So I have late model (1999) SA3 with a back-pressure valve. How do I monitor the filter status? I'm adding an hour meter, but I'd prefer something a bit more deterministic

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RIX SA3. How to monitor the filter stack

- Thread starter JohnN

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I have a spread sheet made by someone on here I can send you Monday when I get in the office?So I have late model (1999) SA3 with a back-pressure valve. How do I monitor the filter status? I'm adding an hour meter, but I'd prefer something a bit more deterministic

My Rix SA6 is very loud (well, the diesel engine that runs it is loud), so I wear bluetooth headphones with ear protection over. I have an alarm go off in my ear every 10-15 min to remind me to bleed the coalescers. I also start a timer that I use to input #'s into the spreadsheet.

The spreadsheet has inputs for both temp and time, as well as what your rated cf are for your particular filter and what cfm your compressor is rated at.

In the far right column is the theoretical % of filter life left.

The spreadsheet is based off of 18° rise over ambient as Bauer states in their literature. I have found that after running my compressor for a long time I get about an 11° rise, so 18° just builds in some conservatism. My filters are rated for 16,000 cf, so I change about ever 18 months or so.

Hope that helps? At least that's my current method.

Many thanks. The Rix manual for the SA3 says filter life can be extended to 4.5 x "normal" with the backpressure valve in place. Have you had a similar experience?

I would not run mine without a PMV in place. I have read / been told the sweet spot for that is somewhere around 2000-2200psi. I have mine set at 2200. The plus side is it squeezes most of the water out and in our case helps the 3rd stage piston build pressure to seat faster. (I actually have 2 PMV's installed, one right after the 3rd stage to build pressure and another after the filter stack to prolong filter life). The downside is your compressor is always running at that set pressure, so basically my compressor never sees anything below 2200 psi but for a brief second. (I don't bleed my stack unless changing filters. If I filled HP tanks to ~ 4000, I'll bleed off some pressure to bring it back down to 2200).

I don't know where the "4.5x" comes from. For any filter you'll get better life with cooler temperatures and keeping the stack under pressure. Take a look at the spreadsheet, play around with the numbers and see what I mean. I try really hard not to fill over 70F outside temp. The cooler the temps the longer the filter will last. Even @ 70F the filter is "seeing" ~ 88F. Mine is probably closer to 81F, but still a good bit warmer than ambiant.

I don't know where the "4.5x" comes from. For any filter you'll get better life with cooler temperatures and keeping the stack under pressure. Take a look at the spreadsheet, play around with the numbers and see what I mean. I try really hard not to fill over 70F outside temp. The cooler the temps the longer the filter will last. Even @ 70F the filter is "seeing" ~ 88F. Mine is probably closer to 81F, but still a good bit warmer than ambiant.

Attachments

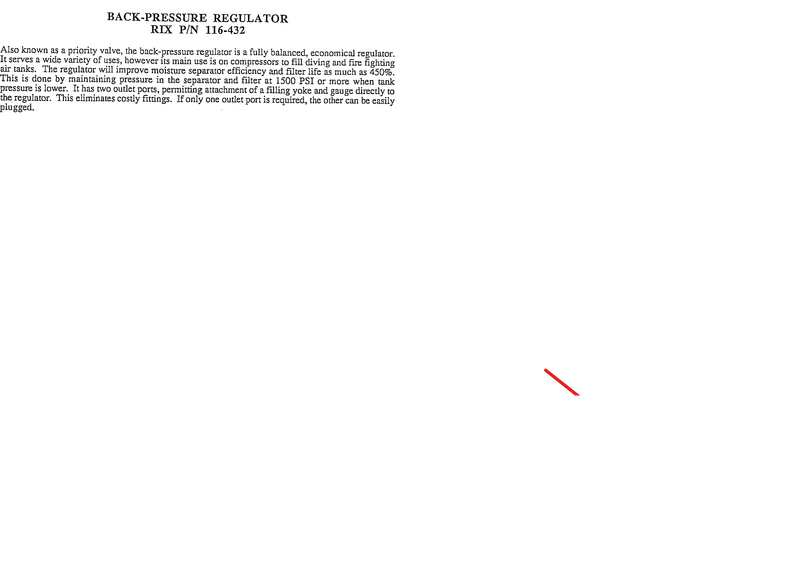

Here is the bit from the manual:

Filter life is virtually unaffected by ambient conditions. The final stage output is always 100% RH. Ambient will change your final discharge temp a little and so there is slight variation there but not a ton. Hours is an excellent way to gauge filter life. Your other option is to monitor pressure dew point and that will tell you more but that's an expensive route to take. (with that in place you can recharge your desiccant if you like.

