So, quite a while ago, I bought a pair of fenders. These are 10x19x36 "Jeep Style" fenders, from Six Robblee's - and were about $72 for the pair. Fairly cheap in the overall scheme of things. These fenders come bare metal, with no brackets or attachment points of any kind. You have to figure that out for yourself.

So, we looked at what we were doing and tried to figure out how to attach them. We had an added complication, in that the axle is relocatable, so the fenders need to be relocatable too. So, what we decided to do is bolt them on using the same bolts that bolt the axle carriage in place. This way, the attachment points for the fenders are always where the attachment points for the axle carriage are. Make sense? Well, we also decided to have an additional attachment point, for added strength. This extra point uses the same bolt holes that were already in place for the axle carriage.

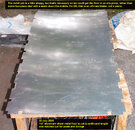

Anyway, so after figuring all this out, we needed to make some way for the fenders to bolt on. After rigging up some jigs to help us determine where we needed to put things, we welded two pieces of steel to the fenders. One is a rather thick piece, the other is a long piece of angle steel that runs along the front edge of the fender, which also has another piece welded to it, to make sort of an acute angle of steel that serves as the bracket. Anyway - we welded this stuff on and drilled holes as necessary and, voila - plain fenders have now become fenders that can be attached. I guess I should have taken some pictures before attaching them - but oh well. I'll take some later when I take them back off to do more painting and get pictures then.

I had the fenders powder coated black, to match the rear bumper. They sort of match the steel boxes, provide some contrast from the gray that the frame is powder coated, and also provide some contrast to the silver that I will paint the exposed sheet metal surfaces. Since I had everything powder coated at once, it's hard to say what portion of the cost is attributable to the fenders, but since I got such a good deal on the powder coating, it's not unreasonable to guess that maybe $100, at most, is attributable to the fenders.

Finally, I had the underside of the fenders lined with some spray on bedliner stuff. After checking with a few places in town, I went with the guy who applies the Signature 2020 product. It's supposed to be harder and better than things like RhinoLiner. The cost here was $70 for both fenders.

The fenders are easily removable, in that they are only held on with 3 bolts each, but to get to the bolts, you have to remove the tires - which means you have to jack it up. Sort of a pain in the ass, but it's not like I will be removing the fenders with any kind of frequency.

So, over all, I have a total of about $250 into the fenders, including the grade 8 1/2" bolts, lock nuts, and washers used to attach them and the powder coating and the spray liner on the undersides.

Some pictures attached.