You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Al 80 vs HP100 useable amount of air

- Thread starter Scuba-guy

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

This is my go to intro on tank sizes and AL vs steel (for imperial measurements).

daniellesdives.wordpress.com

daniellesdives.wordpress.com

Rich asks…Why are you diving with that Tank?

First off, I am going to do a quick intro here. Hubby Rich as many of my followers know is OCD about the equipment. I love him and never have to worry about things going wrong. With that said, wher…

I do not feel superior. It is the SI unit system which is inherently superior, simply because it is a coherent system.The OP is from the US and posted in imperial units. I am from the US and posted in imperial units. I'm glad you feel superior. I often post in both imperial and metric units to enhance international communication

Average Gas Consumption

Apparently, I have both above and below average consumption. At the end of a week in Cozumel this summer, with no wet suit, I was down to around 10 L/min. This weekend in Catalina, 8/7mm suit, hood, 3mm gloves, surge, current, etc., I was a bit over 20 L/min. In customary units, .35 to .75...scubaboard.com

Question - Definitions for SAC and RMV?

This topic comes up over and over. Let's see what you think. Please vote once for SAC and once for RMV or vote for #5 and elaborate in your post or #6 if you don't know what this is all about.scubaboard.com

I nearly always dive AL80s in the US and when diving land-based or on a liveaboard outside of the US as that is all the gas I need. In my experience, these cylinders are usually filled to an average pressure of greater than 3000psi/207 bar. Here is a table of all my fills for 2021 and 2022. Average fill pressures were all above 3000 psi/207 bar. The lowest fill pressures are not bad. With the exception of Florida, HP steel tanks are not available on these trips. Perhaps if I used HP cylinders, the fill pressures would not look as good. Sorry you get poor fills.

View attachment 779342

But this was not the point I wanted to raise. I did the calculations in SI units just because 95% of world population uses it, and I am more used to it.

But I could as well have done the calculation in Imperial units, and the conclusion had been exactly the same.

My point was another: it is misleading to label a tank by the total rated volume at nominal pressure. Using different units is irrelevant, it is exactly thr same (bad) concept to label a tank as "80 Cuft" or as "2200 liters".

My point is that tanks should be identified by their real capacity (either 0.39 cuft or 11 liters), and then the user should evaluate the total available air volume by multipliying for the pressure measured by the SPG.

Which is what we do here in Europe, but apparently is not what is done in US, according to the examples posted before my post.

I really hope to be wrong on this assumption...

- Messages

- 21,449

- Reaction score

- 21,657

- Location

- Philadelphia and Boynton Beach

- # of dives

- 2500 - 4999

Hi @Angelo Farina

No, we use crappy imperial units, always have, likely, always will. You work with what you have. It's quite easy for me after more than 2250 dives over the last 25 years.

No, we use crappy imperial units, always have, likely, always will. You work with what you have. It's quite easy for me after more than 2250 dives over the last 25 years.

So in the example above 100/3442 is the “quantity” of gas at 1 psi in cubic feet?Using the figures from you and Angelo for a partially filled cylinder.

Imperial. 100/3442*3000 = 87 cf

Metric. 13*200 = 2600L

Although the Imperial calculation is not difficult, the metric one looks less likely to produce errors.

My 10L UK cylinders have stamped on them: 232BAR, 10.0L. I have never seen a US cylinder. Do the HP100 cylinders have 100cf stamped on them?

Of course when one is grown up with a system, that becomes easier to work with.Hi @Angelo Farina

No, we use crappy imperial units, always have, likely, always will. You work with what you have. It's quite easy for me after more than 2250 dives over the last 25 years.

But this was not my point.

The problem is labelling tanks improperly.

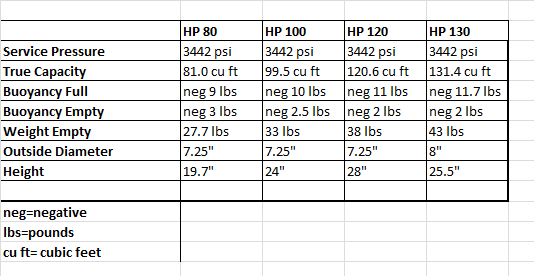

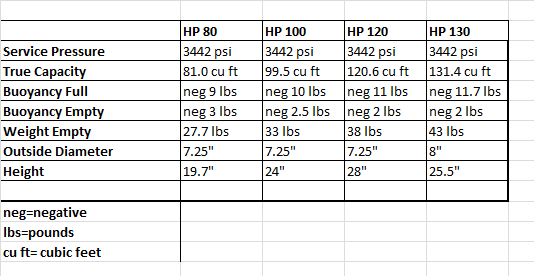

Back to the OP. The question is how much increase of available gas you get using an HP100 over an AL80.

