yet?

Your method appears to be more complicated than the standard method but a video will make it much simpler

No video yet. Plate too full with Reg Tech Seminars.

More complicated? Slightly.

More difficult? Not at all.

Better at avoiding voids/bubbles? Absolutely.

Even allowing for the new gaps in the lube that must form when the piston is removed and the spring expands, water doesn't belong there.

Filling blindly with the tool allows this to happen.

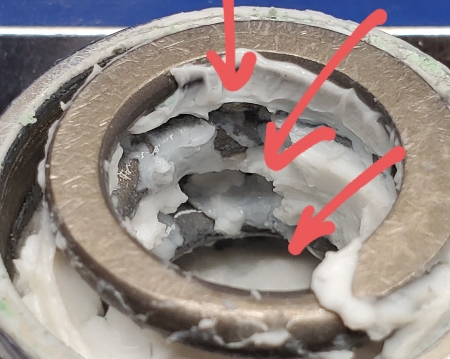

This is how mine look before insertion, after using a syringe.

More complicated? Slightly.

More difficult? Not at all.

Better at avoiding voids/bubbles? Absolutely.

Even allowing for the new gaps in the lube that must form when the piston is removed and the spring expands, water doesn't belong there.

Filling blindly with the tool allows this to happen.

This is how mine look before insertion, after using a syringe.

- Messages

- 17,699

- Reaction score

- 9,970

- Location

- Somewhere between here and there

- # of dives

- 2500 - 4999

It's called a sealed diaphragmIf only there were a better way

Or a sherwoodIt's called a sealed diaphragm

Mostly I learned that Atomic is a horrible tease, my guess was they were going to hijack the F8 design and make it in titanium (already have Atomic parts inside the F8 second)Maybe there's something coming...

At only $2,700!

Atomic just released a teaser for a new reg that @BoltSnap sent me.

What can we deduce from these?

View attachment 785133View attachment 785134

Told you it was a teaser!

at $2700 as close as I’ll get to one is a display case

Looks like the opening for an old Twilight Zone episode . . .Maybe there's something coming...

At only $2,700!

Atomic just released a teaser for a new reg that @BoltSnap sent me.

What can we deduce from these?

View attachment 785133View attachment 785134

Told you it was a teaser!

- Messages

- 17,699

- Reaction score

- 9,970

- Location

- Somewhere between here and there

- # of dives

- 2500 - 4999

That's a whole bunch of money. If the whole second stage was titanium I'd be excited. I like titanium. Why? Just coz.

Similar threads

- Replies

- 21

- Views

- 2,684