What the hell did I just watch?I dived for a while with a boat belonging to a Scubapro shop owned by the captain of the boat

that also serviced the Scubapro regs and plenty of other regs too, all to the manufacturers spec

and in conversation the no 1 of the boat, dive master probably the best diver dive masteer, people herder

I've ever seen, told me that he was doing less divemastering and having shorter dives because the captain

of the boat the guy that also owns the shop and does the regs tunes these regs to manufacturer specs in such

a way that all he comes across on the boat he has to spend his time detuning with the captain owner reg tuner

next to him

as every single one of them freeflow

View attachment 819178

Now the way this boat is run, people spend so much time futzing around, bobbing in water, and on the boat

I think my tuned detuned serviced myself regs would freeflow which they normally don't do out of sympathy

So again the guy detuning the regs to practical operating condition so they work properly without freeflow

does so with the original service guy standing next to him, but he continues to pump out regs that freeflow

Every reg set he does for years, and lots of people take their regs to him, he's the reg guy, the freeflow king

Hey, people don't know as knowone tells them, and some don't know their gear well enough to be diving it

Ok I'm not talking about people diving in Norway or under the ice like these fairdinkum diver dudes

but know your gear get good at diving you'll like it!

It's ok to be a horizontal diver but try diving on your back for a while or upside down, you won't like it

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Anyone ever had an incident because they serviced their own gear?

- Thread starter Tom_Ivan

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I will admit my **** ups since picking up servicing on my own, none of them ended in any incident though (looking forward to you guys telling me how it could have nonetheless).

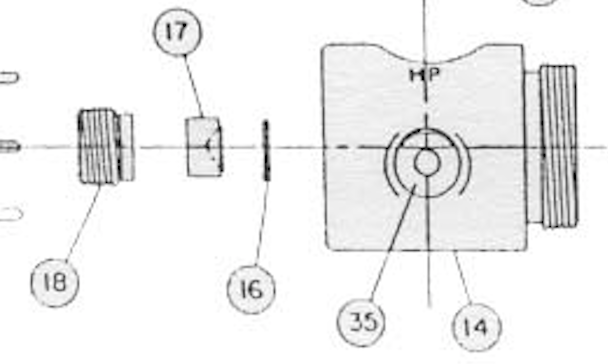

#1: Piston reg, schematic does not facilitate exact reality. #18 is the HP-Seat Housing and in my instance a screw with a head.

Instead of using O-Ring #16 "on the right side", so the bottom of the housing-screw, I put it towards the "left side", pushed it over the thread all the way to the head of the screw.

With two MK25 evos, nothing happened. With a MK5 clone, the O-Ring sat absolutely horribly (which bothered me, but not enough to recognise my mistake) and overextruded due to HP and obviously leaked. With the MK25's, I discovered that mistake around 50 dives into it, 1 year later. With the MK5, the **** up made itself clear while testing. To my excuse: The screw looked like it wanted the O-Ring where I put it, a bit of clean space inbetween the head & the thread.

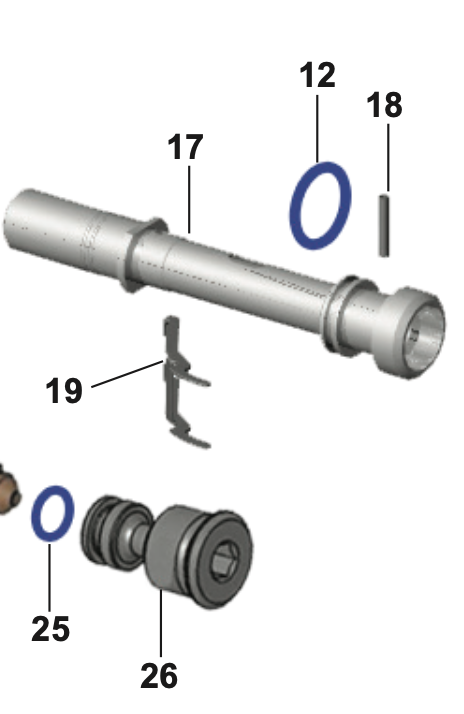

#2: I was watching TV while disassembling a second stage. Since the TV was absolutely thrilling (some wrecks I assume), I did not get rid of the pin (#18) before unscrewing #26. The screw is made of plastic and while using some force, it broke. Obviously, assembly is impossible then, no diving, no accident.