As Rob said, run the PVM, you just should. The desiccant holds more water with more pressure so if you let it depressurize all the time it will release water after a pretty low amount of saturation and you will vastly reduce the useful life, 4x sounds conservatively correct.

As Rob said, run the PVM, you just should. The desiccant holds more water with more pressure so if you let it depressurize all the time it will release water after a pretty low amount of saturation and you will vastly reduce the useful life, 4x sounds conservatively correct.

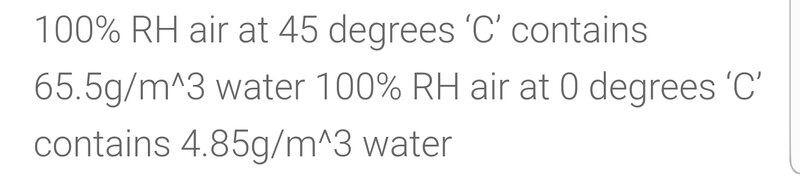

How is filter life not affected by ambient? I was under the impression that warmer air had a better propensity to hold water. From my personal testing my filter housing rises 11°F over ambient. I've tested this on 3 different occasions at different temperatures. I understand that no matter what the air will be 100% RH at the higher pressure, but that 100% RH changes based on temp.... correct?Filter life is virtually unaffected by ambient conditions. The final stage output is always 100% RH. Ambient will change your final discharge temp a little and so there is slight variation there but not a ton. Hours is an excellent way to gauge filter life. Your other option is to monitor pressure dew point and that will tell you more but that's an expensive route to take. (with that in place you can recharge your desiccant if you like.

As Rob said, run the PVM, you just should. The desiccant holds more water with more pressure so if you let it depressurize all the time it will release water after a pretty low amount of saturation and you will vastly reduce the useful life, 4x sounds conservatively correct.

Here's a chart that shows ambient temp and the relationship to how much water it can hold.

My understanding is that the cooler the incoming air, the less water it can hold and the longer the filter will last.

Attachments

Here's a direct quote;

That’s at ambient pressure and freezing to super hot we’re talking modest changes in temp and, at pressure. At scuba pressures we’re talking grains per lb.Here's a direct quote;View attachment 803495

A compressor running in Florida vs a compressor running in Alberta, the compressor in Alberta would certainly get more life out of a cartridge due to the lower ambients, maybe even 2x. Keep in mind that most of these machine aren’t supposed to be operated in ambients greater than 95F. And the vast majority of these machines run in a room that’s going to be 80 to 90 F, with 70 as a typical lowest ambient.

The problem is how to monitor it. There is no good reliable way to monitor the moisture vs the cost of cartridges so the recommendations are based off worst case, 95 ambient and the loss of cartridge life is ultimately worth it given all the other costs involved. Most cartridges give excellent output vs cost so hours are the best indicator to go by. If you are keeping the ambient extra low and wanted to risk using cartridges longer, I guess it wouldn’t be that risky but for the cost of a cartridge, doesn’t seem worth the savings.

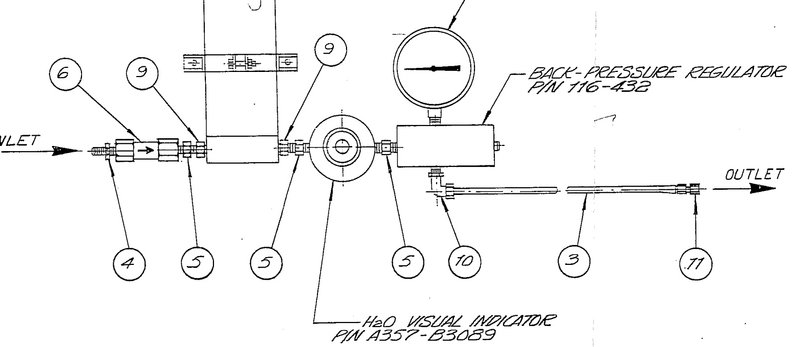

So there is a sight-glass type gizmo (H20 Visual Indicator) that is supposed to change color when moisture is detected. For the Rix, am I safe in monitoring that and if it doesn't turn color, I should be good?

Similar threads

- Replies

- 0

- Views

- 252

- Replies

- 6

- Views

- 852

- Replies

- 7

- Views

- 1,494

- Replies

- 11

- Views

- 1,034

- Replies

- 12

- Views

- 983