You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trouble breaking down my doubles

- Thread starter Graveyarddiver

- Start date

-

- Tags

- doubles setup maintenance

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Yay PB Blaster....it even sounds cool.

And it WORKS!

How to eliminate galling

Here are 7 common solutions:

Here are 7 common solutions:

- Use proper lubricants

- Slow down tightening speed

- Choose coarse threads where possible

- Avoid cut bolt threads

- Mix nut and bolt grades while maintaining mechanical properties

- Beware of prevailing torque lock nuts

- Keep threads clean; fo

7 Ways to Prevent Galling

1) Use Proper Lubricants

Pre-applied or applied on site, dry film lubricants or lubricants rich in molybdenum disulfide (moly), graphite, mica, talc and even extreme pressure waxes are effective at reducing friction. Brand names include Perma-Slik® RAC, Xylan, and DELTA® SEAL. Fluoropolymer coatings are also effective. They include PTFE, commonly referred to as Teflon, PVDF, PFA and FEP. Other remedies include Loctite and Aero-Chem® lines of anti-seize products.2) Slow Down Tightening Speed

The slower the power tool speed, the less heat is generated and the less likely galling will occur – during installation and removal. So, control speed when using powered equipment, or use hand tools where galling may occur.3) Choose Coarse Threads Where Possible

Fine threads can have more surface area and their thread clearance may be reduced. Higher thread friction can result. Use coarse threads where possible.

4) Avoid Cut Threads

Ordinary bolt threads are rolled between dies, which produce relatively smooth surfaces. Lathe-cut bolts typically have rougher threads which create more heat when coupled with nuts that usually have tapped threads.

Thread rolling. Photo Courtesy of Horst Engineering/Thread Rolling Inc.

5) Mix Nut and Bolt Grades While Maintaining Mechanical Properties

Metal grades have different hardnesses and when mixed, can stop galling. Example: use a type 304 stainless steel nut with a type 316 bolt. Generally, the softer the metal, the more apt it is to gall. Thread galling is excessive mechanical contact between mating surfaces.6) Beware of Prevailing Torque Lock Nuts

7) Keep Threads Clean and Nick-Free; Follow Torque Specs

Lock nuts like these are designed to add resistance when installed and generate lots of heat. So avoid them, or install them very slowly. Nylon insert lock nuts paired with stainless steel is a common troublesome issue.

Dirt and nicks on threads create friction and, in turn, heat. Similarly, over-torquing can stretch fasteners beyond their ability to continue creating tension (they lose their elasticity) which can lead to thread binding.

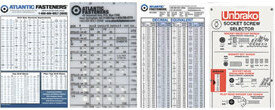

Attachments

Impact as mentioned is better than just yanking on a breaker bar. You could also try hitting the breaker bar with a mallet instead.

Nice , Thanks !

#5 Works GREAT for me.

WarrenZ

The Ultimate Bad Example

If you didnt snap the all thread then you didnt use a large enough breaker bar.

Spend a little extra and get marine grade stainless not Home Depot stainless hardware when re-assembling.

Spend a little extra and get marine grade stainless not Home Depot stainless hardware when re-assembling.

W W Meixner

Banned

I’m wondering if anyone else has faced this issue, and what there solution was. Using my angle grinder in a tight space on my bands hardware was less than desirable.

In my yearly tank maintenance I ran into a slight issue. Having removed all the valves from singles and stage bottles, it was time to break down my doubles. Both sets of my AL 80s, no issues, bands and manifold removed in about 10 minutes. Moving onto my Steel 133s, and this is where the struggle started. Removing the hardware from the first band, was a struggle, so I broke out the breaker bar, and finally got the nut/bolt loose. A few turns into the second band, and the same issue, again the breaker bar comes out, and after a few profanity laced attempts the bolt is warped, and the nut is no looser. After a few more futile attempts with a buddy, I broke out the angle grinder and VERY CARFULLY, ground the bolt so it could be removed. Not once did the grinder come close to touching my tanks or bands, 10 minutes of stressful grinding is nit something I want to repeat.

Has anyone else faced this and what were your solution? I did not use loctite on any hardware, and I’ve done this regularly with other tanks.

GYD...

Had this problem on an annual basis...HP 100 cu ft steel doubles...doesn't take much to gall the threads on the Chinese manufactured 5/16 threaded rod...

Once this happens...the nut locks on the thread and will not move...a large socket/ratchet on the bottom...and a socket and ''L'' bar on the top and twist off the threaded rod...

I always maintained at least six complete bolt/nut/washer assemblies in my tool box...

It always seemed as long as I had lots of spare bolt assemblies...I had less problem getting the existing bolts apart...get caught without a spare set...the nuts locked up every time...

I found that during fabrication of the rod assemblies...running the threaded rods over a rotary wire brush helped clean off the die flash and prolonged their life...make sure you're wearing safety glasses...

I also found that standard nuts and standard lock washers worked better than Nylock nuts...

Hope this helps...

Warren

Similar threads

- Replies

- 8

- Views

- 718

- Replies

- 1

- Views

- 362

- Replies

- 9

- Views

- 1,533