#3: I pick up ebay-regs, max 40euro, to learn servicing. A few of them are impossible (to me) to disassemble and then I break stuff.

My methods for reluctant stages in that order:

Water & vinegar

Lots of WD40 in all holes, let it sit a while.

Heat - usually "only" boiling water

Then I resolve to destructive measures, like drills, screw extractors and so on.

Two more non-destructive methods I was told since my last ebay-reg:

WD40 and pressurizing the reg (untested by me so far)

Some time in the freezer - rsingler wrote that a couple of times.

Lessons learned:

Be precise.

Focus on one task at a time.

Go with the service manual for the step-by-step (dis-)assembly.

#1: Piston reg, schematic does not facilitate exact reality. #18 is the HP-Seat Housing and in my instance a screw with a head.

Instead of using O-Ring #16 "on the right side", so the bottom of the housing-screw, I put it towards the "left side", pushed it over the thread all the way to the head of the screw.

With two MK25 evos, nothing happened. With a MK5 clone, the O-Ring sat absolutely horribly (which bothered me, but not enough to recognise my mistake) and overextruded due to HP and obviously leaked. With the MK25's, I discovered that mistake around 50 dives into it, 1 year later. With the MK5, the **** up made itself clear while testing. To my excuse: The screw looked like it wanted the O-Ring where I put it, a bit of clean space inbetween the head & the thread.

#2: I was watching TV while disassembling a second stage. Since the TV was absolutely thrilling (some wrecks I assume), I did not get rid of the pin (#18) before unscrewing #26. The screw is made of plastic and while using some force, it broke. Obviously, assembly is impossible then, no diving, no accident.

#3: I pick up ebay-regs, max 40euro, to learn servicing. A few of them are impossible (to me) to disassemble and then I break stuff.

My methods for reluctant stages in that order:

Water & vinegar

Lots of WD40 in all holes, let it sit a while.

Heat - usually "only" boiling water

Then I resolve to destructive measures, like drills, screw extractors and so on.

Two more non-destructive methods I was told since my last ebay-reg:

WD40 and pressurizing the reg (untested by me so far)

Some time in the freezer - rsingler wrote that a couple of times.

Lessons learned:

Be precise.

Focus on one task at a time.

Go with the service manual for the step-by-step (dis-)assembly.

On my very first at home by myself 2nd stage rebuild after taking @cerich awesome class I tried to tune with pressure on the seat. It seemed fine but when diving it would free flow just a little. Not enough to cause an "accident" but was pretty annoying. I swapped it out and all was good.

I think if you work on your own cars or have then it's pretty easy. If you have a mechanic's touch (ie you've broken enough **** to know how not to!)

Could I have gotten by without the class, maybe. But it was really nice to see someone else do it and have someone point out where the tricky spots were.

@rsingler teaches an online class on here as well.

Good luck!

I think if you work on your own cars or have then it's pretty easy. If you have a mechanic's touch (ie you've broken enough **** to know how not to!)

Could I have gotten by without the class, maybe. But it was really nice to see someone else do it and have someone point out where the tricky spots were.

@rsingler teaches an online class on here as well.

Good luck!

- Messages

- 8,629

- Reaction score

- 7,333

- # of dives

- 2500 - 4999

Have you heard the one where someone tries to undo something and it just won't come

then they hand it off to some of the other eager volunteers to try and they get it first go

well thats just like the freezer myth where with another take it was going to give anyway

freezer or no magical freezer

my reg guy up thread, Mr freeflow well he's a freezer guy too and mostly it doesn't work

What does work is whacking your first stage with a plastic hammer to crack the verdigris

then you can crack the thread

Freezers and ovens belong to putting ring gears on diff centres and other putting small stuff on big stuff

where you can cool or heat stuff individually, separately by themselves, not all together in a clump things

then they hand it off to some of the other eager volunteers to try and they get it first go

well thats just like the freezer myth where with another take it was going to give anyway

freezer or no magical freezer

my reg guy up thread, Mr freeflow well he's a freezer guy too and mostly it doesn't work

What does work is whacking your first stage with a plastic hammer to crack the verdigris

then you can crack the thread

Some time in the freezer - rsingler wrote that a couple of times.

