Scuba Lawyer

Contributor

I finished my rebuild of my 1956 Bill Arpin designed DivAir Model F (distributed by Healthways). I am informed this was the last DivAir model made. It has the aluminum can and fibreglass body. My research showed it originally came with blue hoses and a Hope-Page mouthpiece so that is how I rebuilt it.

Very simple upstream one-stage design that is different enough from the Voit Sportsman or a USD StreamAir to avoid any patent infringement problems. No venturi assist, but the air is directed right down the intake horn without much spillage into the rest of the can. As with all upstream regs I tuned it on a 300-500 psi tank. It has a, for want of a better description, a macro main lever height adjustment screw and a micro adjustment screw (both locking) that permits very fine tuning. Cracking pressure at 300 psi is .5" H20 and cracking pressure at 2250 psi is just a hair over 1.5" H20. It breathes amazingly!

The built in reserve mechanism is awesome and simple. Kicks in at about 500 psi. The reserve mechanism can also be easily rotated (via an extra screw hole) so the reg will fit on twin tanks. I can tell a lot of thought went into the design.

Special thanks to Nuytco Research, Ltd.'s submersible vehicle pilot Jeff Heaton for casting a new diaphragm and hoses for me!!!

Gonna take this puppy out for a test dive next week! Can’t wait!

Advertisement image courtesy of Vintage Double Hose.

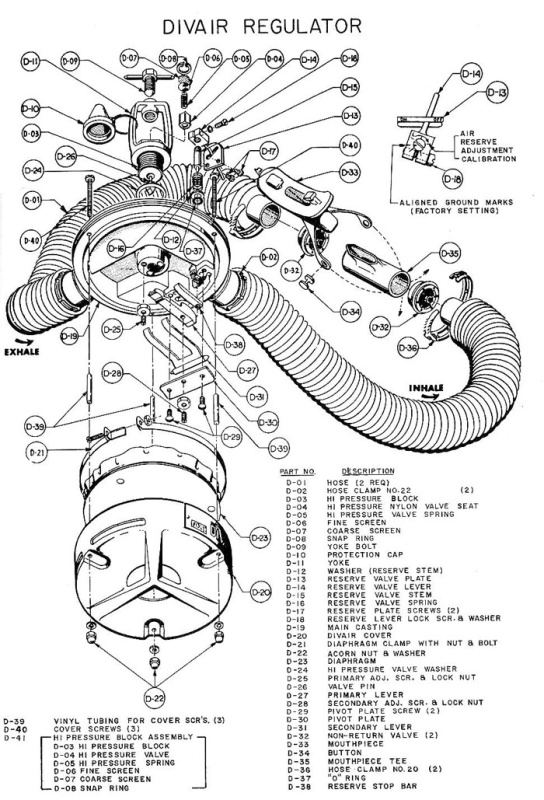

Diagram from Roberts, Basic Scuba (1960)

cc: @Sam Miller III

Very simple upstream one-stage design that is different enough from the Voit Sportsman or a USD StreamAir to avoid any patent infringement problems. No venturi assist, but the air is directed right down the intake horn without much spillage into the rest of the can. As with all upstream regs I tuned it on a 300-500 psi tank. It has a, for want of a better description, a macro main lever height adjustment screw and a micro adjustment screw (both locking) that permits very fine tuning. Cracking pressure at 300 psi is .5" H20 and cracking pressure at 2250 psi is just a hair over 1.5" H20. It breathes amazingly!

The built in reserve mechanism is awesome and simple. Kicks in at about 500 psi. The reserve mechanism can also be easily rotated (via an extra screw hole) so the reg will fit on twin tanks. I can tell a lot of thought went into the design.

Special thanks to Nuytco Research, Ltd.'s submersible vehicle pilot Jeff Heaton for casting a new diaphragm and hoses for me!!!

Gonna take this puppy out for a test dive next week! Can’t wait!

Advertisement image courtesy of Vintage Double Hose.

Diagram from Roberts, Basic Scuba (1960)

cc: @Sam Miller III