Something like this but capable of running the pressure needed to fill scuba tanks?

My club has a tank house with ~400 tanks. A system where the tanks could be filled on the storage racks would be ideal.

I know one option would be just having a long hose, maybe on a retractable reel, with a manifold attached to run 4 fill whips is one option.

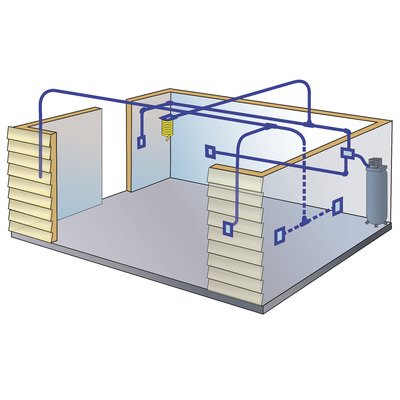

Just wondering if something has ever been done where a room is piped/plumbed with QD outlets where a whip manifold could be hooked up to different areas rather than dragging a longer hose around.

I assume it could be done using something like these since they're rated to 3,000 psi? It looks like they're made for metal lines though. Or maybe something like this?

I assume the plumbing would have to be heavy duty hose which could get expensive unless metal plumbing could be used? If so what kind would be used?

My club has a tank house with ~400 tanks. A system where the tanks could be filled on the storage racks would be ideal.

I know one option would be just having a long hose, maybe on a retractable reel, with a manifold attached to run 4 fill whips is one option.

Just wondering if something has ever been done where a room is piped/plumbed with QD outlets where a whip manifold could be hooked up to different areas rather than dragging a longer hose around.

I assume it could be done using something like these since they're rated to 3,000 psi? It looks like they're made for metal lines though. Or maybe something like this?

I assume the plumbing would have to be heavy duty hose which could get expensive unless metal plumbing could be used? If so what kind would be used?