Freezers and ovens belong to putting ring gears on diff centres and other putting small stuff on big stuff

where you can cool or heat stuff individually, separately by themselves, not all together in a clump things

admikar

Contributor

#3: I pick up ebay-regs, max 40euro, to learn servicing. A few of them are impossible (to me) to disassemble and then I break stuff.

My methods for reluctant stages in that order:

Water & vinegar

Lots of WD40 in all holes, let it sit a while.

Heat - usually "only" boiling water

Then I resolve to destructive measures, like drills, screw extractors and so on.

Attachments

Yes, I caused a serious accident while servicing equipment, and I risked my life.

It was a CC pure-oxygen rebreather, a Cressi ARO mod. 57B.

This was, at the time, the basic scuba system employed for training new divers here in Italy.

At the time I was an assistant instructor, and my training did include servicing these rebreathers (dismounting, washing, replacing the soda lyme, detaching the tank, filling it and reassembling everything).

The incident occurred during reassembling.

I had finished the teflon flat washers ensuring seal between the oxygen tank and the manual "bypass" valve, so I did employ a similarly-sized hard rubber washer, which evidently was not rated for pure oxygen at 200 bar.

When I opened the valve on the tank, the rubber catched fire, creating an hole in the body of the bypass valve, from which a flame beam, half a meter long, erupted.

Luckily this flame was not aimed towards my face.

I was cold enough to close the valve immediately, interrupting the oxygen supply.

It was truly dangerous and scaring.

That was one of 5 times i risked my life during my juvenile years.

It was a CC pure-oxygen rebreather, a Cressi ARO mod. 57B.

This was, at the time, the basic scuba system employed for training new divers here in Italy.

At the time I was an assistant instructor, and my training did include servicing these rebreathers (dismounting, washing, replacing the soda lyme, detaching the tank, filling it and reassembling everything).

The incident occurred during reassembling.

I had finished the teflon flat washers ensuring seal between the oxygen tank and the manual "bypass" valve, so I did employ a similarly-sized hard rubber washer, which evidently was not rated for pure oxygen at 200 bar.

When I opened the valve on the tank, the rubber catched fire, creating an hole in the body of the bypass valve, from which a flame beam, half a meter long, erupted.

Luckily this flame was not aimed towards my face.

I was cold enough to close the valve immediately, interrupting the oxygen supply.

It was truly dangerous and scaring.

That was one of 5 times i risked my life during my juvenile years.

you can actually count the number of times you risked your life as a juvenile?Yes, I caused a serious accident while servicing equipment, and I risked my life.

It was a CC pure-oxygen rebreather, a Cressi ARO mod. 57B.

This was, at the time, the basic scuba system employed for training new divers here in Italy.

At the time I was an assistant instructor, and my training did include servicing these rebreathers (dismounting, washing, replacing the soda lyme, detaching the tank, filling it and reassembling everything).

The incident occurred during reassembling.

I had finished the teflon flat washers ensuring seal between the oxygen tank and the manual "bypass" valve, so I did employ a similarly-sized hard rubber washer, which evidently was not rated for pure oxygen at 200 bar.

When I opened the valve on the tank, the rubber catched fire, creating an hole in the body of the bypass valve, from which a flame beam, half a meter long, erupted.

Luckily this flame was not aimed towards my face.

I was cold enough to close the valve immediately, interrupting the oxygen supply.

It was truly dangerous and scaring.

That was one of 5 times i risked my life during my juvenile years.

I think they just want to keep their dealers happy. They are often desperate to keep customers coming through their doors.The reg manufacturers want to keep people safe, but more importantly, the reg manufacturer's legal counsel wants to keep their client safe.

admikar

Contributor

I think there is some merit to "professional" service network. Some people shouldn't be allowed to dive, not to mention service diving equipment.I think they just want to keep their dealers happy. They are often desperate to keep customers coming through their doors.

L13

Contributor

Which is why we should keep going through the doors of the good ones, to keep them from being tempted to desperate measures.I think they just want to keep their dealers happy. They are often desperate to keep customers coming through their doors.

Similar threads

- Replies

- 2

- Views

- 657

- Replies

- 7

- Views

- 1,256

- Replies

- 59

- Views

- 5,886

- Replies

- 10

- Views

- 1,778