Apparently using these labels one can think to get an improvement of 20/80 = 25%.

Instead using the real capacity of these tanks (0.4366 and 0.3923 cuft respectively) one gets just an 11.23% increase.

The problem is that these real capacity numbers are difficult to find, and I am not 100% sure of having got the correct ones.

So, for the OP.

The pressure you see on the SPG translates into an amount of available gas which is just 11% larger than when using an AL80.

Not 25%...

@BlueTrin, the two systems have different conventions about how to name the tank. In the SI system, we name it after the internal volume of the tank: how much water can fit in there. And we calculate the amount of pressurized gas by multiplying that volume by the pressure: so a 12L tank at 240 bar holds about 2880 liters of gas.

In the US system, we name the tank based on how much gas it could hold, if that gas were to expand out to 1 atmostphere of pressure. So the internal volume of a 100CF tank is only about 0.42 cubic feet, and at service pressure (typically 3442 psi, sometimes 3500 psi), the tank holds 100 cubic feet of gas at atmospheric pressure.

Incidentally, 3442 psi is about 237 bar, and HP100's hold about 2837 liters of gas at service pressure. So an HP100 is very similar to a 12L rated for 240 bar on paper (and in practice, they might even be identical tanks, I'm not sure. A tank expert would know for sure, and there are some in this thread).

Edit to add a few conversions, maybe they'll come in handy:

1 cf = 28.3168 L

1 L = 0.0353147 cf

1 bar = 14.6959 psi

1 psi = 0.068046 bar

1 inch = 2.54 cm

1 cm = 0.393701 inch

1 kg = 2.20462 pound

1 pound = 0.453592

In the US system, we name the tank based on how much gas it could hold, if that gas were to expand out to 1 atmostphere of pressure. So the internal volume of a 100CF tank is only about 0.42 cubic feet, and at service pressure (typically 3442 psi, sometimes 3500 psi), the tank holds 100 cubic feet of gas at atmospheric pressure.

Incidentally, 3442 psi is about 237 bar, and HP100's hold about 2837 liters of gas at service pressure. So an HP100 is very similar to a 12L rated for 240 bar on paper (and in practice, they might even be identical tanks, I'm not sure. A tank expert would know for sure, and there are some in this thread).

Edit to add a few conversions, maybe they'll come in handy:

1 cf = 28.3168 L

1 L = 0.0353147 cf

1 bar = 14.6959 psi

1 psi = 0.068046 bar

1 inch = 2.54 cm

1 cm = 0.393701 inch

1 kg = 2.20462 pound

1 pound = 0.453592

So the real point is: what is the true capacity when filling by water an AL80 and an HP100 (either in cuft or in liters, I don't care)?

Is this value stamped on the tank, as it happens here?

Is this value stamped on the tank, as it happens here?

Aren't you forgetting that the HP100 has more gas in it because the pressure is higher? Should not the comparison be between 2832 liters (the full HP100) and 2192 liters (the full AL80)? Thus 29%?Of course when one is grown up with a system, that becomes easier to work with.

But this was not my point.

The problem is labelling tanks improperly.

Back to the OP. The question is how much increase of available gas you get using an HP100 over an AL80.

Apparently using these labels one can think to get an improvement of 20/80 = 25%.

Instead using the real capacity of these tanks (0.4366 and 0.3923 cuft respectively) one gets just an 11.23% increase.

The problem is that these real capacity numbers are difficult to find, and I am not 100% sure of having got the correct ones.

So, for the OP.

The pressure you see on the SPG translates into an amount of available gas which is just 11% larger than when using an AL80.

Not 25%...

Again the same wrong concept.Aren't you forgetting that the HP100 has more gas in it because the pressure is higher? Should not the comparison be between 2832 liters (the full HP100) and 2192 liters (the full AL80)? Thus 29%?

That is the theoretical maximum gas content.

But the real content is given by the tank volume multiplied by the pressure you read on the SPG after splashing down. This is often very different from the max rated pressure...

And the OP was specifically asking about how pressure shown by the SPG behaves on the two tanks.

This depends just on their real capacity, not on the max rated pressure.

Similar threads

- Replies

- 5

- Views

- 572

- Replies

- 55

- Views

- 4,605

- Replies

- 13

- Views

- 1,885

- Replies

- 15

- Views

- 2,147